Izingxenye Eziyisisekelo Ze-A Transformer

1. Ukwakheka okuyisisekelo kwe-transformer

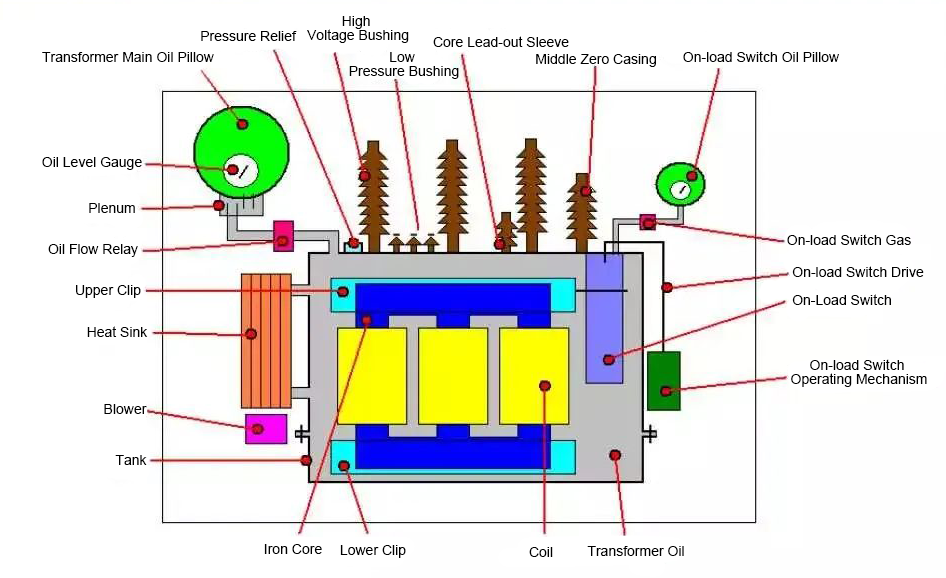

Ukwakhiwa okuyisisekelo kwama-transformer amakhulu ngokuvamile kuhlukaniswe izingxenye eziyi-7 ezilandelayo:

1.Ingxenye engumongo 1 ihlanganisa ikholomu, ijoka kanye nomshini wokubopha owenziwe ngokunqwabelanisa amashidi ensimbi ye-silicon.

I-2.Ingxenye yokuqala yokugoqa ihlanganisa izintambo eziholayo zesigaba ngasinye sokuphenduka kanye nokuxhumana kwayo

3.Ingxenye ye-insulation - kufaka phakathi uwoyela kanye nokufakwa kwephepha phakathi kwengxenye ngayinye neyakhe

I-4.Ingxenye ye-Fuel tank - ngaphezu kwe-fuel tank ngokwayo, ihlanganisa namathangi okugcina uphethiloli, amabakaki, njll.

5.Isistimu yokupholisa - kuhlanganise i-cooler noma i-radiator, iphampu kawoyela, ifeni, inqwaba, njll.

6.Amathuluzi okulinganisa - okuhlanganisa ama-thermometers esignali, ama-transformer amanje, ama-gauge ezingeni likawoyela, njll.

I-7.Amadivayisi okuvikela - ama-pressure releasers, ama-gas relays, ama-absorber umswakama, njll.

Phakathi kwazo, izingxenye ezimbili zokuqala nazo zingabizwa ngokuthi ingxenye yesifunda samagnetic kanye nengxenye yesifunda, okuyizingxenye eziyisisekelo.

Umdwebo we-Schematic wezingxenye eziyinhloko ze-transformer

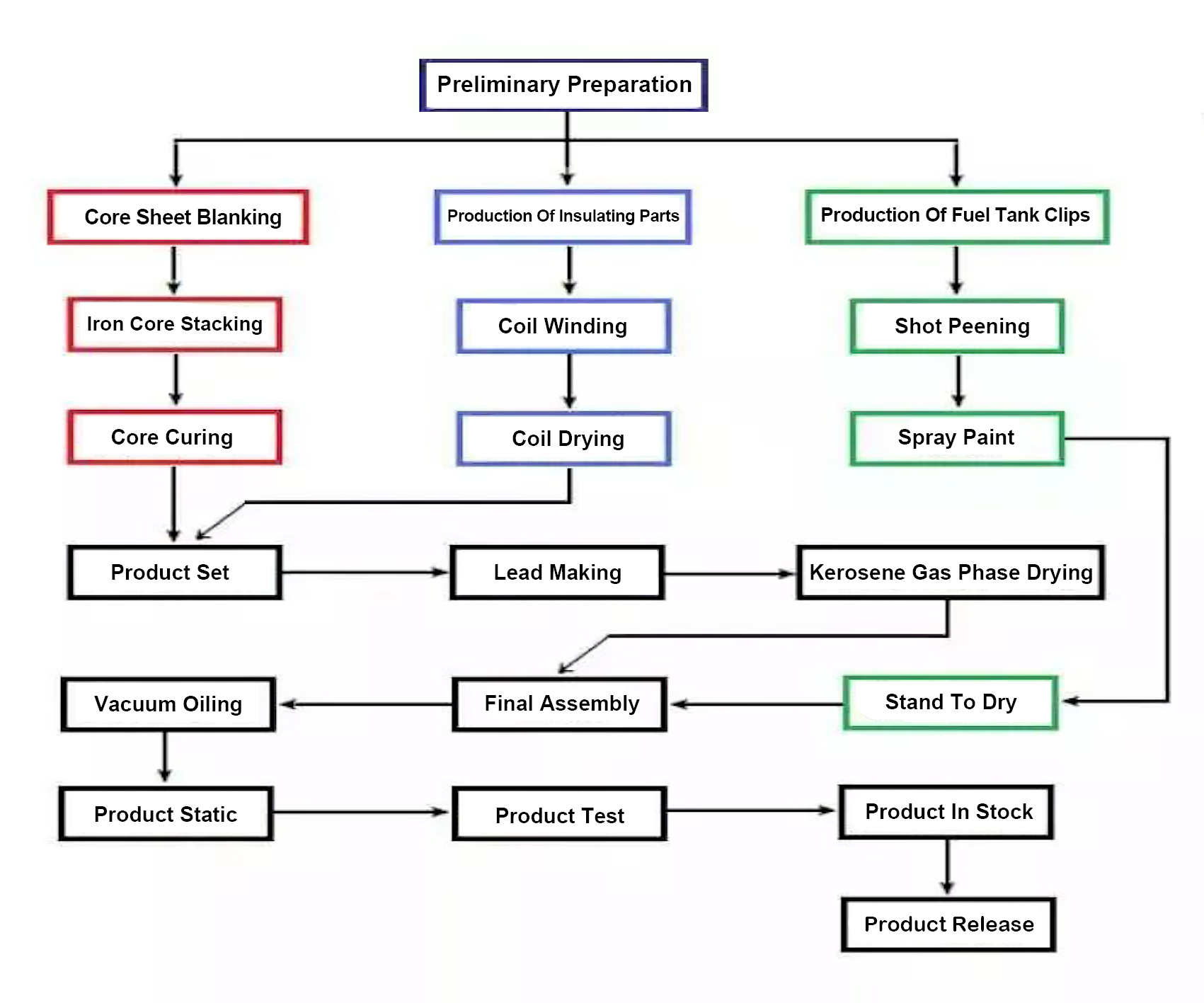

Inqubo Yokukhiqiza I-Transformer

Okuqukethwe okuyinhloko kokwethulwa kwe-transformer core ukusika, ukupakisha, ukulungiswa kwe-transformer core kanye nobuchwepheshe bamuva bokupakisha ukunciphisa ukulahlekelwa okungekho umthwalo.

2. Umongo we-Transformer

Umnyombo uyingxenye eyisisekelo ye-transformer. Iqukethe i-conductor kazibuthe kanye nedivaysi yokubopha. Inemisebenzi emibili: ngokuyisisekelo, i-conductor kazibuthe ye-iron core yisekethe kazibuthe ye-transformer, eguqula amandla kagesi wesekethe yokuqala ibe amandla kazibuthe, futhi isuka kumandla ayo kazibuthe iwayise emandleni kagesi wesekethe yesibili. , okuyindlela yokuguqula amandla. Ngokwesakhiwo, i-iron core isekela zonke izingxenye ezingaphakathi kwe-transformer, njengomzimba kanye nomkhondo.

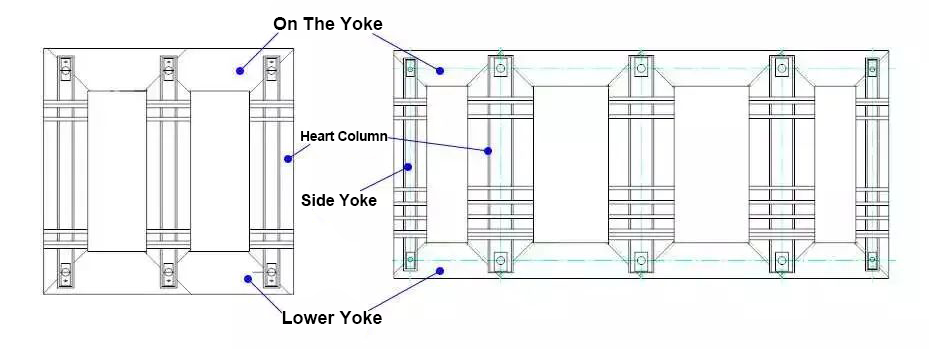

Umnyombo wensimbi we-transformer uyisakhiwo esivaliwe esimise okwefreyimu. Ingxenye yekhoyili ibizwa ngokuthi ikholomu ewumgogodla. Ingxenye engayimbozi ikhoyili futhi idlala indima yokuvala ukujikeleza kazibuthe ibizwa ngokuthi i- iron giant.

Izinhlobo zensimbi

Ngokuya ngokuhlobene nendawo yokusonteka kanye nensimbi, ingqikithi yensimbi ingahlukaniswa izigaba ezimbili: uhlobo oluyinhloko kanye nohlobo lwegobolondo. Insimbi yohlobo lwenhliziyo kuphela eyethulwa lapha okwamanje. Kwabaguquli besigaba esisodwa, ingqikithi yensimbi inamafomu amaningana esakhiwo, njengekholomu emibili kanye nekholomu emibili, ikholomu eyodwa-ikholomu emine, kanye nekholomu ephindwe kabili ikholomu emine.

Kuma-transformer ezigaba ezintathu, umgogodla wensimbi unamafomu amaningana esakhiwo njengekholomu emibili kanye nekholomu emibili (ikholomu yezigaba ezintathu-ikholomu), ikholomu emithathu kanye nekholomu emine (ikholomu yezigaba ezintathu). Ukukhethwa kwesakhiwo esiyinhloko kunqunywa ngokuya ngezinto ezibanzi ezifana nokuhlelwa okunengqondo kwama-winding ahlukahlukene, ukonga impahla, nokuhlangabezana nobude bezokuthutha. I-Bypass inganciphisa igagasi lesihlanu nelesikhombisa ku-flux yokuvuza kanye namandla kazibuthe.

Umucu wensimbi kagesi (ishidi lensimbi ye-silicon):

Izinto ezisetshenziselwa i-iron core conductor kazibuthe yi-electric steel strip enokuqukethwe okuphezulu kwe-silicon, eyaziwa nangokuthi ishidi le-silicon steel.

Kunezinhlobo ezimbili zamashidi ensimbi ye-silicon: ukugoqa okubandayo nokugoqeka okushisayo, lapho amashidi ensimbi e-silicon egoqiwe ahlukaniswe abe izinhlobo ezimbili: angaqondile futhi angaqondile-

Izici kazibuthe zamashidi ensimbi ye-silicon egoqwe ashisayo zimbi, ukuminyana kazibuthe kungafinyelela ku-1.5T kuphela, futhi ukulahlekelwa kweyunithi kukhulu kakhulu, ngakho akusasetshenziswa. Ishidi le-silicon yensimbi egoqelwe okusanhlamvu linendlela esobala, ukuminyana kukazibuthe okugcwala okuphezulu, ukulahleka kweyunithi encane namandla okuvusa amayunithi, futhi lisasetshenziswa kabanzi njengamanje.

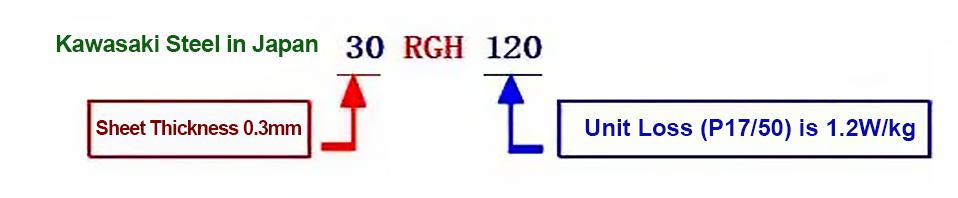

Ugqinsi lweshidi lensimbi eligoqelwe okusanhlamvu eligoqelwe ngokubanda linokucaciswa okuningana, okufana no-0.35mm, 0.3mm, 0.27mm, 0.23mm, njll. Elivame ukusetshenziswa ngu-0.3mm, futhi liya liba lincane ngokuba lincane, futhi inhloso enkulu ukunciphisa ukulahlekelwa okuphambene okungalayishiwe.

·Okwamanje, izindawo eziphambili ezikhiqiza amashidi ensimbi ye-silicon yi-Japan, Western Europe, Russia, South Korea kanye ne-Wuhan Iron and Steel yasekhaya.

Ukucaciswa kwamashidi ensimbi ye-silicon egoqelwe okusanhlamvu amelelwa ngokuyinhloko ukujiya nokulahlekelwa kweyunithi (W/kg) lapho ukuminyana kukazibuthe okungu-50Hz kungu-1.7T, isibonelo:

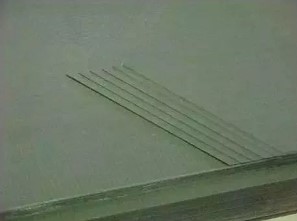

·Ishidi lensimbi elisanda kwakhiwa lisebenzisa i-laser irradiation kanye nobuchwepheshe bokuqoshwa komshini

Ukugunda kwe-transformer core silicon steel sheet:

Lapho impahla ye-silicon steel sheet ingena embonini, iyikhoyili enobubanzi obungaba ngu-1000mm. Idinga ukusikwa ibe yisimo esidingekayo ngemishini yokugunda okukhethekile (njengocingo lwaseJalimane lweGeorger). Ibhula yokugunda yeshidi ngalinye akufanele ibe ngaphezu kuka-0.02mm.

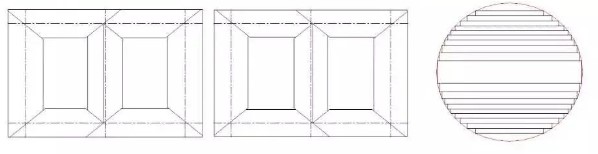

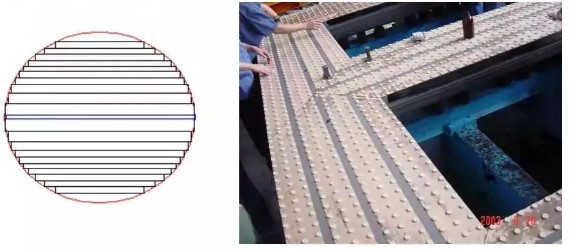

Ukupakishwa kwe-iron cores:

●Ngenxa yokuthi ikhoyili ye-core type transformer iyindilinga, ingxenye yekholomu ewumgogodla kufanele futhi ibe yindilinga, kodwa kunzima ukuyikhiqiza futhi ayinayo umnotho, ngakho yenziwa isiteji (uhlobo lwesilinda). Isinyathelo ngasinye sakha unxande, futhi umkhawulo wangaphandle utholakala kusiyingi esifanayo. Inombolo yezinyathelo inomkhawulo othize, okudingeka ucatshangelwe kabanzi ngokuya ngezinzuzo zomnotho.

●Lapho ama-iron cores enqwabelana, ikholomu ewumgogodla nezingcezu zensimbi zejoka lensimbi ziboshelwa ngokushintshana yisiqephu esisodwa noma ezimbalwa, ukuze amalunga ezinqenqema zezingxenye ezingaphezulu nezingaphansi zamashidi ensimbi ye-silicon anyakaze futhi amboze. ngabanye. Ukulahleka kwamanje nokungalayishi kuyancishiswa ngenkathi kuthuthukiswa amandla.

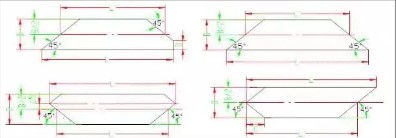

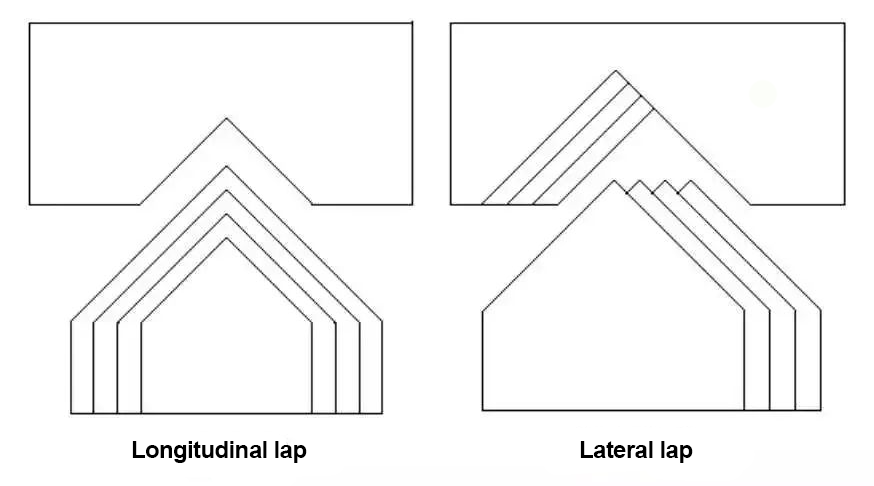

I-Lap joint of iron core piece:

·Okwamanje, i-transformer core ithatha uhlobo lwe-oblique joint egcwele, okungukuthi, ukuhlangana kwekholomu ewumgogodla kanye nejoka lensimbi ngu-45 °. Leli fomu elihlanganyelwe lizifanele ngokuphelele izici zeshidi lensimbi le-silicon eligxile kukazibuthe elivame ukusetshenziswa njengamanje. Yenza ukujikeleza kazibuthe kuhambisane ngangokunokwenzeka.

·Kuma-transformer cores amakhulu anamajoyini agcwele ama-miter, ukupakishwa ngokuvamile kwenziwa ngendlela yamajoyinti anezigaba ezimbili. Ukuze kuthuthukiswe kangcono izici ezingenamthwalo we-transformer core, kwakhiwa ifomu le-multilevel seam ye-core, okungukuthi, i-StepLap core.

Emkhakheni we-laminated, ama-seams amashidi ensimbi ye-silicon ayanyakaziswa. Lapho ukuguquguquka kukazibuthe kocezu oluthile kuhlangana negebe lomoya emthungoni, amandla kazibuthe egebe lomoya aphindwe izikhathi eziyizinkulungwane ezimbalwa kuneshidi lensimbi ye-silicon. Iningi le-flux lidlula kumashidi ensimbi e-silicon aseduze ahlanganisa leli lungu. Ukuguquguquka kazibuthe kwangempela kwama-laminations emalungeni amabhuloho kanye nokuguquguquka kazibuthe okuvala ibhuloho kubekwe phezulu. Ukuminyana kungase kufinyelele ukugcwala, ukuze ukulahlekelwa okungenamthwalo kanye nokungabikho komthwalo wamanje endaweni ehlangene (okungukuthi, indawo) kukhuphuke kakhulu, ukuze ukulahlekelwa okuphelele okungekho umthwalo kukhule.

I-Step Lap ubuchwepheshe obusha be-lamination obusetshenziswe kulo nyaka, obungathuthukisa ukuminyana kazibuthe kweshidi lensimbi ye-silicon endaweni ehlangene, ngaleyo ndlela kunciphise ngempumelelo ukulahlekelwa okungekho mthwalo nomsindo wengxenye ewumgogodla.

I-Core insulation:

I-insulation ye-iron core inomthelela oqondile kwikhwalithi yomkhiqizo we-transformer core. I-insulation ye-iron core ingahlukaniswa izingxenye ezimbili: ukufakwa phakathi kwamashidi kanye nokufakwa phakathi kwama-laminations kanye nezingxenye zesakhiwo.

I-inter-chip insulation ngokuyinhloko ifinyelelwa ngezici ezimbili: enye iwukumboza phezu kweshidi elamiwe, kanti enye iwukubeka ungqimba lwekhadibhodi elivikelayo elinogqinsi oluthile esitaki ngasinye ngesikhathi senqubo yokunqwabelanisa, ebuye isebenze. njengomzila wamafutha wokukhipha ukushisa.

Ku-transformer enkulu-umthamo, ukuze wenze ukushisa okukhiqizwa ku-iron core kungasuswa ngamafutha e-transformer ekujikelezeni, kukhona amavesi okupholisa amafutha kukholomu yensimbi kanye nejoka. Amaphaseji kawoyela angashaywa asuka ku-silicon steel sheets abe amapuleti kathayela noma Aqukethe izinsimbi zensimbi ezishiselwe kumashidi ensimbi ye-silicon. Kuma-cores e-transformer anamajoyini agcwele ama-oblique, ukuze kuncishiswe ukulahlekelwa, ama-slats angewona ama-metallic asetshenziselwa ukuhlukanisa iziteshi zamafutha.

Ukugaywa kwe-iron core:

Ngesikhathi sokusebenza kwe-transformer, ngenxa yezikhundla ezihlukene zensimbi kanye nezakhiwo zayo zensimbi emkhakheni kagesi, amandla akhiqizwayo nawo ahlukile. Uma umehluko ongaba khona phakathi kwamaphoyinti amabili ufinyelela inani elithile, kwenzeka into yokukhishwa. Njengomphumela wokukhishwa, amafutha e-transformer azochithwa noma ukufakwa okuqinile kuzolimala. Ukuze ugweme lesi simo, umgogodla wensimbi kanye nezingxenye zawo zesakhiwo sensimbi kufanele kusekelwe ngokuphumelelayo.

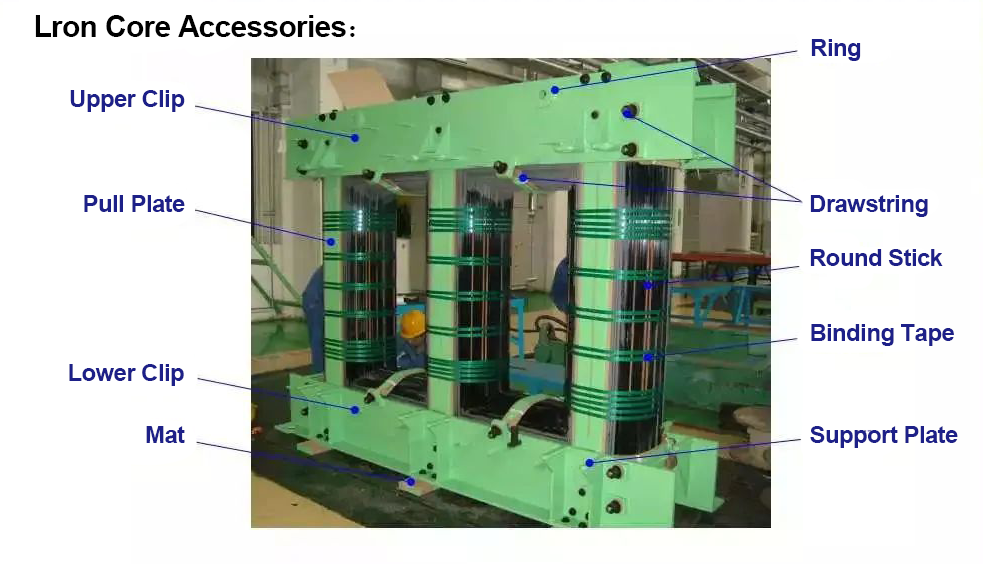

Izesekeli ze-Iron Core

Ingxenye II. Ukuguqulwa kwe-Transformer

Okuqukethwe okuyinhloko kwengxenye yokuguqula i-transformer yindlela yocingo kanye ne-winding ye-transformer winding.

Ikhoyili iyisekhethi kagesi yamandla kagesi okufakwayo nokuphumayo kwe-transformer, futhi iyisakhi esiyisisekelo se-transformer. Amakhoyili kufanele aklanywe ukuze ahlangabezane nezidingo eziyisisekelo ezilandelayo:

1. Amandla kagesi

Umbani umelane ne-voltage

Umfutho osebenzayo umelana ne-voltage

Imvamisa yamandla imelana ne-voltage

2. ukumelana nokushisa

Ngaphansi kokushisa okukhiqizwa ukusebenza kwamanje isikhathi eside, impilo yesevisi ye-insulation yekhoyili akufanele ibe ngaphansi kweminyaka engu-20.

Ngaphansi kwezimo zokusebenza ze-transformer, isifunda esifushane esingazelelwe senzeke kunoma yikuphi ukuphela komugqa, futhi ikhoyili kufanele ikwazi ukumelana nokushisa okukhiqizwa umjikelezo omfushane wamanje ngaphandle kokulimala.

3. Amandla omshini

uhlobo lwekhoyili;

Uhlobo lwekhoyili lukhethwa ngokuyinhloko ngokuvumelana nomthamo wokuphumuza njenge-voltage yekhoyili, futhi kucabangela amandla kagesi, amandla emishini, ukunqanyulwa kokushisa kanye nokwenzeka kwenqubo yokukhiqiza. Ukukhethwa kwesakhiwo sekhoyili akuhlukile, futhi ngezinye izikhathi kunezinhlobo eziningana zesakhiwo ongakhetha kuzo. Lokhu futhi kuhlobene nemikhuba yendabuko yabakhiqizi abahlukahlukene be-transformer.

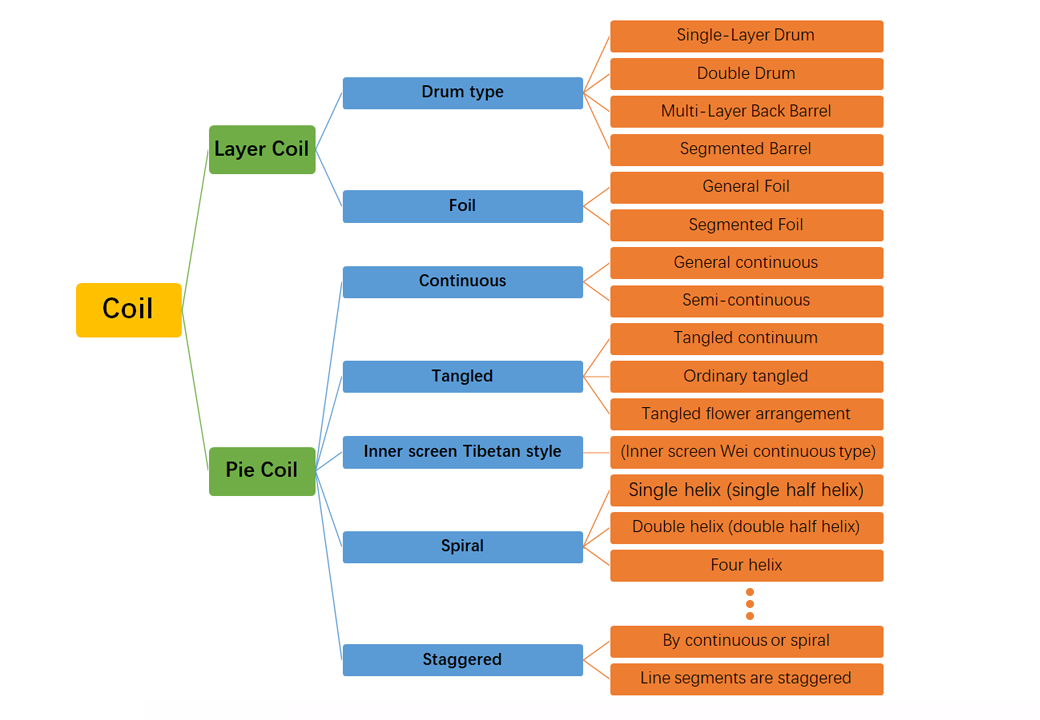

Amakhoyili e-Transformer angahlukaniswa cishe abe yizinhlobo ezimbili: uhlobo lwe-layer kanye nohlobo lwekhekhe. Amakhoyili ephinikhodi angahlukaniswa abe yizinhlobo ezisathandeka, eziqhubekayo, eziphithene, ezigoqeneyo eziqhubekayo, ezinezivikelo zangaphakathi eziqhubekayo kanye nezinhlobo zesakhiwo esimangelengele.

Intambo yekhoyili:

I-Winding wire ingahlukaniswa ibe yithusi ne-aluminium ngokusho kwezinto ezihlukene zomqhubi, ucingo oluyindilinga nocingo oluyisicaba ngokuya ngokuma komqhubi, iphepha, upende kanye nocingo lwengilazi ngokuya ngezinto zokuvikela. Ama-transformer kagesi ngokuvamile asebenzisa iString steel flat esongwe ngephepha.

Intambo yensimbi eyisicaba embozwe ngephepha ingahlukaniswa ngocingo oluvamile olumbozwe ngephepha, intambo ehlanganisiwe, intambo eguquliwe kanye nezinye izinhlobo. Ngokusho kokuqina kocingo lwensimbi, ingahlukaniswa ngocingo olujwayelekile (00,≤120Mpa), ucingo lwethusi oluqinile (120Mpa<00.2≤210Mpa). Phakathi kwazo, kukhona ne-self-adhesive transposition wire ku-transposition wire, okungukuthi, ucingo olulodwa oluyisicaba ocingweni lokuguqula lumbozwe ungqimba lwe-epoxy resin (ubukhulu befilimu kapende nhlangothi zombili.

0.06 ± 0.02mm), inhloso iwukunamathisela zonke izintambo ezincane ndawonye ngemva kokuba ifilimu kapende ilaphelwe ngokushisa, ukuze kuthuthukiswe amandla esiyingi esifushane sekhoyili. Njengamanje, kusetshenziswe intambo yakamuva ye-net package transposition, futhi imigqa yokukhiqiza ehambisanayo yethuliwe e-China.

Izintambo ezisongayo zingahlukaniswa zibe yithusi ne-aluminium ngokuvumelana nezinto ezihlukene zokuqhuba, izintambo eziyindilinga nezintambo eziyisicaba ngokuya ngokuma komqhubi, kanye nephepha, upende, nocingo lwengilazi ngokuya ngezinto zokuvikela. Ama-Power transformer ngokuvamile asebenzisa ithusi eliyisicaba eligoqwe ngephepha. Intambo.

Intambo yethusi eyisicaba embozwe ngephepha ingahlukaniswa ngocingo oluvamile olumbozwe ngephepha, intambo ehlanganisiwe, intambo eguquliwe kanye nezinye izinhlobo. Ngokusho kwamandla okuqina ocingo lwethusi, ingahlukaniswa ngocingo olujwayelekile (02≤120Mpa), ucingo lwethusi oluqinile (120Mpa<00, ≤210Mpa). Phakathi kwazo, kukhona futhi i-self-adhesive transposition wire ocingweni lokuguqula, okungukuthi, ucingo olulodwa oluyisicaba ocingweni lokuguqula lumbozwe ungqimba lwe-epoxy resin (ubukhulu befilimu kapende ezinhlangothini zombili buyi-0.06±0.02 mm), inhloso ukushisa ifilimu kapende. Ngemva kokwelapha, namathisela zonke izintambo ezincane ndawonye ukuze ukwandise amandla okujikeleza okufushane kwekhoyili. Njengamanje, kusetshenziswe intambo yakamuva ye-net package transposition, futhi imigqa yokukhiqiza ehambisanayo yethuliwe e-China.

Ama-windings ngokuvamile ahlukaniswe abe izinhlobo ezimbili: uhlobo lwesendlalelo nohlobo lwephayi.

Ukuphenduka kwamajika kuyahlelwa futhi kulinyazwe ngokuqhubekayo eduze kwe-axial direction, ebizwa ngokuthi i-layed winding. Ungqimba ngalunye lufana nesilinda. Ukujika komgqomo.

Ukuphenduka kokusonta kuhlale kulinyazwa ohlangothini lwe-radial ukuze kwakheke umumo wephayi (ingxenye), futhi ukujikajika okuhlanganiswe namabhisikidi amaningi ahlelwe ngendlela ye-axial kubizwa ngokuthi i-pie winding. Kubandakanya ama-capacitive windings aqhubekayo, aphithene futhi afakiwe.

Amafomu okugoqa ajwayelekile:

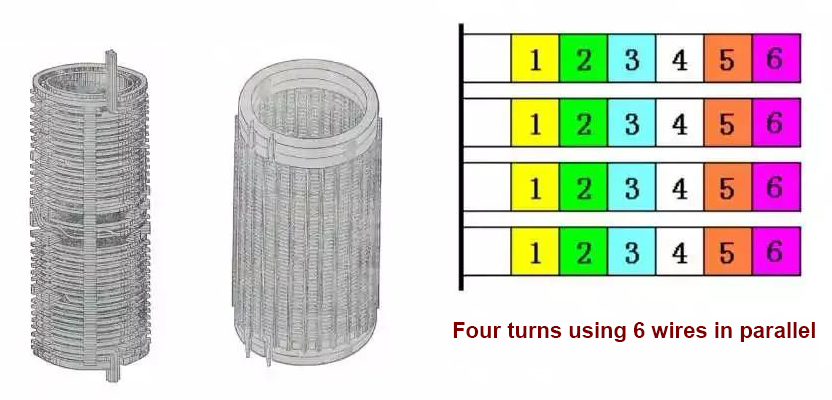

Ama-windings ajwayelekile ayi-cylindrical, i-spiral, i-continuous and tangled.

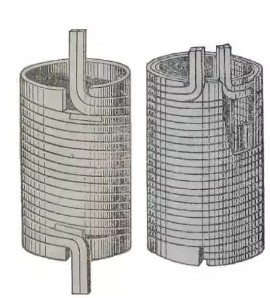

I-Cylindrical winding iwuhlobo olulula kakhulu, futhi ngokuvamile lwenziwa nge-winding eyodwa noma eziningana. Uma isongwa, iyalinyazwa ijika elilodwa eduze ne-axis yesikhunta socingo, efana nesisekelo sekhoyili esinenxeba eliyisiyingi. Ibonakala ngokusonteka okulula, umsebenzi omuhle, ukuchithwa kahle kokushisa kwamaphaseji kawoyela phakathi kwezingqimba, kodwa izindawo ezincane zokusekela ukuphela namandla angenamandla emishini.

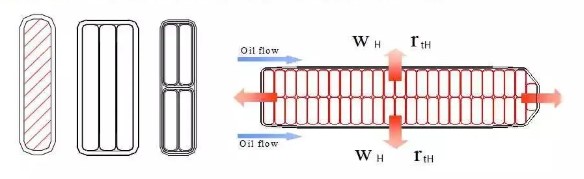

I-spiral winding yenziwe ngocingo oluyisicaba, futhi ukuphenduka akusondeli komunye nomunye, kodwa kuhlukaniswa ibanga elithile (isiteshi samafutha) esinama-spacers avikelayo, njengomthombo wekhoyili oweluliwe. Inzuzo yukuthi inqubo yokugubha ilula futhi kukhona isiteshi samafutha okushisa ukushisa, kodwa ukugoqa ngenani elikhulu lokujika akufanelekile.

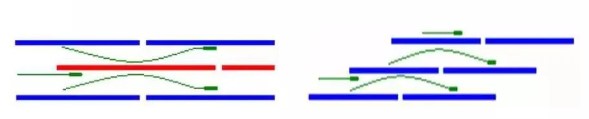

Uhlobo oluzungezayo luqukethe izintambo eziningi ezilinyazwe ngokuhambisana epayipini lethayi eliqinile, elingase lilimale libe uhlobo olulodwa lwe-helix, futhi lingahlanganiswa libe i-double helix noma uhlobo lwe-helix ezine uma kunezintambo eziningi ezihambisanayo. Uma izintambo eziningi zixhunywe ngokuhambisana, izintambo kufanele zidluliselwe, ngaphandle kwalokho kuyoba khona umjikelezo ojikelezayo ngenxa yobude obungalingani bezintambo.

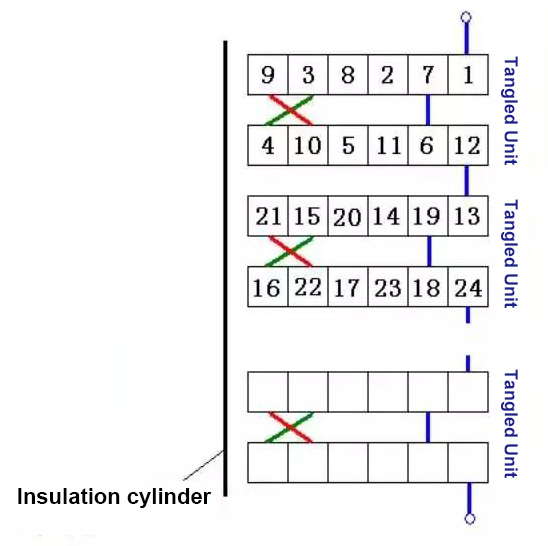

Ukusonteka okuqhubekayo kwenziwa ngezintambo eziyisicaba eyodwa noma eziningi ezihlale zilinyazwa ebuningini bezingxenye zocingo ezimise okwephayi kusilinda esivikelayo noma izintambo zesikhunta sezintambo ngenqubo ekhethekile. Izinzuzo zingamandla aphezulu wemishini kanye nokusebenza okuhle kokukhipha ukushisa. Kodwa inqubo yokusonta iyinkimbinkimbi kakhulu.

Ukuxhumana phakathi kwekhekhe locingo eliqhubekayo kanye nekhekhe locingo ngokushintshana ngaphakathi nangaphandle kwe-winding, inqobo nje uma ubude bocingo banele, bungakwazi ukulinyazwa ngokuqhubekayo ngaphandle kokuhlanganisa ama-solder.

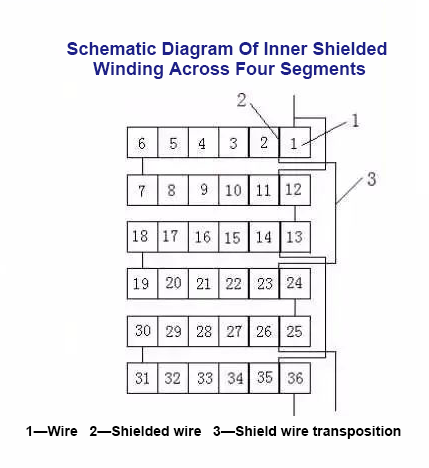

I-capacitive winding efakiwe yenziwa ngokufaka ucingo (intambo evikelekile) enomthamo we-longitudinal phakathi kokujika ngaphakathi kohlangothi olungaphandle lwekhekhe lezintambo ezisongayo. Ikhekhe locingo elifakiwe kanye nenani lokujika elifakiwe linganqunywa ngokuya ngekhono elidingekayo. Intambo evikelekile ayinalo I-current esebenzayo idlula, ngakho-ke izintambo ezincane kakhulu zivame ukusetshenziswa.

I-capacitive winding efakiwe ithatha ukuvunguza okuqhubekayo, okunganciphisa inani elikhulu lamaphoyinti wokushisela uma kuqhathaniswa nokuvunguza okuphithizelayo, futhi inani lokuphenduka kwentambo yokuzivikela efakiwe ingalungiswa ngokukhululekile, ukuze i-longitudinal capacitance ingalungiswa njengoba kudingeka. Njengamanje, isetshenziswa kakhulu kuma-transformer windings angu-110kV nangaphezulu kwama-transformer amakhulu.

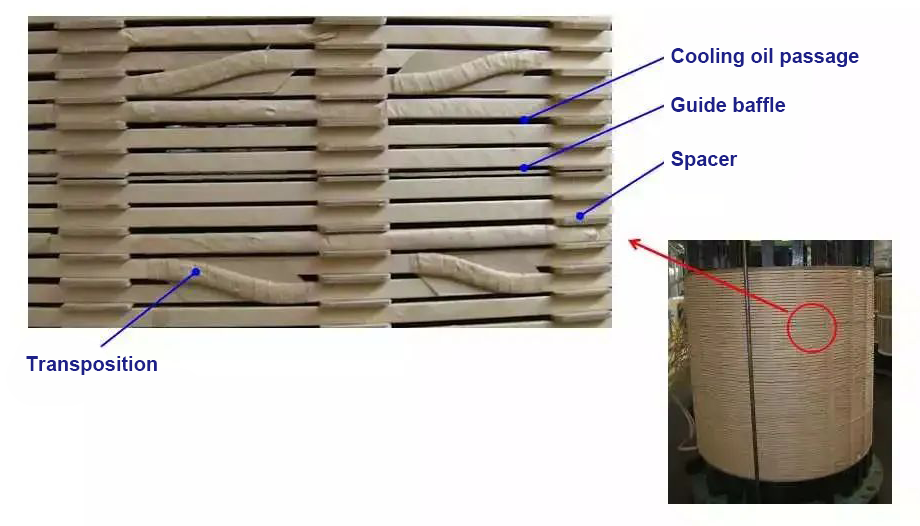

ukuguqulwa kwentambo

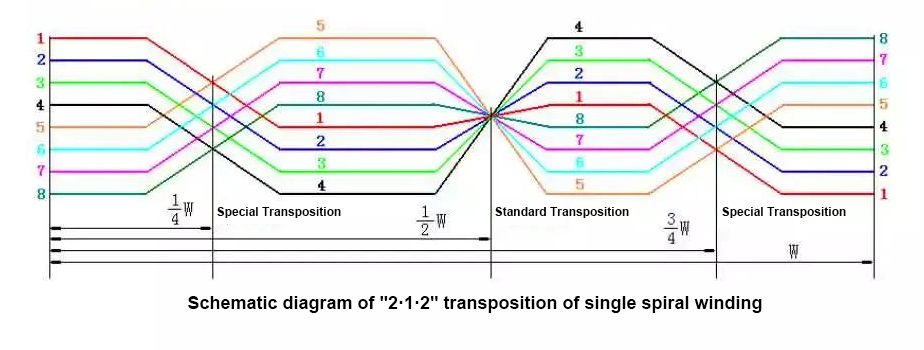

Lapho i-transformer yamanje inkulu, ukuphenduka kwekhoyili kwenziwa ngezintambo eziningi ezihambisanayo. Uma kungekho zinyathelo ezithathwayo, ucingo oluseduze ne-axis emaphakathi lufushane, futhi ucingo olukude ne-axis emaphakathi lude. Ngenxa yobude obuhlukene kanye nokuma kocingo endaweni kazibuthe, ukumelana nokusabela kwe-inductive kocingo akulingani, futhi ukusatshalaliswa kwamanje phakathi kwama-conductor kubangelwa. engalingani. Ukuze kuqinisekiswe ukuthi i-current isakazwa ngokulinganayo kuma-conductor futhi inciphise ukulahlekelwa okwengeziwe, ama-conductor afanayo kufanele ashintshwe izikhundla, okubizwa ngokuthi "ukuguqulwa".

CONTACT E-US

Thatha ithuba lolwazi lwethu nolwazi olungenakuqhathaniswa, sikunikeza isevisi engcono kakhulu yokwenza ngokwezifiso.

.

.

SHIYA UMLAYEZO

Sicela ugcwalise futhi uthumele ifomu elingezansi, sizokuthinta emahoreni angama-48, ngiyabonga!

REKUNCONYWA

Wonke akhiqizwa ngokuvumelana nezindinganiso zamazwe ngamazwe eziqinile. Imikhiqizo yethu ithole umusa kuzo zombili izimakethe zasekhaya nezangaphandle.