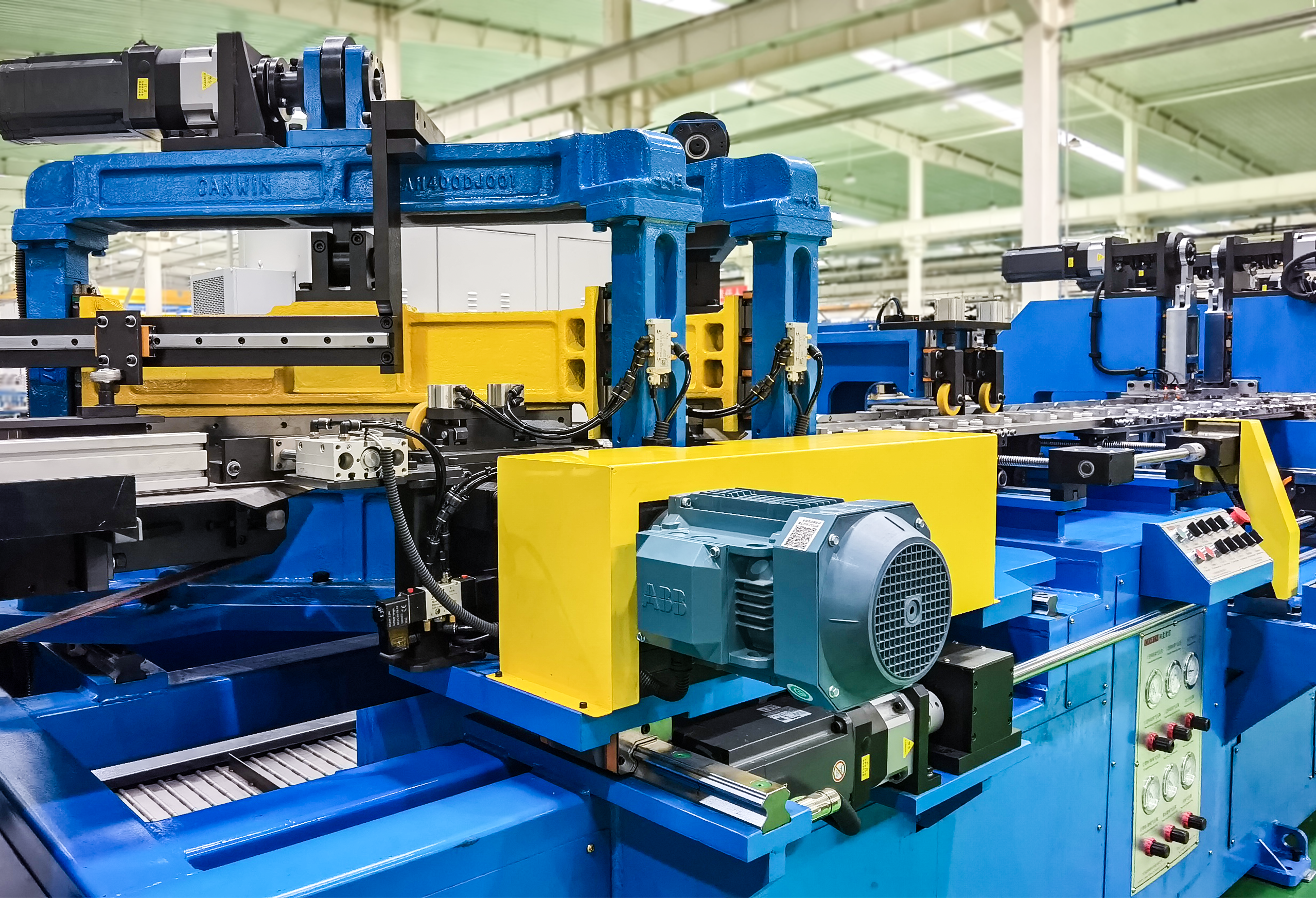

CANWIN CK High-Speed Cut To Length Line (Model:CAH(223) - 400CK)

CANWIN CK high-Speed Cut To Length Line (model: CAH (223) -400CK) is a high-precision and high-efficiency solution designed specifically for transformer core processing. It integrates advanced automation technology, modular design, and high-speed performance to meet the needs of transformer core material processing, forming, and precision machining.

At the heart of the CAH(223) - 400CK lies a robust centralized positioning system, which synchronizes multiple processing units to achieve flawless coordination. The line is equipped with dual unrolling mechanisms, ensuring continuous material feeding while maintaining tension control for optimal stability. This configuration enables simultaneous cutting operations across various stages, drastically reducing cycle times and boosting throughput without sacrificing accuracy.

The shearing line features dual oblique-angle cutting shear machines and high-performance punch presses, driven by precision servo motor controls. These servo systems enable dynamic adjustments in forward, backward, lateral, and diagonal directions, allowing the machine to adapt to diverse material thicknesses and shapes. The inclusion of V-shaped punch and shear modules further enhances versatility, enabling intricate forming and cutting tasks with minimal setup time.

For enhanced processing flexibility, the system integrates linear motor-driven punching units designed for rapid left-right movements. These units operate in tandem with other modules, optimizing workflow continuity and ensuring consistent output quality. The line’s intelligent control architecture allows real-time synchronization of all components, minimizing mechanical downtime and maximizing operational efficiency.

Material handling is streamlined via a gantry-style servo belt mechanism, featuring adaptive height adjustment to accommodate varying lamination thicknesses. This self-regulating system ensures uniform pressure distribution and precise alignment throughout the production cycle, even when processing materials with inconsistent profiles.

The CAH(223) - 400CK’s dual-platform discharge unit sets a new standard for continuous production. Its upward/downward lifting design incorporates an active-active operational mode, where one platform actively unloads finished materials while the other prepares for the next cycle. This innovative alternation eliminates bottlenecks, ensuring uninterrupted output and maximizing operational uptime.