Amacandelo asisiseko se-A Transformer

1. Ukwakheka okusisiseko kwe-transformer

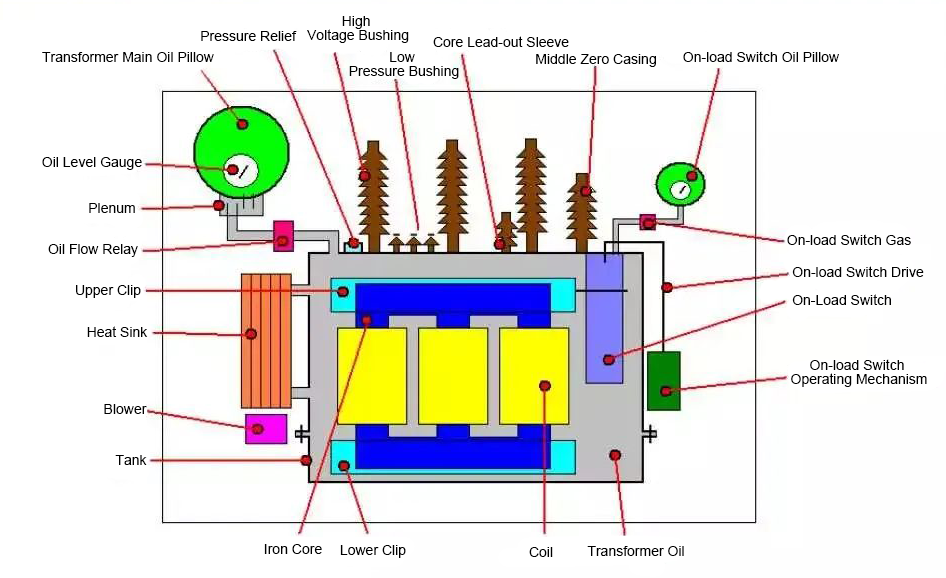

Ubume obusisiseko boguqulo lwamandla amakhulu ludla ngokwahlulwa lube ngamacandelo asixhenxe alandelayo:

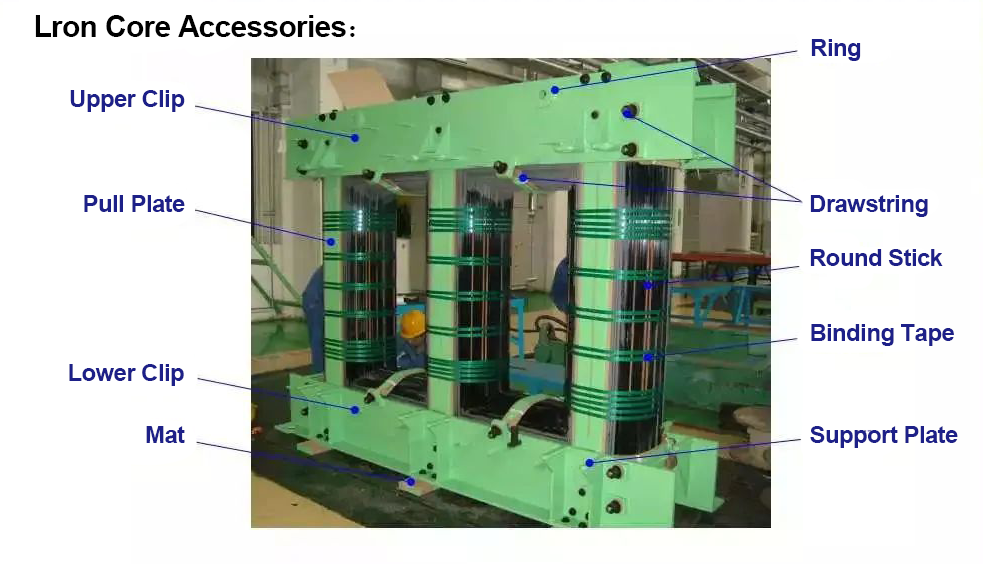

1.Inxalenye engundoqo yoku-1 ibandakanya ikholamu, idyokhwe kunye nesixhobo sokubambelela esenziwe ngokupakishwa kwamaphepha entsimbi yesilicon.

I-2.I-Winding inxalenye enye ibandakanya iingcingo ezikhokelayo zesigaba ngasinye sokujikeleza kunye nokudibanisa kwayo

3.Inxalenye ye-Insulation - kuquka i-oyile kunye ne-insulation yephepha phakathi kwecandelo ngalinye kunye nelo

I-4.Inxalenye yetanki ye-Fuel - ngaphezu kwetanki yamafutha ngokwawo, iquka iitanki zokugcina i-fuel, iibrakethi, njl.

I-5.Inkqubo yokupholisa - kuquka i-cooler okanye i-radiator, ipompo yeoli, i-fan, i-manifold, njl.

6.Izixhobo zokulinganisa - kubandakanywa i-thermometers yesignali, i-transformers yangoku, i-oil level gauges, njl.

I-7.Izixhobo zokukhusela - i-pressure releasers, i-gas relays, i-absorber absorbers, njl.

Phakathi kwazo, iinxalenye ezimbini zokuqala nazo zingabizwa ngokuba yinxalenye yesiphaluka semagnethi kunye nenxalenye yesiphaluka, ezo ziyinxalenye esisiseko.

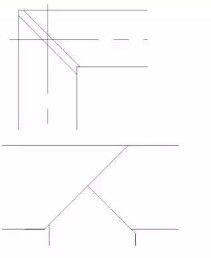

Umzobo weSchematic wamacandelo aphambili e-transformer

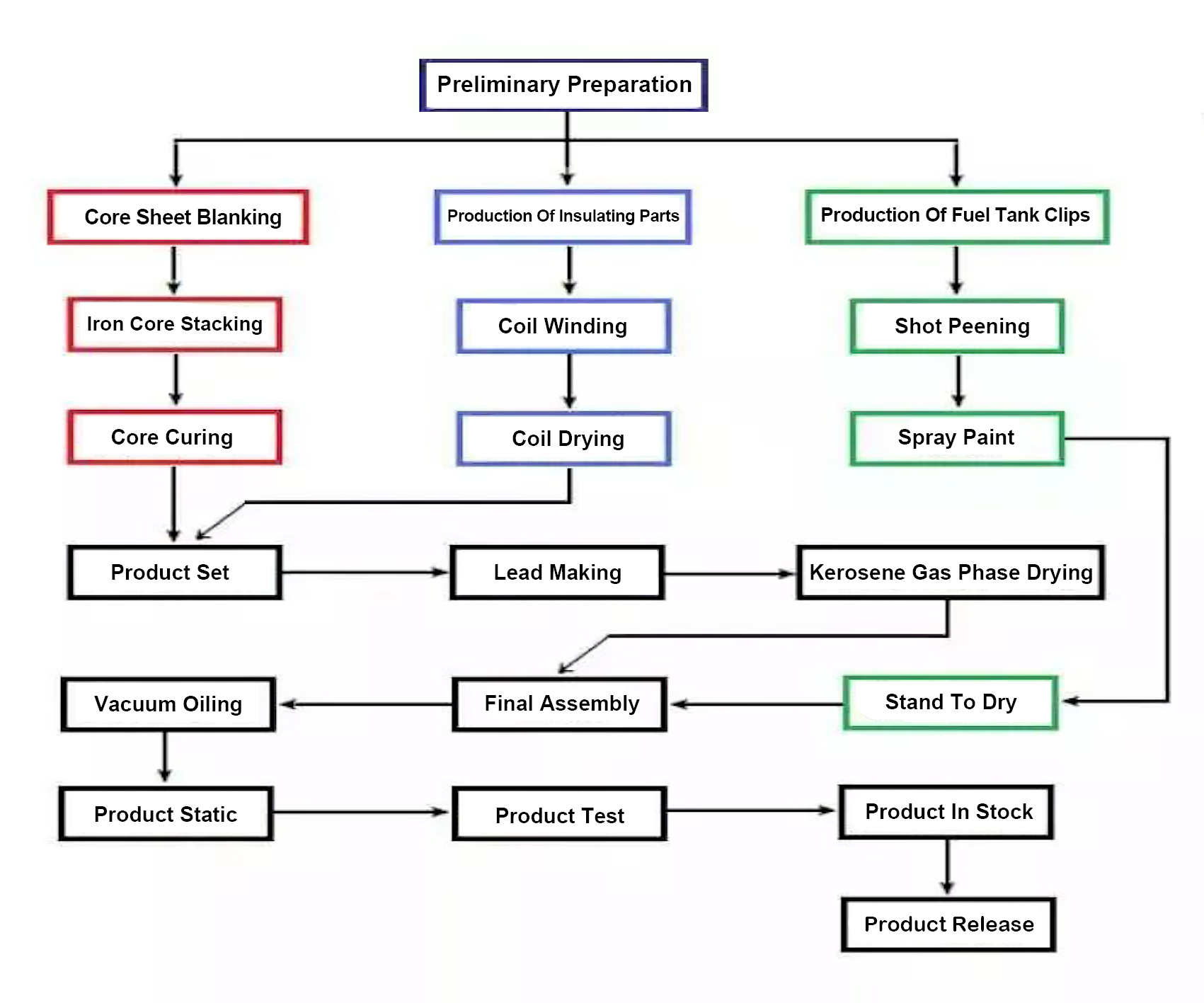

Inkqubo yokwenziwa kweTransformer

Undoqo weTransformer

Umxholo oyintloko wokungeniswa kwengundoqo ye-transformer kukusika, ukupakisha, ukulungiswa kwe-transformer core kunye ne-teknoloji yakamuva yokupakisha ukunciphisa ukulahlekelwa komthwalo.

2. Undoqo weTransformer

Ingundoqo yinxalenye esisiseko ye-transformer. Iqukethe i-conductor magnetic kunye nesixhobo sokubambelela. Inemisebenzi emibini: ngokomgaqo, i-magnetic conductor ye-iron core yi-circuit magnetic ye-transformer, eguqula amandla ombane wesekethe yokuqala ibe yimagnethi yamandla, kwaye ukusuka kumandla ayo ombane ukuya kumandla ombane wesekethe yesibini. , eyindlela yokuguqula amandla. Ngokwesakhiwo, i-iron core isekela onke amacandelo angaphakathi kwi-transformer, njengomzimba kunye nokukhokela.

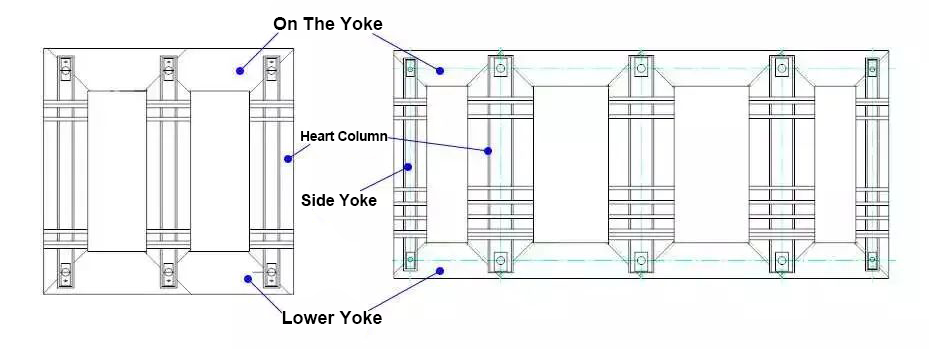

Ingundoqo yentsimbi ye-transformer yisakhiwo esivaliweyo esakhiweyo. Inxalenye yekhoyili ibizwa ngokuba yintsika engundoqo. Inxalenye engayifakiyo i-coil kwaye idlala kuphela indima yokuvala i-circuit magnetic ibizwa ngokuba yi-iron giant.

Iintlobo zeentsimbi zentsimbi

Ngokwendawo ehambelanayo ye-winding kunye ne-iron core, i-iron core inokwahlulwa ibe ngamacandelo amabini: uhlobo oluphambili kunye nohlobo lweqokobhe. Kuphela i-iron yodidi lwentliziyo yaziswa apha okwangoku. Kwi-single-phase transformers, i-core yentsimbi ineendlela ezininzi zesakhiwo, ezifana nekholamu ezimbini kunye nekholamu ezimbini, ikholomu enye-ikholomu emine, kunye nekholamu ephindwe kabini.

Kwiziguquli zesigaba sesithathu, i-core yentsimbi ineendlela ezininzi zesakhiwo ezifana nekholamu ezimbini kunye nekholamu ezimbini (inqanaba lesithathu-ikholomu), ikholomu emithathu kunye ne-four-column (isigaba sesithathu sekholomu). Ukukhethwa kwesakhiwo esingundoqo sichongwa ngokwezinto ezibanzi ezifana nokulungelelaniswa okufanelekileyo kwee-windings ezahlukeneyo, ukugcinwa kwezinto eziphathekayo, kunye nokudibana nokuphakama kokuthutha. I-Bypass inokunciphisa i-wave yesihlanu kunye neyesixhenxe kwi-flux yokuvuza kunye ne-magnetizing yangoku.

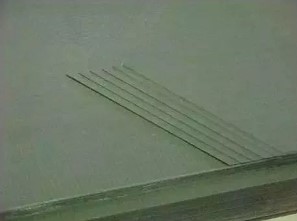

Umtya wentsimbi yombane (icwecwe lentsimbi yesilicon):

Izinto ezisetyenziselwa intsimbi engundoqo yomqhubi wemagnethi yintsimbi yombane enomxholo ophezulu wesilicon, ekwabizwa ngokuba yi-silicon steel sheet.

Kukho iintlobo ezimbini ze-silicon sheet sheets: ukuqengqeleka okubandayo kunye nokuqengqeleka okushushu, apho amaphepha entsimbi aqengqiwe abandayo ahlulwe abe ziindidi ezimbini: ezingajoliswanga kwaye zijolise-

Iimpawu zamagnetic zamaphepha ensimbi ye-silicon eshushu-eshushu zihlwempuzekile, ukuxinana kwamagnetic kungafikelela kuphela kwi-1.5T, kwaye ilahleko yeyunithi inkulu kakhulu, ngoko ayisasetyenziswa. Icwecwe le-silicon yentsimbi eqengqelekayo eqengqelekayo linomkhombandlela ocacileyo, ukugcwala okuphezulu koxinaniso lwemagnethi, ilahleko encinci yeyunithi kunye nomthamo wokuvuselela iyunithi, kwaye ngoku isetyenziswa ngokubanzi.

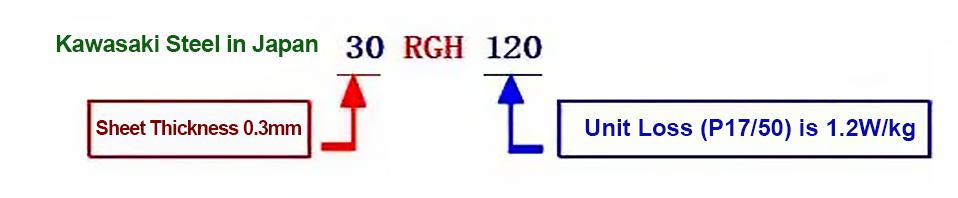

Ubukhulu beshiti lentsimbi yentsimbi eqengqelekayo egotyiweyo lunezibaluli eziliqela, ezifana ne-0.35mm, 0.3mm, 0.27mm, 0.23mm, njl. Elona lisetyenziswa rhoqo yi-0.3mm, kwaye liya lisiba lincinci kwaye lincinci, kwaye eyona njongo kukunciphisa ilahleko enqamlezileyo engekho mthwalo.

·Okwangoku, ezona ndawo zivelisa i-silicon steel sheets yi-Japan, iNtshona Yurophu, iRashiya, iSouth Korea kunye ne-Wuhan Iron and Steel yasekhaya.

Iinkcukacha zamaphepha entsimbi ye-silicon aqengqeleke ngokubanda amelwe ikakhulu bubunzima kunye nelahleko yeyunithi (W/kg) xa i-50Hz yoxinano lwemagnethi eyi-1.7T, umzekelo:

·Iphepha elitsha le-silicon yentsimbi kusetyenziswa i-laser irradiation kunye neteknoloji yokukrola ngoomatshini

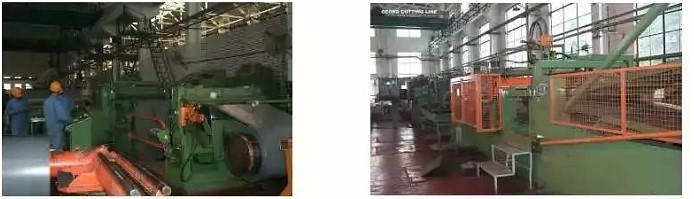

Ukuchetywa kwe-transformer core silicon sheet yentsimbi:

Xa impahla ye-silicon yentsimbi ingena kumzi-mveliso, yicoil enobubanzi obumalunga ne-1000mm. Kufuneka isikwe kwimilo efunekayo ngezixhobo ezikhethekileyo zokucheba (ezifana ne-German Georger wire). Ibhula yokucheba yephepha ngalinye kufuneka ingabi ngaphezu kwe-0.02mm.

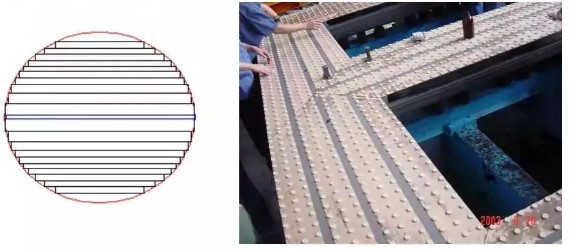

Ukupakishwa kweentsimbi zentsimbi:

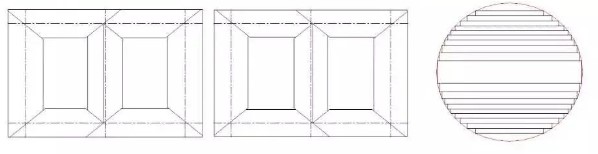

● Ngenxa yokuba i-coil ye-core type transformer iyisetyhula, icandelo lekholomu engundoqo kufuneka kwakhona libe setyhula, kodwa kunzima ukuvelisa kunye nokungabi namali, ngoko ke lenziwe kwi-stepped (graded cylindrical type). Inyathelo ngalinye lenza uxande, kwaye umda wangaphandle ubekwe kwisangqa esinye. Inani lamanyathelo linomda othile, ekufuneka uqwalaselwe ngokubanzi ngokweenzuzo zoqoqosho.

●Xa iintsimbi zipakishwe, intsika engundoqo kunye nenxalenye engundoqo yentsimbi yedyokhwe yentsimbi zibotshwa ngokutshintshatshintshayo ngeqhekeza elinye okanye eziliqela, ukuze amalungu ezimpundu zamaleko angasentla nasezantsi e-silicon agxadazele aze agqunywe. kunye. I-excitation yangoku kunye nelahleko engekho mthwalo iyancitshiswa ngelixa iphucula amandla.

Umjikelo wentsimbi yombindi wentsimbi:

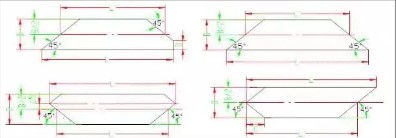

· Okwangoku, i-transformer core ithatha ifom ye-oblique epheleleyo, oko kukuthi, i-junction yekholomu engundoqo kunye nejoka yentsimbi yi-45 °. Le fomu edibeneyo ifaneleka ngokupheleleyo kwiimpawu ze-silicone sheet sheet yentsimbi esetyenziswa kakhulu ngoku. Yenza i-magnetic circuit ihambelane kangangoko kunokwenzeka.

·Kwii-cores ze-transformer ezinkulu ezinamajoyini apheleleyo e-miter, ukupakishwa ngokuqhelekileyo kuqhutywa ngendlela yamanqanaba amabini adibeneyo. Ukuze kuphuculwe ngakumbi iimpawu zokungabikho komthwalo we-core transformer, ifom ye-multi-level seam ye-core yenziwa, oko kukuthi, i-StepLap core.

Kwisiseko se-laminated, i-seams ye-silicon sheet sheets iyaphazamiseka. Xa i-magnetic flux yeqhekeza elithile idibana nomsantsa womoya kumthungo, ukuxhathisa kwemagnethi komsantsa womoya kungamawaka aliqela aphindwe kaninzi kunokweshiti lentsimbi yesilicon. Uninzi lwe-flux ludlula kumaphepha entsimbi e-silicon akufuphi adibanisa eli khonkco. Uguqulo lwemagnethi yantlandlolo yokukhanya kumalungu okuvala ibhulorho kunye nemagnethi yokuqukuqela yongamele phezulu. Uxinaniso lunokufikelela kwi-saturation, ukwenzela ukuba ukulahlekelwa komthwalo kunye nokungabikho komthwalo kwindawo edibeneyo (oko kukuthi, indawo) yanda ngokukhawuleza, ukwenzela ukuba ilahleko epheleleyo yokungabikho komthwalo iyanda.

I-Step lap yitekhnoloji entsha yokulambisa eyamkelwe kulo nyaka, enokuphucula ukuxinana kwamagnetic kwiphepha lentsimbi yesilicon kwindawo edibeneyo, ngaloo ndlela inciphisa ngempumelelo ilahleko yomthwalo kunye nengxolo yenxalenye ephambili.

Ukugquma okungundoqo:

I-insulation ye-iron core inefuthe elithe ngqo kumgangatho wemveliso ye-transformer core. I-insulation ye-iron core inokwahlulwa ibe ngamacandelo amabini: i-insulation phakathi kwamaphepha kunye ne-insulation phakathi kwe-laminations kunye ne-structural parts.

Ukufakwa kwe-inter-chip kufezekiswa ikakhulu ngemiba emibini: enye kukugquma kumphezulu wephepha elaminethiweyo, kwaye enye kukubeka umaleko wekhadibhodi ekhuselayo enobunzima obuthile kwisitaki ngasinye ngexesha lenkqubo yokupakisha, ekwasebenza nayo. njengomjelo weoyile wokuchitha ubushushu.

Kwi-transformer yomthamo omkhulu, ukwenzela ukuba ubushushu obuveliswe kwi-iron core bunokuthi buthathwe yi-oyile ye-transformer kwi-circulation, kukho iipaseji zeoli zokupholisa kwikholamu yentsimbi kunye nejoka. Iipaseji ze-oyile zinokubethelwa ukusuka kwi-silicone sheet sheets ukuya kwiipleyiti ezinodaka okanye Iqukethe imivalo yentsimbi edityaniswe kumaphepha ensimbi ye-silicon. Kwimibhobho ye-transformer ene-oblique egcweleyo, ukwenzela ukunciphisa ilahleko, ii-slats zezinto ezingezona zetsimbi zisetyenziselwa ukwahlula iziteshi zeoli.

Ukugaywa kombindi wentsimbi:

Ngethuba lokusebenza kwe-transformer, ngenxa yezikhundla ezahlukeneyo zentsimbi yentsimbi kunye nezakhiwo zayo zetsimbi kwintsimi yombane, izinto ezinokuthi zenziwe zihluke. Xa umahluko onokwenzeka phakathi kwamanqaku amabini ufikelela kwixabiso elithile, kwenzeka into yokukhutshwa. Ngenxa yokukhutshwa, ioli ye-transformer iya kuchithwa okanye i-insulation eqinile iya konakala. Ukuze ugweme le nto, i-iron core kunye nezakhiwo zayo zentsimbi kufuneka zisekelwe ngokufanelekileyo.

Izixhobo zentsimbi ezingundoqo

Icandelo II. Ukujija kweTransformer

Umxholo oyintloko wecandelo le-transformer winding yi-wire kunye ne-winding method ye-transformer winding.

Ikhoyili yisekethe yombane yegalelo le-transformer kunye nokuphuma kwamandla ombane, kwaye iyona nxalenye esisiseko ye-transformer. Iikhoyili kufuneka ziyilwe ukuhlangabezana nezi mfuno zilandelayo:

1. Amandla ombane

Impembelelo yombane imelana nombane

Impembelelo yokusebenza imelana nombane

Amandla ombane axhathise amandla ombane

2. ukumelana nobushushu

Ngaphantsi kobushushu obuveliswa ngokusebenza kwexesha elide, ubomi benkonzo ye-insulation ye-coil akufanele ibe ngaphantsi kweminyaka engama-20.

Ngaphantsi kweemeko zokusebenza kwe-transformer, isiphaluka esifutshane ngokukhawuleza senzeke nakweyiphi na isiphelo somgca, kwaye i-coil kufuneka ikwazi ukumelana nokushisa okwenziwa ngumbane omfutshane ngaphandle komonakalo.

3. Amandla omatshini

uhlobo lwekhoyili;

Uhlobo lwekhoyili lukhethwa ikakhulu ngokuhambelana nomthamo wokuphumla njengombane wekhoyili, kwaye ikwaqwalasela amandla ombane, amandla oomatshini, ukutshatyalaliswa kobushushu kunye nokuba nokwenzeka kwenkqubo yokuvelisa. Ukukhethwa kwesakhiwo sekhoyili akukodwa, kwaye ngamanye amaxesha kukho iifom ezininzi zokukhetha. Oku kukwanxulumene nemikhwa yemveli yabavelisi abahlukeneyo be-transformer.

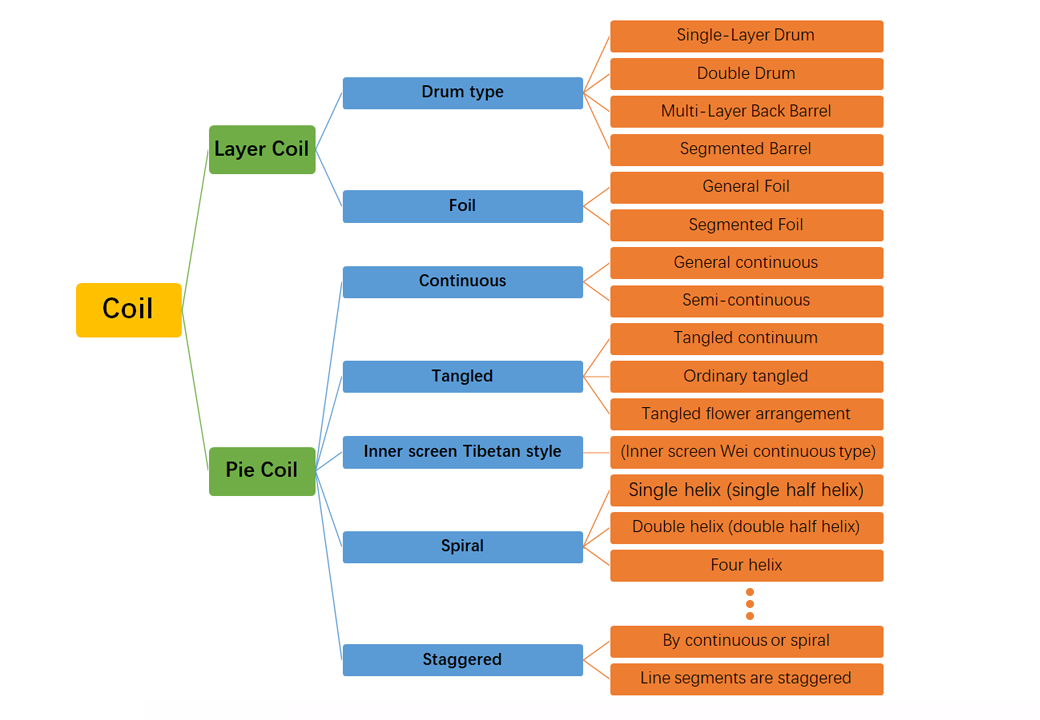

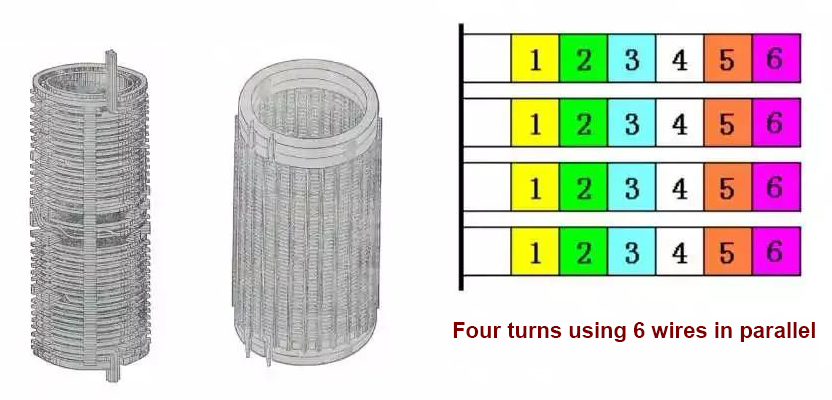

Iikhoyili zeTransformer zinokwahlulwa ngokufanelekileyo zibe ziindidi ezimbini: uhlobo lomaleko kunye nohlobo lwekhekhe. Iikhoyili zezikhonkwane zinokwahlulwa zibe zi-spiral, eziqhubekayo, ezibhijeneyo, ezibhijeneyo eziqhubekayo, ezikhuselweyo zangaphakathi eziqhubekayo kunye neentlobo zesakhiwo esigxadazayo.

I-Coil Wire:

Ucingo lomoya lunokwahlulwa lube lubhedu kunye ne-aluminiyam ngokwezixhobo ezahlukeneyo ze-conductor, ucingo olujikelezileyo kunye nocingo olusicaba ngokwemilo yomqhubi, iphepha, ipeyinti kunye nocingo lweglasi ngokwezinto zokugquma. Iziguquli zamandla zihlala zisebenzisa umtya wentsimbi osicaba ngephepha.

Iphepha eligqunywe ngocingo lwentsimbi olucaba lunokohlulwa lube lucingo oluqhelekileyo olugqunywe ngephepha, ucingo oludityanisiweyo, ucingo olugutyungelweyo kunye nezinye iintlobo. Ngokutsho kokuqina kocingo lwentsimbi, lunokwahlulwa lube lucingo oluqhelekileyo (00,≤120Mpa), ucingo lobhedu olunesiqingatha (120Mpa).<00.2≤210Mpa). Phakathi kwazo, kukho i-self-adhesive transposition wire kwi-transposition wire, oko kukuthi, ucingo olulodwa oluthe tye kwi-transposition wire luqatywe ngoluhlu lwe-epoxy resin (ubukhulu befilimu yepeyinti kumacala omabini.

0.06 ± 0.02mm), injongo kukunamathela zonke iingcingo ezincinci kunye emva kokuba ifilimu yepeyinti iphiliswe nge-thermal, ukwenzela ukuba kuphuculwe amandla e-short-circuit yekhoyili. Okwangoku, ucingo lokutshintshwa kwepakethe yamva nje lusetyenzisiwe, kwaye imigca yemveliso ehambelanayo iye yaziswa eTshayina.

Iingcingo zomoya zinokohlulwa zibe lubhedu kunye ne-aluminiyam ngokwemathiriyeli ye-conductor eyahlukeneyo, iingcingo ezingqukuva kunye neengcingo ezisicaba ngokwemilo yomqhubi, kunye nephepha, ipeyinti, kunye nocingo lweglasi ngokwemathiriyeli yokugquma. Iziguquli zamandla zihlala zisebenzisa ubhedu olusicaba olusongwe ngephepha. Umtya.

Ucingo lobhedu olugqunywe ngephepha lunokohlulwa lube lucingo oluqhelekileyo olugqunywe ngephepha, ucingo oludityanisiweyo, ucingo olugqithisiweyo kunye nezinye iintlobo. Ngokwamandla okuqina kocingo lobhedu, lunokwahlulwa lube lucingo oluqhelekileyo (02≤120Mpa), ucingo lobhedu oluqinileyo (120Mpa).<00, ≤210Mpa). Phakathi kwazo, kukho i-self-adhesive transposition wire kwi-transposition wire, oko kukuthi, ucingo olulodwa olusicaba kwi-transposition wire luqatywe ngoluhlu lwe-epoxy resin (ubukhulu befilimu yepeyinti kumacala omabini yi-0.06±0.02 mm), injongo kukutshisa ifilimu yepeyinti. Emva kokunyanga, gcina zonke iingcingo ezincinci kunye nokwandisa amandla ombane omfutshane wekhoyili. Okwangoku, ucingo lokutshintshwa kwepakethe yamva nje lusetyenzisiwe, kwaye imigca yemveliso ehambelanayo iye yaziswa eTshayina.

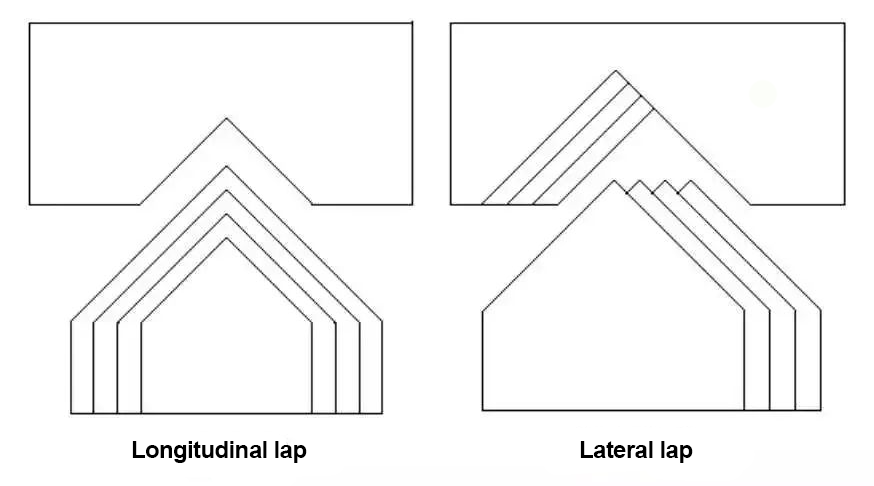

Ii-windings zihlala zohlulwe zibe ziindidi ezimbini: uhlobo lomaleko kunye nohlobo lwepayi.

Ukujika kojiko kucwangciswe kwaye kunxeba ngokuqhubekayo ecaleni kwe-axial direction, ebizwa ngokuba yi-layer winding. Umaleko ngamnye ufana ne-cylinder. Ukujika komphanda.

Ukujika kwe-winging kuqhutywe ngokuqhubekayo kwi-radial direction ukwenza i-pie (icandelo) imilo, kunye ne-winding eyakhiwe ngamabhiskithi amaninzi ahlelwe kwi-axial direction ibizwa ngokuba yi-pie winding. Kubandakanya i-capacitive windings eqhubekayo, edibeneyo kwaye ifakwe.

Iifom zokujija eziqhelekileyo:

Ii-winding eziqhelekileyo ziyi-cylindrical, i-spiral, i-continuous kunye ne-tangled.

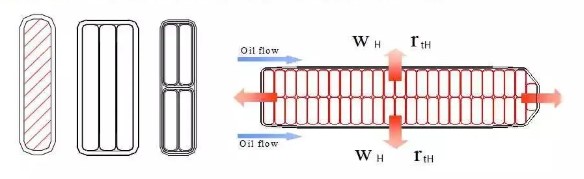

I-Cylindrical winding yolona hlobo lulula, kwaye ngokuqhelekileyo lwenziwe nge-winding enye okanye ezininzi. Xa ujija, ujija ujike omnye kufutshane necala lokungunda ngocingo, elifana nesetyhula elinxeba eliqinileyo lomthombo wekhoyili. Ibonakaliswe ngokujikeleza okulula, ukusebenza kakuhle, ukuchithwa kobushushu obuhle kwiipaseji zeoli phakathi kweengqimba, kodwa iindawo ezincinci zokuxhasa isiphelo kunye namandla angalunganga omatshini.

I-spiral winding yenziwe ngocingo oluthe tyaba, kwaye ukujika akusondeli omnye komnye, kodwa kuhlulwe ngumgama othile (ijelo le-oyile) kunye ne-insulating spacers, njengomthombo wekhoyili owoluliweyo. Inzuzo kukuba inkqubo yokucima ilula kwaye kukho umjelo weoli wokutshatyalaliswa kobushushu, kodwa ukujikeleza ngenani elikhulu lokujika akufanelekanga.

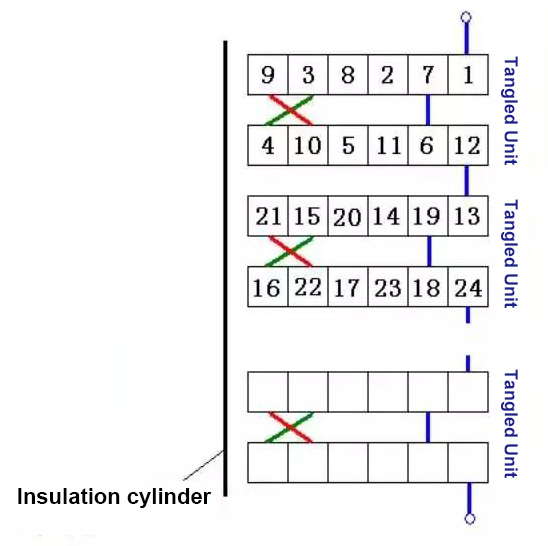

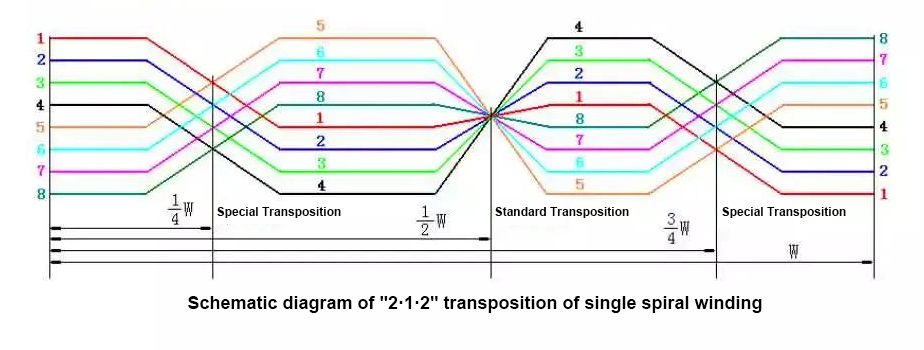

Uhlobo lwe-spiral lubandakanya iingcingo ezininzi ezilinxeba ngokunxuseneyo kwityhubhu yetayara eqinileyo, enokuthi ifakwe kuhlobo olulodwa lwe-helix, kwaye inokulimala ibe yi-double helix okanye uhlobo lwe-helix ezine xa kukho iingcingo ezinxuseneyo. Xa iingcingo ezininzi zidibaniswe ngokufanayo, iingcingo kufuneka zitshintshwe, ngaphandle koko kuya kubakho umbane ojikelezayo ngenxa yobude obungalinganiyo beentambo.

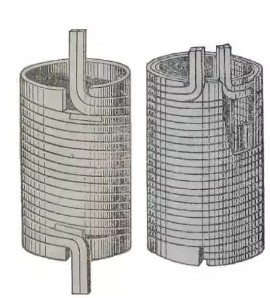

Ukujija okuqhubekayo kuqulunqwe yingcingo enye okanye ngaphezulu ethe tyaba ethe gqolo amanxeba amaninzi ibe ngamacandelo ocingo amile okwephayi kwi-cylinder yokugquma okanye iingcingo zokungunda ngocingo ngokusebenzisa inkqubo ekhethekileyo. Iingenelo zinamandla omatshini aphezulu kunye nokusebenza kakuhle kokutshatyalaliswa kobushushu. Kodwa inkqubo yokujija inzima ngakumbi.

Uxhulumaniso phakathi kwekhekhe locingo oluqhubekayo kunye nekhekhe locingo lutshintshile ngaphakathi nangaphandle kwe-winging, ngokokude ubude becingo buyanele, bunokuthi buyinxepheze kwi-winging eqhubekayo ngaphandle kwee-solder joints.

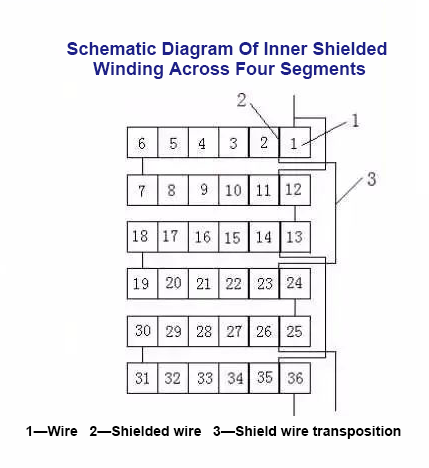

I-capacitive winding efakiweyo yenziwa ngokufaka ucingo (ucingo olukhuselekileyo) kunye ne-longitudinal capacitance phakathi kokujika ngaphakathi kwecala elingaphandle lekhekhe lentambo eqhubekayo. Ikhekhe locingo elifakiweyo kunye nenani leenguqu ezifakiweyo zingamiselwa ngokuhambelana nomthamo ofunekayo. Ucingo olukhuselweyo alunamsinga osebenzayo uyagqithiswa, ngoko ke iingcingo ezibhityileyo zidla ngokusetyenziswa.

I-capacitive winding efakiweyo ithatha ukujikeleza okuqhubekayo, okunokunciphisa inani elikhulu lamanqaku e-welding xa kuthelekiswa ne-tangled winding, kunye nenani lokujika kocingo olufakelweyo lokukhusela lunokulungelelaniswa ngokukhululekileyo, ukwenzela ukuba i-longitudinal capacitance inokulungelelaniswa njengoko kufuneka. Okwangoku, isetyenziswa kakhulu kwi-transformer windings ye-110kV nangaphezulu kwee-transformers ezinkulu.

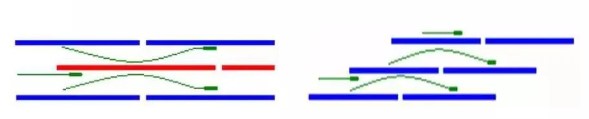

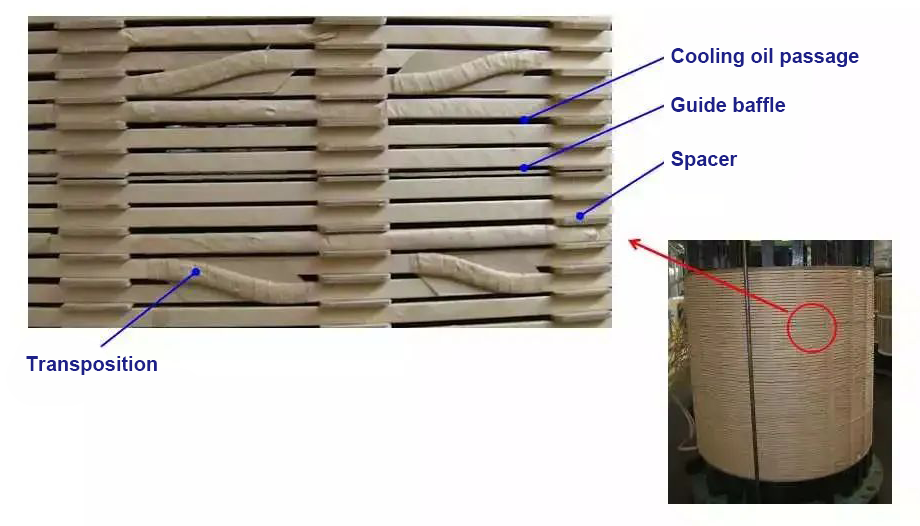

ukutshintshwa kocingo

Xa i-transformer yangoku inkulu, ukujika kwekhoyili kuqulunqwe ngeengcingo ezininzi ezihambelanayo. Ukuba akukho manyathelo athathiweyo, ucingo olusondeleyo kwi-axis ephakathi lufutshane, kwaye ucingo olude kwi-axis ephakathi lude. Ngenxa yobude obuhlukeneyo kunye nesikhundla socingo kwintsimi yamagnetic, ukuchasana kunye ne-inductive reactance yocingo ayilingani, kwaye ukusabalalisa kwangoku phakathi kwabaqhubi kubangelwa. engalungelelananga. Ukuze kuqinisekiswe ukuba i-current ihanjiswa ngokulinganayo kunye nokunciphisa ilahleko eyongezelelweyo, i-parallel conductors kufuneka itshintshe izikhundla, ezibizwa ngokuba yi "transposition".

QHAGAMSHELANA US

Thatha ithuba lolwazi lwethu kunye namava angenakuthelekiswa nanto, sikunika eyona nkonzo ilungileyo yokwenza ngokwezifiso.

i

i

SHIYA UMYALEZO

Nceda ugcwalise kwaye uthumele ifom engezantsi, siya kuqhagamshelana nawe kwiiyure ze-48, enkosi!

REIYAQHUBEKA

Zonke zenziwe ngokweyona migangatho ingqongqo yamazwe ngamazwe. Iimveliso zethu zifumene ubabalo kwiimarike zasekhaya nezangaphandle.