What is Ferrite Core Transformer?

Ferrite core transformers are an essential component in many electrical and electronic devices, providing efficient power transfer and electrical isolation. These ferrite transformers are widely used in various applications, ranging from power supplies and inverters to telecommunications equipment and audio systems. The unique characteristics of ferrite core transformers make them highly desirable in modern technology, offering advantages such as compact size, high efficiency, and excellent noise suppression capabilities. In this article, we will explore the fundamentals of ferrite core transformers, their construction, operating principles, and applications.

The Basics of Ferrite Core Transformers

A ferrite core transformer is a type of electromagnetic device that transfers electrical energy between two or more circuits by electromagnetic induction. It consists of a primary winding, a secondary winding, and a magnetic core made of ferrite material. The primary winding is connected to the input voltage source, while the secondary winding is linked to the output load. The primary and secondary windings are physically separated but magnetically coupled through the ferrite core, allowing energy transfer from the primary to the secondary circuit.

Ferrite core transformers offer several advantages over transformers with other transformer core materials. Ferrite itself is a ceramic compound made primarily of iron oxide (Fe2O3), combined with other metal oxides. This composition results in its desirable magnetic properties, such as high magnetic permeability, low eddy current losses, and high electrical resistance. The unique characteristics of ferrite make it well-suited for high-frequency applications, where it exhibits minimal magnetic losses and core saturation.

Types of Ferrite Core Transformers

1. Nickel Zinc (NiZn): They have higher resistivity compared to MnZn ferrites. They are used in electrical applications when the frequency ranges between 2 MHz to several hundred MHz and are suitable for inductors above 70 Mhz.

2. Manganese Zinc (MnZn): They have higher saturation levels and higher permeability than NiZn ferrites. These are suitable for applications that have an operating frequency of less than 5MHz. Also, their impedance makes them ideal for inductors up to 70 MHz.

3. Lamination/ Amorphous & Nanocrystalline: The lamination transformers are primarily used in inverters, welding sets, and UPS.

4. Sand Dust: These are high-frequency Choke Coils ideally used with ferrites only.

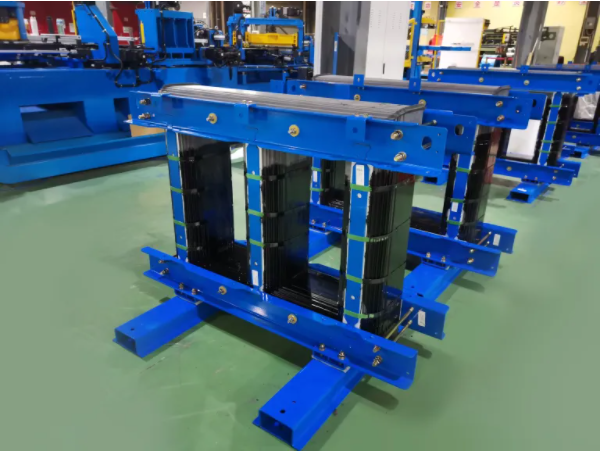

The Construction of Ferrite Core Transformers

Ferrite core transformers have a relatively simple construction compared to other ferrite transformer types. The core itself is typically toroidal (donut-shaped) or E-I-shaped, depending on the specific application requirements. The core is constructed by stacking multiple thin layers or laminations of ferrite material, which are coated with an insulating layer to reduce eddy currents. The laminated core design further improves the transformer's efficiency and reduces losses.

The primary and secondary windings are wound around the ferrite core, ensuring a high degree of magnetic coupling between them. Both windings consist of insulated copper wire, with the number of turns in each winding determined by the desired voltage ratio. The primary winding typically has more turns than the secondary winding, allowing for step-up or step-down voltage conversion.

The Operating Principles of Ferrite Core Transformers

Ferrite core transformers operate based on the principles of electromagnetic induction. When an alternating current (AC) flows through the primary winding, it produces an alternating magnetic field in the ferrite core. This magnetic field then induces a voltage in the secondary winding, proportional to the turns ratio between the windings. The polarity of the induced voltage depends on the direction of the magnetic field and the winding configuration.

Efficiency is a crucial consideration in ferrite transformer design, and ferrite core transformers excel in this aspect. The high magnetic permeability of ferrite allows for effective magnetic coupling between the windings, reducing energy losses during the transfer process. The low eddy current losses of ferrite further enhance efficiency, minimizing energy dissipation as heat and maximizing power transfer.

The Advantages of Ferrite Core Transformers

Ferrite core transformers offer several advantages that make them highly desirable in various applications. Here are some key benefits of using transformer ferrite core:

1. Compact Size: Ferrite core transformers are known for their compact size, making them an excellent choice for space-constrained applications. The efficient magnetic coupling and low losses of ferrite allow for reduced core size without compromising performance.

2. High Efficiency: The unique magnetic properties of ferrite contribute to high efficiency in power transfer. Ferrite core transformers ensure minimal energy loss and heat generation, resulting in more efficient electrical systems.

3. Noise Suppression: Ferrite core transformers exhibit excellent noise suppression capabilities, making them ideal for applications where electromagnetic interference (EMI) needs to be minimized. The intrinsic magnetic properties of ferrite help to attenuate high-frequency noise and provide cleaner power delivery.

4. Wide Frequency Range: Ferrite core transformers are specifically designed for high-frequency applications, typically ranging from a few kilohertz to several megahertz. They maintain their magnetic properties across this wide frequency range, ensuring consistent performance and reliable operation.

5. Temperature Stability: Transformer ferrite core are known for their excellent temperature stability. The properties of ferrite materials remain relatively stable over a wide temperature range, allowing for consistent performance in various operating conditions.

The Applications of Ferrite Core Transformers

High frequency ferrite transformer cores find applications in numerous electronic and electrical systems due to their unique characteristics. Here are some common applications where ferrite core transformer are used in:

1. Power Supplies: Ferrite core transformers play a crucial role in power supply systems, converting high voltage to low voltage or vice versa. They ensure efficient power transfer and provide electrical isolation between the input and output circuits, enhancing safety and reducing noise.

2. Inverters: In renewable energy systems like solar or wind power, ferrite core transformers are employed in inverters to convert DC power to AC power. These transformers help regulate voltage levels, provide galvanic isolation, and facilitate efficient power conversion.

3. Telecommunications: Ferrite core transformers are used extensively in telecommunications equipment, such as modems, routers, and telephony devices. They are employed for impedance matching, DC isolation, filtering, and noise suppression.

4. Audio Systems: Ferrite core transformers are commonly found in audio systems, including amplifiers, mixers, and speakers. They assist in audio signal transmission, impedance matching, and ground loop isolation, ensuring high-quality sound reproduction.

5. Switched-Mode Power Supplies (SMPS): SMPS, which are widely used in electronic devices, rely on high frequency ferrite transformer core for efficient power conversion. These transformers help regulate voltage, reduce electromagnetic interference, and enhance power supply efficiency.

In Summary

Ferrite core transformers are an integral part of modern electrical and electronic systems, enabling efficient power transfer, electrical isolation, and noise suppression. The unique characteristics of ferrite materials, such as high permeability, low losses, and excellent temperature stability, make them well-suited for high-frequency applications. From power supplies and inverters to telecommunications equipment and audio systems, ferrite core transformer plays a vital role in a wide range of applications. Their compact size, high efficiency, and noise suppression capabilities make them a preferred choice for many designers and engineers in today's technology-driven world.