Introduction:

Transformers play a crucial role in electrical power systems, allowing efficient transmission and distribution of electricity. One of the key components in a transformer is its core. In this article, we will dive into the world of transformer cores, exploring the different types of transformer core materials and their applications.

The Importance of Transformer Cores:

Transformer cores are responsible for transferring energy between circuits by magnetic induction. They provide a path for the magnetic flux generated by the alternating current in the primary winding to link with the secondary winding. The choice of core material determines the efficiency, size, and cost of a transformer. Let's explore some of the commonly used transformer core materials and their applications.

Iron Core Transformers - The Traditional Choice

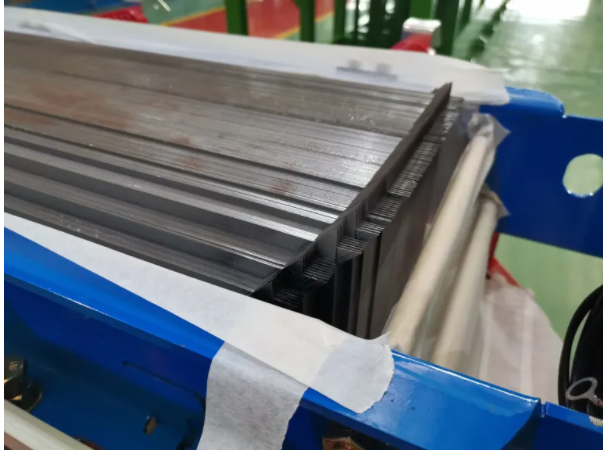

Iron cores have long been used in transformers due to their excellent magnetic properties. These cores consist of thin, laminated iron sheets called "transformer laminations." The sheets are insulated from each other to minimize eddy current losses, and they are stacked together to form the core.

Iron core transformers are widely used in power distribution systems, where high-voltage transmission lines need to be stepped down to lower voltages suitable for consumption. They are also used in industrial applications, such as welding machines and electric furnaces.

Silicon Steel Cores - Enhancing Efficiency

Silicon steel, also known as electrical steel, is a transformer core types of iron alloy that contains silicon. Adding silicon to iron reduces the core's magnetic losses, making transformers more efficient. Silicon steel cores exhibit lower hysteresis and eddy current losses compared to pure iron cores.

Transformers with silicon steel cores find applications in various fields, including power generation, distribution, and industrial processes. They are particularly useful in core of power transformer, where minimizing losses becomes crucial.

Amorphous Steel Cores - The Energy-Saving Alternative

Amorphous steel is a relatively newer material used in transformer cores. Unlike traditional transformers, which use laminated sheets of crystalline steel, amorphous steel cores are made from alloys without a specific crystalline structure. This unique composition reduces magnetic losses even further, resulting in energy savings.

Amorphous steel core transformers are widely employed in energy-efficient distribution transformers. These transformers contribute to a greener grid and reduce energy consumption, making them an excellent choice for sustainable power systems.

Ferrite Cores - Specialized Applications

Ferrite cores are most commonly used in applications involving high-frequency operations. Unlike iron or steel, ferrite cores are made from a ceramic-like material composed of iron oxide and other metals. They possess high electrical resistance and can operate at frequencies up to several megahertz.

Transformers with ferrite cores find applications in telecommunications, switch-mode power supplies, and radio frequency devices. They provide effective noise filtering and are crucial in suppressing electromagnetic interference.

Air Core Transformers - The Unconventional Approach

Air core transformers, as the name suggests, lack a solid core material. Instead, the primary and secondary windings are wound around a hollow non-conductive tube, relying solely on magnetic fields for energy transfer.

Although not as efficient as their iron or steel counterparts, air core transformers are used in applications where low inductance or high-frequency response is required. They find applications in RF amplifiers, wireless power transfer, and some audio electronics.

Conclusion:

Transformers come in various shapes and sizes, serving different purposes in countless electrical systems. The type of core material used plays a significant role in the overall performance and efficiency of transformers. Iron, silicon steel, amorphouse steel, ferrite, and even air cores all have their unique applications and strengths. By exploring these options, engineers can tailor transformer designs to specific needs, ensuring optimal energy transfer and reliability in numerous electrical applications.