Dive into our in-depth guide exploring transformer core types. Learn about their unique characteristics, functions, and applications to make informed choices.

Transformers are ubiquitous in the world of electrical engineering and power distribution. They serve as the backbone of our electrical infrastructure, facilitating the efficient transmission of electricity from power plants to our homes and businesses. At the heart of every transformer lies a critical component - the core. Understanding transformer core types is essential for engineers, technicians, and anyone involved in the field of electronics, as it can make all the difference in achieving optimal performance and efficiency.

When it comes to transformers, it's not a one-size-fits-all scenario. Different applications demand different core materials and designs, each with its own set of characteristics, advantages, and limitations. In this comprehensive guide, we will take you on a journey through the fascinating world of transformer cores. We will delve into the various types available, shedding light on their distinct properties and the applications where they shine.

Whether you're a seasoned electrical engineer or someone simply curious about how transformers work, this guide will equip you with the knowledge you need to make informed choices in selecting the right transformer core for your specific needs. Join us as we unravel the intricacies of transformer core types and discover the crucial role they play in powering our modern world.

What is a Transformer Core?

Transformers are marvels of electrical engineering, essential in the transmission and distribution of electrical power. To understand the significance of transformer cores, it's crucial to grasp the fundamental concept of a transformer and the pivotal role cores play within these electrical systems.

At its core (pun intended), a transformer is a passive electrical device that transfers electrical energy between two or more circuits through electromagnetic induction. Its primary purpose is to increase or decrease voltage levels while maintaining power balance, making it a cornerstone in the efficient distribution of electricity.

Key Components of a Transformer:

1. Primary Coil: A transformer consists of two coils, often referred to as the primary and secondary windings. The primary coil is connected to the input voltage source, and it induces a magnetic field when an alternating current (AC) passes through it.

2. Secondary Coil: The secondary coil is connected to the load or the circuit where you need the transformed voltage. The changing magnetic field from the primary coil induces an electromotive force (EMF) in the secondary coil, resulting in voltage transformation.

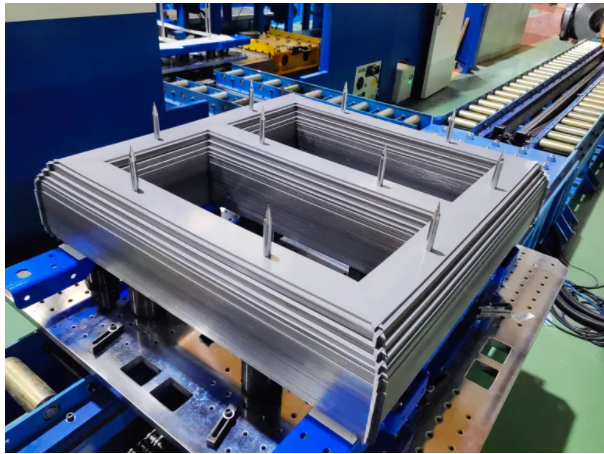

3. Core: Now, let's focus on the core. The core is the central component that surrounds both coils. Its primary function is to provide a path of low reluctance for the magnetic flux generated by the primary coil. In other words, it efficiently concentrates and directs the magnetic field, allowing for effective energy transfer between the primary and secondary coils.

Transformer cores are typically made from various transformer core materials, including iron, ferrite, air, and even specialized materials like amorphous alloys. The choice of core material significantly influences the transformer's performance characteristics.

Understanding the core's role is pivotal because it dictates the transformer's efficiency, size, and performance in various applications. Different transformer core materials have distinct magnetic properties, which affect factors such as energy losses, saturation levels, and frequency response.

Types of Transformer Cores

Transformers, the unsung heroes of our electrical systems, rely on various core material of transformer to perform their vital functions. Here's an overview of the primary types of transformer core:

1. Iron Core

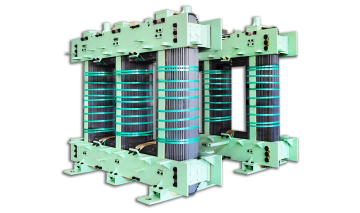

Transformer iron cores stand as the cornerstone of transformer technology, offering a stable and reliable solution for numerous applications.

Characteristics and Properties of Iron Cores:

Iron cores possess the following key characteristics and properties:

a. High Magnetic Permeability: Iron is highly permeable to magnetic flux, which ensures efficient magnetic field transfer between the primary and secondary windings.

b. Low Hysteresis Loss: Iron cores exhibit minimal hysteresis loss, meaning they don't dissipate much energy as heat during magnetic reversals, resulting in high efficiency.

Applications of Iron Cores:

Types of iron cores find widespread use in applications requiring high efficiency, precision, and reliability, including:

a.Power Distribution Transformers: These cores are the backbone of electrical grids, stepping up and down voltage for transmission and distribution.

b. Inductors and Chokes: Iron cores are used in inductors to store energy in various electronic devices.

Advantages of Iron Cores:

●High efficiency due to low core losses.

●Reliable and stable performance.

●Well-suited for medium and high-frequency applications.

Drawbacks of Iron Cores:

●Heavier and bulkier compared to some other core types.

●Sensitive to overloads and can saturate under excessive current.

2. Ferrite Core

Ferrite cores, made from specialized ceramic materials, offer unique advantages in high-frequency applications.

Distinctive Features and Benefits of Ferrite Cores:

Ferrite cores possess distinctive features and benefits, including:

a. High Magnetic Permeability at High Frequencies: Ferrite cores excel at conducting magnetic flux, making them ideal for high-frequency applications.

b. Low Eddy Current Loss: Ferrites exhibit low eddy current losses due to their insulating properties, ensuring minimal energy dissipation.

Applications Where Ferrite Cores Excel:

Ferrite cores are prominently used in:

a. Switch-Mode Power Supplies: Their high-frequency capabilities make ferrite cores a preferred choice for compact, efficient power supplies.

b. Radio Frequency Transformers: Ferrite cores are crucial components in RF circuits, enhancing signal performance.

Limitations and Considerations:

While ferrite cores offer many advantages, it's essential to consider their limitations:

●Limited suitability for low-frequency applications.

●Can be brittle and more prone to physical damage compared to other core types.

3. Air Core

Air cores are unique in their simplicity, offering advantages in specific applications where low interference and precise tuning are crucial.

Explaining the Concept of Air Cores and Their Properties:

Air cores rely on air as the medium for conducting magnetic flux, making them different from their iron and ferrite counterparts. Key properties include:

a. Low Permeability: Air has a very low magnetic permeability, resulting in lower inductance compared to cores with magnetic materials.

b. Minimal Eddy Current Loss: Air cores exhibit virtually no eddy current loss due to the absence of magnetic materials.

Specialized Applications Benefitting from Air Cores:

Air cores find their niche in applications where low interference and precise tuning are critical, such as:

a. RF Coils and Antennas: Air cores are essential components in radio frequency circuits, where precise tuning and minimal interference are paramount.

b. High-Q Inductors:In applications requiring high-quality factor (Q-factor) inductors, air cores shine.

Comparing Air Cores with Other Types:

In terms of efficiency and suitability, air cores offer advantages in specific scenarios. However, they also have limitations, especially in terms of inductance compared to magnetic core-based transformers.

4. Toroidal Core

Toroidal cores, with their unique doughnut-shaped design, offer advantages in terms of size and reduced electromagnetic interference.

Describing Toroidal Cores, Their Design, and Advantages:

Toroidal cores feature a circular cross-section with windings wrapped around them. This design has several advantages:

a. Reduced Electromagnetic Interference: The closed-loop magnetic path minimizes stray magnetic fields, reducing interference with nearby components.

b. Compact Size: Toroidal transformers are more compact and space-efficient compared to some other core types.

Real-World Examples of When Toroidal Cores Are Preferred:

Toroidal cores are preferred in various scenarios, including:

a. Audio Equipment: Many high-quality audio amplifiers and devices use toroidal transformers for their compact size and reduced noise.

b. Power Transformers:Toroidal cores are also used in power transformers when space constraints are a consideration.

Factors like Size and Cost Efficiency:

Choosing a toroidal core depends on specific project requirements, considering factors like size, cost efficiency, and the need for reduced electromagnetic interference.

How to Choose the Right Transformer Core

Selecting the appropriate transformer core types for a specific project is a crucial decision that impacts performance, efficiency, and overall functionality. To make an informed choice, consider the following factors, including frequency, power requirements, and size constraints:

1. Operating Frequency:

The operating frequency of your application plays a pivotal role in determining the ideal transformer core type:

a High-Frequency Applications (e.g., >1 MHz): Ferrite cores excel in these scenarios due to their high magnetic permeability at higher frequencies. They minimize losses and provide efficient power transfer.

b. Medium-Frequency Applications (e.g., 10 kHz - 1 MHz): Iron cores are a reliable choice for medium frequencies. They offer good efficiency and are suitable for most general-purpose applications.

c Low-Frequency Applications (e.g., <10 kHz):Iron cores are typically preferred for low-frequency applications due to their high magnetic permeability, ensuring efficient energy transfer.

d. RF Applications (Radio Frequencies): Air cores are often used in RF circuits and antennas, as they minimize interference and offer precise tuning capabilities.

2. Power Requirements:

Consider the power rating and load conditions of your project:

a. High-Power Applications: Transformer iron cores and amorphous alloy cores are suitable for high-power transformers, as they offer excellent efficiency and can handle substantial power loads.

b. Low-Power Applications: Ferrite cores, especially in small electronic devices, are ideal due to their low core losses and efficiency at lower power levels.

3. Size Constraints:

The available space within your project can dictate the choice of power transformer core:

a. Space-Efficient Solutions: Toroidal cores are compact and fit well in limited spaces, making them an excellent choice when size constraints are a concern.

b. Larger Transformers: Iron cores are suitable for larger transformers, where size may not be a primary constraint.

4. Temperature Considerations:

Examine the temperature conditions of your application:

a. High-Temperature Environments: Ferrite cores tend to operate well in high-temperature environments, as they have good thermal stability.

b. Cooler Environments: Iron cores can be more robust in cooler settings, where their efficiency remains high.

5. Cost Considerations:

Budget is always a factor in any project. While iron cores are generally cost-effective, specialized cores like amorphous alloy cores may come at a premium but offer exceptional energy efficiency, potentially offsetting initial costs through long-term energy savings.

Conclusion:

In conclusion, transformer core types are the backbone of electrical engineering, influencing the efficiency and performance of electrical systems. Understanding the distinctions among Iron Cores, Ferrite Cores, Air Cores, and Toroidal Cores is paramount for making informed decisions in various applications.

Selecting the right core type involves careful consideration of factors such as operating frequency, power requirements, size constraints, and environmental conditions. By doing so, you can optimize the functionality and efficiency of your electrical projects.

In the ever-evolving landscape of technology, the choice of the appropriate transformer core type continues to be a crucial aspect of electrical engineering. Armed with this knowledge, you are now better prepared to navigate these complexities and contribute to the advancement of efficient and sustainable electrical systems. Make informed choices and let your projects illuminate the path to a brighter and more efficient future in electrical engineering.