Explore the essential guide to slitting line machines. Learn about their functionality, key components, and diverse applications in the industry.

Slitting line machines are pivotal in modern manufacturing, offering precision and efficiency in material processing. These machines are integral to the production of a wide array of products by slitting various materials, such as metal, paper, and plastic, into narrower strips. The versatility and reliability of slitting line machines make them invaluable across diverse sectors including automotive, packaging, and electronics.

At the forefront of this technology is Canwin, a renowned provider known for its innovative solutions and robust machinery. Canwin's slitting line machines are designed with cutting-edge technology to meet the highest standards of precision, catering to a global clientele seeking optimal productivity and minimal downtime.

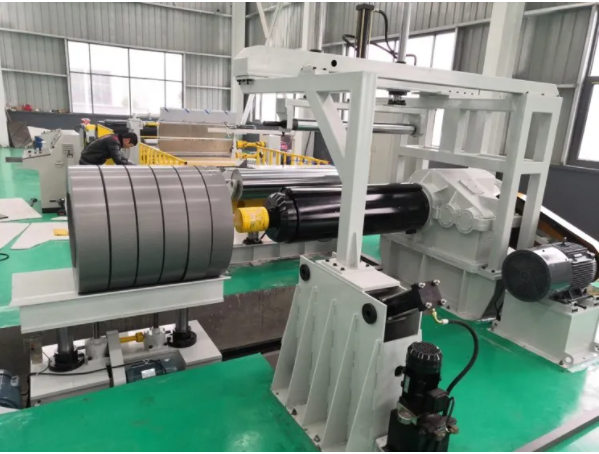

A slitting line machine is a sophisticated device used to cut wide rolls or coils of material into narrower bands of specified widths. This process is crucial for companies looking to resize their material efficiently without compromising quality. Essentially, the machine unrolls the material, slits it according to specified widths using sharp blades or lasers, and then re-rolls it into smaller coils.

In terms of material processing, slitting line machines facilitate a streamlined workflow by enabling quick size adjustments, maintaining material integrity, and supporting high-volume production runs. The ability to perform precise cuts and handle various material types underscores the machine’s role as an indispensable asset in modern manufacturing setups.

Slitting line machines comprise several key components that work together to ensure the efficient processing of materials. Each component is crucial for the accurate and rapid production of slit materials.

1. Uncoiler: The uncoiler, or decoiler, is the first component in the slitting line. It holds and unwinds the large coil of material, preparing it for the slitting process. The uncoiler ensures that the material is fed into the slitter at a consistent and controlled rate, preventing material damage and ensuring precision.

2. Slitter: The slitter is the heart of the machine. It can be equipped with various types of cutting blades, such as rotary shears, which are ideal for heavy gauge materials, and razor blades, which are suited for thinner, more delicate materials. The choice of slitter type depends on the material characteristics and the required precision of the cut. Canwin’s slitting line machines are designed with state-of-the-art blade technology that can be adapted to a wide range of industrial needs, ensuring clean and precise cuts.

3. Recoiler: Following the cutting process, the recoiler rewinds the slit materials into smaller, easy-to-manage coils. This component plays a critical role in maintaining the tension and alignment of the material, which is essential for the quality of the final product. The recoiler's precise control mechanisms, developed by Canwin, allow for tight and orderly coils, reducing material wastage and improving overall efficiency.

By integrating these components with precision engineering, Canwin enhances the functionality and reliability of its slitting line machines, setting new standards in the manufacturing industry.

Understanding the slitting process is essential for optimizing production and ensuring the highest quality of the final product. Here’s a detailed walkthrough of how materials are processed in a slitting line, highlighting the efficiency and speed of Canwin machines:

1. Loading the Material: The process begins with loading the master coil onto the uncoiler, which securely holds the coil and ensures it unwinds smoothly.

2. Material Feeding: The unwound material is then fed into the slitter through a series of rollers that maintain the material’s tension and alignment.

3. Slitting: As the material passes through the slitter, the chosen blades make precise cuts according to pre-set widths. This step is critical and relies on the sharpness and accuracy of the blades. Canwin’s advanced blade technology ensures that each cut is clean and precise, minimizing burrs and deviations.

4. Rewinding: After slitting, the material strips are carefully guided to the recoiler, where they are rewound into smaller coils. The recoiler’s tension control system, perfected by Canwin, ensures that the coils are tight and well-organized without damaging the material.

5. Quality Inspection: The final step involves inspecting the slit coils for any defects and ensuring they meet the specified quality standards. Canwin’s slitting lines are equipped with sensors and monitoring systems that check the coil dimensions and surface quality in real time, facilitating immediate adjustments.

The efficiency and speed of Canwin’s slitting line machines not only increase production capacity but also ensure that each product meets the rigorous standards expected by industries worldwide.

Slitting line machines are versatile tools that serve a broad range of industries. Their ability to precisely cut materials into specific widths makes them indispensable in several key sectors:

1. Automotive: In the automotive industry, slitting line machines are used to cut metals for body panels, frames, and other structural components. The precision of these cuts is crucial for ensuring the structural integrity and fit of automotive parts.

2. Construction: The construction sector relies on slitting machine lines to process materials like steel and aluminum for roofing, siding, and framing. These materials must be cut to exact specifications to ensure they fit seamlessly into construction projects.

3. Paper: In the paper industry, slitting machines are essential for cutting large rolls of paper into narrower rolls used in printing, packaging, and converting applications. The ability to make clean, precise cuts is vital for maintaining the quality of the paper products.

4. Plastics and Films: These machines are also used to slit plastic films and foils used in packaging and insulation. The versatility of slitting machine line allows for the processing of various polymers and composites, which are crucial in multiple applications from food packaging to thermal insulation.

Canwin’s slitting line machines are designed to handle a diverse range of materials, providing reliable performance in high-demand environments. This adaptability ensures that industries can achieve high levels of productivity and efficiency.

Investing in high-quality slitting line machines like those offered by Canwin brings several significant benefits:

1. Precision and Quality of Output: Canwin’s machines are engineered with precision components that ensure each slit is accurate to the specified width, reducing material waste and ensuring that the final product meets exacting standards. This is crucial in industries where material specifications are tightly controlled.

2. Cost-effectiveness and Time Savings: High-quality machines maximize throughput and minimize downtime, directly impacting production efficiency. Canwin’s slitting machines are designed for ease of operation and quick setup, which reduces labor costs and enhances production cycles.

3. Durability and Less Maintenance: Canwin’s slitting line machines are built to last. Constructed from high-grade materials and incorporating the latest in wear-resistant technology, these machines require less maintenance, thereby reducing long-term operational costs. The robust design ensures that the machines can handle continuous use, even under challenging industrial conditions.

These benefits highlight why Canwin is the choice for businesses looking to enhance their manufacturing capability. The company’s commitment to quality and customer satisfaction ensures that each slitting line machine is a worthy investment, capable of meeting the demands of modern production environments.

Selecting the appropriate slitting line machine for your manufacturing needs involves several critical factors. Understanding these can help ensure you invest in a machine that not only meets your current production demands but also adapts to future requirements.

1. Material Type: Different materials require different types of slitting mechanisms. Metals, for instance, might need a robust rotary shear cutter, while thinner materials like paper or film could be better served by razor slitters. It's crucial to choose a machine that's optimized for the specific materials your industry works with to ensure precision and minimize wear and tear.

2. Material Thickness: The thickness of the material also plays a significant role in selecting the right slitter. Thicker materials require machines with higher power and stronger cutting capabilities, whereas thinner materials demand more finesse and accuracy to avoid damage during the slitting process.

3. Production Volume: Your production volume dictates the scale and speed of the slitting line machine required. High-volume environments benefit from machines with faster processing capabilities and more automated features to maintain consistent output without sacrificing quality.

By considering these factors and partnering with Canwin, businesses can ensure they select a slitting line machine that not only meets their current needs but also scales with their future growth. Canwin’s commitment to innovation and customer satisfaction makes them a preferred partner in the industry.

Slitting line machines are indispensable in today's diverse manufacturing landscape, offering unmatched precision, versatility, and efficiency. As prominent slitting line manufacturers, Canwin provides machines that play a critical role in numerous industries, from automotive to construction and beyond, processing a wide range of materials such as metals, films, and foils. The advantages of using high-quality slitting line machines like those provided by Canwin include enhanced precision, significant cost savings, and superior durability.

If you're looking to boost your production capabilities with a slitting line machine that is tailored to your specific needs, look no further than Canwin. Our team of experts is dedicated to providing customized solutions that integrate cutting-edge technology and robust design to meet the unique demands of your operations.

Visit our website at Canwin for more details and to schedule a consultation. Let us help you achieve operational excellence with a slitting line machine designed just for you.