CANWIN Group offers transformers for different applications:

• Power distribution general-purpose transformers

• Service transformers for electric power stations and other objects

• Converter transformers for direct-current drive in metallurgical, drill, gas-and-oil producing and other branches of industry

• Тransformers for converter installations of the urban transport (subway, tramway, trolleybus)

• Тransformers for converters of the excitation system of turbo and hydro-generators

Depending on the customer requirements, transformers can be of the following design versions:

Left

• HV winding inputs are on the left regarding the front (side of the rating plate)

Right

• HV winding inputs are on the right regarding the front (side of the rating plate)

• Up: inputs of the LV and HV windings are on the transformer upper cover

• Other design versions are up to the customer request

Product introduction

Epoxy resin casting dry-type power

Transformer is low-noise, low-loss type dry-type transformer.

Especially suitable for urban power grid, high-rise buildings, business centers, theaters, hospitals, hotels, tunnels, subways, underground power stations, laboratories, stations, docks, airports, integrated substations and other important places.

The magnetic core

Is made of cold-rolled electro-technical sheet steel with a heat-proof coating. Stacking technology

and “step-lap” cutting provide low level of no-load losses. Cutting of electro-technical steel is carried out on the automatic cutting line with the high cut accuracy.

High voltage windings

Are made in section-layer form with the series connection of sections. HV winding is made of insulated wire or foil on high accuracy coil-processing machines. Vacuum resin filling of windings is carried out during a completely automated process. Epoxy compound includes a number of components providing a good heat emission, and also a high thermos-stability.

Low voltage windings

Are made of foil on automatic winding machine with simultaneous winding of inter-laminar and frontal insulation. Number of cooling ducts in the winding depends on the transformer power. Ducts are provided with fiber glass profiles of a high heat resistance class. Windings are covered with insulating enamels and heat treated.

Transformer housing

Provides necessary protection degree of the active part. It is made of steel construction with walls, a bottom and a roof. The walls and the bottom have vent holes, providing a normalized cooling level of the transformer. Wide walls have access panels for access to adjusting taps. All walls are detachable, that assures visual inspection and maintenance service on a schedule date.

Transformers can be manufactured of the following design versions:

• Lеft: HV winding inputs are on the left regarding the front;

• Right: HV winding inputs are on the right regarding the front;

• Up: inputs of the LV and HV windings are on the transformer upper cover.

• Other design versions are up to the customer re- quest.

• Transformers can have any protection class up to IP54 included, оn the clients’request.

Transformer is low-noise, low-loss type dry-type transformer.

Especially suitable for urban power grid, high-rise buildings, business centers, theaters, hospitals, hotels, tunnels, subways, underground power stations, laboratories, stations, docks, airports, integrated substations and other important places.

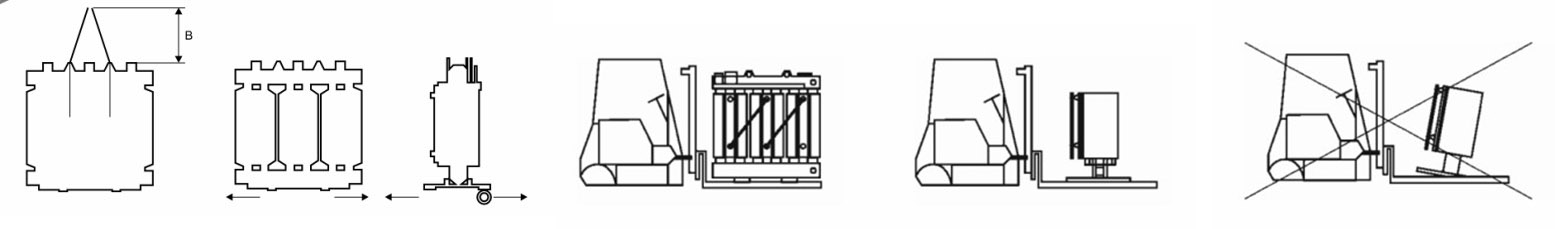

Transformers are equipped with ground wheels pivotal in two directions. For dragging, you can use the special lifting lugs which are near the wheels. If the transformer is not equipped with a pallet, lifting to the electric car can be carried out only in the longitudinal direction.

FAQ

1.What can we do for you ?

We can provide you with power transformer manufacturing equipment and technical services for you to create a strong competitive transformer factory. We can provide you with special transformer OEM/ODM services. Even if you do not have the ability to produce, you can also go to pick up your order. We can provide you with all the high quality raw materials you need for your transformer plant production. Of course, the price must be very attractive!

2.How many years have your company made this kind of equipment?

We have 20 years of marketing experience and a 200,000 square foot modern manufacturing center.

3.Which certificate do you have for your equipment?

We have owned 56 patents in fields of the international invention. ISO9001 / SO14001/ STL / ASTA / KEMA

4.Can you send your staff to install the equipment for us?

After - sales free to provide engineers on-site installation and debugging and professional technical training.Answer your technical or technical questions by phone or in writing.

5.Do you have any agent in our country?

CANWIN transform and upgrade traditional industries as an opportunity to deepen the " one belt and one road" strategic layout, deepen cooperation with foreign markets. in the form of cooperation and mutual benefit, set up the transformer manufacturing center and core processing base in the Middle East, India. Dubai. Vietnam. Thailand. etc.In the future, CANWIN will move towards the direction of intelligent equipment leader, making China a global reputation!

CONTACT US

LEAVE A MESSAGE

Please fill out and submit the form below, we will contact you in 48 hours, thank you!

RECOMMENDED

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.