When the transformer oil level does not conform to the oil temperature, that is, does not conform to the temperature curve, it is judged that the oil level is abnormal. Abnormal oil level is mainly manifested as false oil level and low oil level.

(1) Failure of the oil level indicator: check and repair the oil level indicator.

(2) The respirator is blocked, so that air cannot enter when the oil level drops, and the oil level indication is too high: clear the respirator.

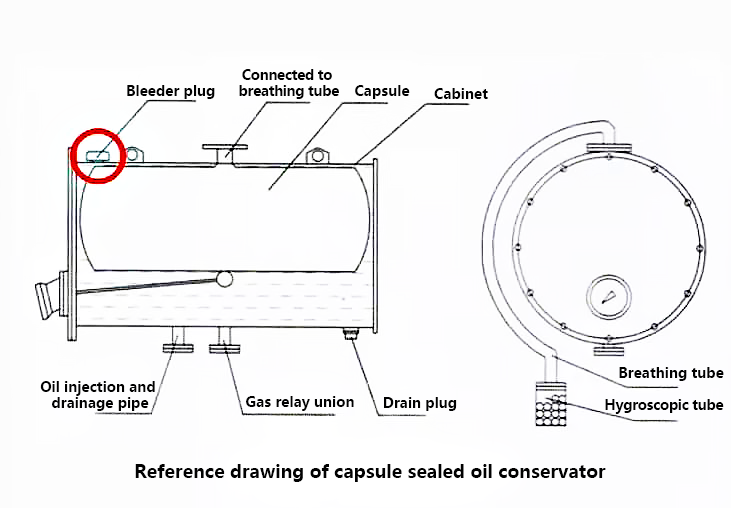

(3) Gas accumulates in the oil chamber of the oil conservator, making the oil level higher than the actual oil level: the oil conservator must be filled and exhausted.

(4) The oil chamber of the oil conservator is poorly sealed (the diaphragm or capsule is broken, the bellows is cracked, etc.), so that the oil level enters the diaphragm or capsule, and the oil level is low: overhaul the oil conservator.

(5) The transformer leaks seriously, causing the oil level to be low: deal with the leak point and refill the oil.

Transformer classification

Transformer is a kind of electrical equipment for energy exchange. According to different structures and cooling and insulating media, it can be divided into the following three categories: oil-immersed power transformers, gas-insulated power transformers, and dry-type power transformers.

Causes of Abnormal Oil Level in Transformer

When the transformer oil level does not conform to the oil temperature, that is, does not conform to the temperature curve, it is judged that the oil level is abnormal. Abnormal oil level is mainly manifested as false oil level and low oil level.

(1) Failure of the oil level indicator: check and repair the oil level indicator.

(2) The respirator is blocked, so that air cannot enter when the oil level drops, and the oil level indication is too high: clear the respirator.

(3) Gas accumulates in the oil chamber of the oil conservator, making the oil level higher than the actual oil level: the oil conservator must be filled and exhausted.

(4) The oil chamber of the oil conservator is poorly sealed (the diaphragm or capsule is broken, the bellows is cracked, etc.), so that the oil level enters the diaphragm or capsule, and the oil level is low: overhaul the oil conservator.

(5) The transformer leaks seriously, causing the oil level to be low: deal with the leak point and refill the oil.

Matters needing attention in transformer oil discharge

(1) Open the vent hole of the oil conservator or oil tank to break the vacuum environment.

(2) When the oil in the oil storage tank does not need to be discharged, the butterfly valve of the gas pipeline can be closed, and only the oil in the oil tank can be discharged. (When overhauling the part below the oil conservator, such as bushing replacement work)

(3) The amount of oil discharged should be calculated according to the scope of maintenance. (Replacement of bushing, pressure relief valve, vacuum butterfly valve, and overall transformer overhaul have different oil discharge volumes)

(4) Pay attention to the temperature and humidity when discharging oil, and the oil discharge should be carried out at a relative humidity of ≤75%.

Note: Be sure to open the vent plug before draining oil

Precautions for Oil Filling of Transformer

(1) The main body of the transformer should be vacuumed before large-scale oil filling, and a connecting pipe should be installed between the tap changer and the main body before vacuuming. (If the gas and oil conservator cannot be evacuated, the butterfly valve of the oil conservator should be closed)

(2) Vacuum, the vacuum value should reach 133pa, and keep it for a certain period of time (110 kV for 4 hours, 220 kV for 8 hours). Vacuuming is strictly prohibited in rainy and foggy weather such as humidity greater than 75%.

(3) After the vacuum degree is maintained for a certain period of time, start oil injection. Oil injection should be from the oil inlet valve at the bottom of the main transformer oil tank, and stop oil injection when the injection distance is 200mm-300mm from the top of the tank.

Precautions for Oil Supplementation of Transformer

(1) When the transformer is filled with oil after vacuum oil filling, it needs to be injected through the oil filling pipe of the oil conservator, and it is strictly forbidden to inject from the valve of the lower oil tank.

(2) For the vent holes such as the casing riser seat and the upper pipe of the radiator, the exhaust should be exhausted several times until exhausted.

(3) The gas inside the oil chamber of the oil conservator should be exhausted to prevent false oil level. For oil conservators with different structures, the exhaust methods are different, but in the end the core inspection principle: oil coming out of the exhaust hole means that the gas is discharged cleanly.

Safety Precautions

(1) Personnel working at heights must pass the physical examination and obtain a special operation certificate before they can engage in operations at heights.

(2) Personnel working at heights should use seat belts correctly, and seat belts are strictly prohibited from being hung low and high.

(3) Special personnel should be assigned to monitor the work at heights.

(4) Corresponding fire-fighting equipment should be equipped when oil operations are carried out on site.

CONTACT US

Take advantage of our unrivaled knowledge and experience, we offer you the best customization service.

LEAVE A MESSAGE

Please fill out and submit the form below, we will contact you in 48 hours, thank you!

RECOMMENDED

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.