Slitting line machines play a pivotal role in various industries, serving as the backbone of manufacturing processes. From automotive to construction and beyond, these machines are indispensable for transforming large coils of material into precise strips, catering to diverse industrial needs.

The significance of selecting the right supplier for your slitting line machine cannot be overstated, as it directly impacts your production efficiency and product quality. This article will explore the critical factors to consider when choosing a slitting line machine supplier, ensuring that your investment aligns with your specific needs and expectations.

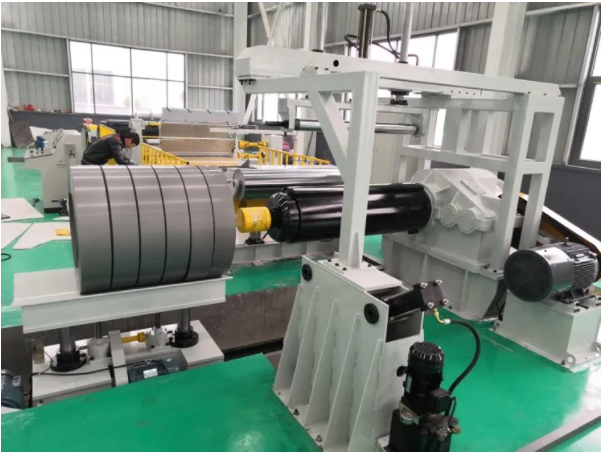

Before diving into the selection process, it's essential to comprehend what a slitting line machine is and its primary purpose. At its core, a slitting line machine is designed to slit large coils of material, such as steel or aluminum, into narrower strips with precise measurements. These strips, often referred to as "mults," serve as raw materials for downstream industrial processes. A typical slitting line machine comprises several key components, including a decoiler, slitter, and recoiler.

The decoiler unwinds the master coil, while the slitter head precisely cuts the material into narrow strips using rotary knives. The operator carefully inspects these mults to ensure they meet required specifications. Subsequently, the mults pass through a looping pit to guarantee stress-free and camber-free recoiling, crucial for maintaining material integrity. Finally, the mults are banded and packaged to meet customer requirements. Choosing the right slitting line machine is crucial to ensure seamless operations tailored to your specific needs.

To make an informed decision when selecting a slitting line machine supplier, you must first identify your unique requirements. Several factors should influence your choice, including the types of materials you will be processing, material thickness, and production capacity. Different materials require specific machine configurations and tooling, so it's essential to match your requirements with the machine's capabilities.

Furthermore, understanding your production goals and expectations is paramount. Consider factors such as the volume of material you intend to process daily, the desired strip widths, and the level of precision required. This clear understanding will serve as your compass when evaluating potential suppliers.

Choosing the right supplier is pivotal in ensuring the success of your slitting line machine investment. Start by conducting thorough research to identify reputable and reliable slitting line machine manufacturers & suppliers in the industry. Leveraging online searches, industry associations, and referrals from trusted sources can help you compile a list of potential suppliers.

Once you've compiled a list of potential slitting line machine suppliers, it's time to assess their qualifications. Several criteria should guide your evaluation, including the slitting line supplier's experience in the industry, their reputation, and relevant industry certifications. Experience is a valuable asset, as suppliers with a proven track record are more likely to provide reliable products and services.

A reputable slitting line machine supplier should also hold industry certifications and adhere to recognized quality standards. These certifications are indicative of their commitment to delivering high-quality equipment. Consider factors like ISO certifications and compliance with relevant industry regulations.

The quality of the slitting line machine is an important consideration. High-quality machines are not only more reliable but also contribute to superior end-product quality. In today's technology-driven landscape, it's essential to inquire about the technological capabilities of potential suppliers. Modern machines often incorporate advanced technology and innovative features that enhance efficiency and precision.

Ask potential slitting line machine manufacturers about the technological aspects of their machines, such as automation, control systems, and software. A slitting line machine supplier that keeps pace with technological advancements is more likely to provide you with a machine that meets your evolving needs.

Post-purchase support and service are critical aspects of your investment. A reliable supplier should offer comprehensive customer support, including maintenance, training, and troubleshooting assistance. Inquire about the customer support services provided by potential suppliers, ensuring they align with your needs.

A supplier's commitment to customer service reflects their dedication to ensuring your machine's optimal performance throughout its lifecycle. Prompt and effective support can minimize downtime and production interruptions, translating into cost savings and enhanced efficiency.

Budget constraints play a significant role in the decision-making process. While it's crucial to invest in a high-quality customized slitting line machine, it's equally important to strike a balance between quality and cost. Carefully evaluate the pricing structures offered by potential suppliers and consider the long-term return on investment.

Negotiating with suppliers can also help you secure the best value for your investment. Discuss pricing options, warranties, and potential customization to align the machine with your specific requirements. Keep in mind that the cheapest option may not always be the most cost-effective in the long run.

When considering a slitting line manufacturer & supplier for your china slitting line machine, CANWIN emerges as a trusted partner. With extensive experience and a stellar reputation for excellence, CANWIN brings a wealth of expertise to the table. Holding industry certifications, they adhere to rigorous quality standards, ensuring the reliability of their machines.

CANWIN's commitment to cutting-edge technology means their machines are equipped with state-of-the-art features and innovations. They offer comprehensive customer support, including maintenance and troubleshooting, and provide cost-effective solutions. By choosing CANWIN, you're investing in a slitting line supplier with a proven track record, a dedication to quality, and a focus on your long-term success.

Choosing the right slitting line machine supplier is a pivotal decision with far-reaching implications for your business. By understanding your unique requirements, conducting thorough research, and evaluating supplier qualifications, you can make an informed choice that aligns with your production goals and expectations.

Prioritize product quality, technological advancements, and customer support when assessing potential suppliers. While cost considerations are important, they should not overshadow the importance of investing in a high-quality machine that will serve your needs efficiently and reliably.

By following the outlined steps and considerations, you can navigate the process of choosing a customized slitting line machine supplier with confidence. Your investment in the right machine will contribute to the success and efficiency of your industrial operations, ensuring a brighter future for your business.