Uncover the essentials of transformer cores and understand the important factors to consider when making your selection for optimal performance.

Transformers stand as quiet sentinels in the realm of electrical systems, orchestrating the vital transfer and transformation of electrical energy that powers our modern world. These unassuming devices, often tucked away within substations or nestled within electronic equipment, form the backbone of electrical engineering, enabling the efficient distribution and utilization of electricity. Their role is fundamental, bridging the gap between power generation and practical consumption by stepping up voltage for long-distance transmission and stepping it down for safe use in our homes, industries, and devices. In essence, transformers are the uncelebrated architects of the electrified world we inhabit.

Beneath the unpretentious surface of transformers lies a critical component—the transformer core. This unassuming core, far from passive, serves as the very engine that drives the conversion of electrical energy into magnetic energy and back into electrical energy while minimizing energy losses. It is the linchpin of transformer functionality, governing not only efficiency but also reliability. The selection of the right transformer core is paramount, as it directly shapes efficiency, longevity, and electromagnetic characteristics. In this article, we embark on a journey to unveil the profound significance of transformers and, most notably, their indispensable cores, equipping you with the knowledge necessary to make well-informed choices for the optimal performance of electrical systems.

Key Considerations in Selecting a Transformer Core

Selecting the right transformer core involves a careful evaluation of several crucial factors. These considerations are essential to ensure that your choice aligns with the specific needs and constraints of your electrical application:

A. Material Type

1. Different Materials Used in Transformer Cores: Transformer cores are crafted from various materials, including iron, silicon steel, ferrite, and amorphous alloys. Each material exhibits distinct magnetic properties and characteristics that influence core performance.

2. How Material Type Affects Transformer Efficiency and Lifespan: The choice of core material significantly impacts transformer efficiency and longevity. Some materials, like silicon steel, offer high magnetic permeability, reducing core losses and enhancing efficiency. Understanding how material properties align with your application's requirements is essential for optimal transformer performance.

B. Core Shape and Design

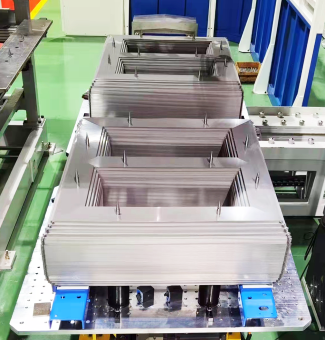

1. Common Designs of Transformer Cores (e.g., Toroidal, Shell, etc.): Transformers come in different shapes and designs, such as toroidal, shell, and C-core configurations. Each design offers specific advantages and limitations, influencing factors like size, weight, and electromagnetic interference.

2. How Core Shape Impacts Transformer Function and Effectiveness: The shape and design of the transformer core have a direct impact on its functionality and effectiveness. Toroidal cores, for example, provide compact and efficient designs with minimal electromagnetic interference, making them suitable for specific applications. Understanding the interplay between core shape and performance is vital for making the right choice.

C. Size and Dimension Requirements

1. The Role of Size and Dimension in Transformer Core Selection: The physical size and dimensions of the core are critical considerations. These parameters must align with the available space and form factor constraints within your application.

2. Matching Core Size to Your Specific Application Needs: Ensuring that the selected core size matches your application's requirements is crucial. A well-fitted core enhances efficiency and minimizes electromagnetic interference.

D. Cost and Budget Constraints

1. Cost Variations Among Different Transformer Core types and Materials: Transformer cores vary in cost depending on the material and type chosen. Factors like core material cost and manufacturing complexity contribute to price differences.

2. Aligning Your Core Selection with Budgetary Constraints: To make an economically viable choice, it's important to consider your budgetary constraints and explore core options that strike a balance between cost and performance. This aligns your core selection with your financial parameters while optimizing your electrical system's efficiency.

Carefully evaluating these key considerations ensures that your power transformer core choice aligns seamlessly with your application's unique needs and constraints, leading to enhanced performance, efficiency, and cost-effectiveness.

Making the Right Choice: A Step-by-Step Guide

Choosing the ideal transformer core demands a systematic approach that takes into account your specific requirements and the critical factors that govern core selection. This step-by-step guide will lead you through the process, ensuring that your choice aligns perfectly with your application:

Assessing Your Specific Needs and Application Requirements

1. Understanding Your Requirements: Begin by comprehensively assessing your application's electrical needs. This includes determining the required voltage, power capacity, and frequency range that the transformer must operate within.

2. Environmental Considerations: Factor in environmental conditions, such as temperature, humidity, and electromagnetic interference, which can impact core performance.

3. Consulting Experts: Don't hesitate to seek guidance from experts or engineers specialized in transformer design, as their insights can be invaluable in ensuring a precise fit for your application.

Evaluating Different Options Based on Key Considerations

1. Selecting Core Material: Based on your application's frequency and efficiency requirements, choose the appropriate core material, considering properties like magnetic saturation and core losses.

2. Assessing Core Shape and Design: Evaluate the available space and electromagnetic interference constraints within your application. Choose a core type that accommodates these limitations while ensuring optimal performance.

3. Sizing and Dimensioning: Calculate the core's physical dimensions based on your specific turns ratio and core material properties. Ensure that the selected core size can accommodate the required number of windings and provide the necessary magnetic flux.

4. Budget Alignment: Explore the cost variations among different transformer core types and materials. Align your core selection with budgetary constraints, considering long-term return on investment (ROI) and total cost of ownership (TCO).

Making a Final Decision and Future-Proofing Your Choice

1. Validation through Testing: Once the transformer is constructed, conduct comprehensive testing to validate its performance against initial requirements. Measure parameters like efficiency, voltage regulation, and frequency response to ensure they meet or exceed expectations.

2. Iterative Refinement: If necessary, refine your core selection and design based on test results and real-world performance. Be open to making adjustments to enhance efficiency and reliability.

3. Future-Proofing: Consider future scalability and technology advancements that may affect your core choice. Design your transformer for adaptability, enabling easy modifications or upgrades to meet evolving needs.

4. Documentation and Knowledge Transfer: Ensure that the knowledge gained during the core selection process is well-documented and transferred to relevant team members or successors to maintain consistency and efficiency in future projects.

By meticulously following this step-by-step guide, you can navigate the complexities of transformer core selection with confidence, ensuring that your choice aligns precisely with your application's unique requirements and future-proofing your electrical system for long-term success.

Avoiding Common Pitfalls in Transformer Core Selection

Selecting the right transformer core can be a nuanced endeavor, and steering clear of common pitfalls is crucial to achieving optimal performance. Here are key mistakes to avoid:

Overlooking the Importance of Core Material

One of the most prevalent mistakes in transformer core selection is underestimating the significance of core material. Neglecting the suitability of the chosen material for your application's needs can lead to suboptimal performance. Avoid this by:

●Conducting thorough research on core materials and their properties.

●Considering factors like magnetic saturation, permeability, and core losses when evaluating materials.

●Recognizing that the core material directly influences transformer efficiency and longevity.

●Consulting with experts or engineers to make an informed decision on material selection.

Neglecting Size and Dimension Requirements

The physical size and dimensions of the transformer core are critical, and overlooking these aspects can result in core mismatch and inefficiency. Prevent this pitfall by:

●Carefully assessing your application's space constraints and form factor limitations.

●Calculating the core size precisely based on your specific requirements, including turns ratio and core material properties.

●Ensuring that the selected core size aligns with your application's available space while maintaining optimal performance.

Not Considering Long-Term Cost-Effectiveness

Focusing solely on immediate costs without considering long-term cost-effectiveness is a common mistake. Overspending on premium core materials or types that exceed your application's requirements can strain your budget unnecessarily. Avoid this error by:

●Conducting a cost-benefit analysis to strike a balance between core costs and energy savings.

●Exploring alternative core materials or transformer core types that meet your requirements at a lower cost without sacrificing performance.

●Considering the long-term return on investment (ROI) and total cost of ownership (TCO) when making core selections.

By evading these common pitfalls and embracing a holistic approach to core selection, you can make well-informed decisions that lead to efficient, cost-effective, and reliable electrical systems.

Conclusion:

In summary, the process of selecting the right transformer core is a multifaceted journey that begins with understanding your application's unique needs and constraints. It encompasses material selection, core design considerations, size, and cost-effectiveness. Rigorous testing and future-proofing your choice ensure long-term success. The importance of making an informed and well-considered core selection cannot be overstated. Your choice is not just a technical decision but a strategic one that underpins the efficiency and reliability of your electrical system. With diligence and expertise, you are well-prepared to embark on this journey confidently, empowering your system to thrive in the ever-evolving landscape of energy distribution and utilization.