Definition of electrical steel

Electrical steel, also known as silicon steel sheet, is an important soft magnetic alloy indispensable to power, electronics and military industry, as well as the largest output of metal functional materials, mainly used as the iron core of various motors, generators and transformers. Its production process is complex, manufacturing technology is strict, foreign production technology is protected in the form of patent, as the life of the enterprise. The manufacturing technology and product quality of electrical steel plate is one of the important signs to measure the development level of special steel production and science and technology in a country. At present, the quantity, quality and specification of cold rolled electrical steel in China cannot meet the needs of energy (power) industry development, and there is a big gap between China and Japan in terms of production technology, equipment, management and scientific research.

Introduction to Electrical steel

Electrical steel has a hundred years of history, including Si<0.5% electrical steel and Si content of 0.5~6.5% silicon steel, mainly used for all kinds of motor, transformer and ballast iron core, is an indispensable important soft magnetic alloy in power, electronics and military industry. Electrical steel has the largest amount of magnetic materials and is also an important metal functional material for energy saving. Electrical steel, especially oriented silicon steel manufacturing process and equipment complex, strict composition control, long manufacturing process, and affect the performance of the factors, so often the orientation silicon steel product quality as an important sign to measure the level of special steel manufacturing technology, and obtain the special steel in the "art product" reputation.

Electro-deposited copper foil

Product features

Copper foil has low surface oxygen characteristics and can be attached to a variety of different substrates, such as metal, insulation materials, etc., with a wide temperature range. Mainly used in electromagnetic shielding and antistatic, the conductive copper foil on the substrate surface, combined with the metal substrate, has excellent conductivity, and provides electromagnetic shielding effect. It can be divided into: self-adhesive copper foil, double guide copper foil, single guide copper foil, etc. Electronic grade copper foil (purity more than 99.7%, thickness of 5um-105um) is one of the basic materials of the electronic industry. With the rapid development of the electronic information industry, the use of electronic grade copper foil is increasing. The products are widely used in industrial calculators, communication equipment, QA equipment, lithium ion batteries. TV sets, VIDEO recorders, CD players, photocopiers, telephones, heating and cooling air conditioners, automotive electronic components, game machines, etc. The demand for electronic grade copper foil, especially for high performance electronic grade copper foil, is increasing day by day in domestic and foreign markets.

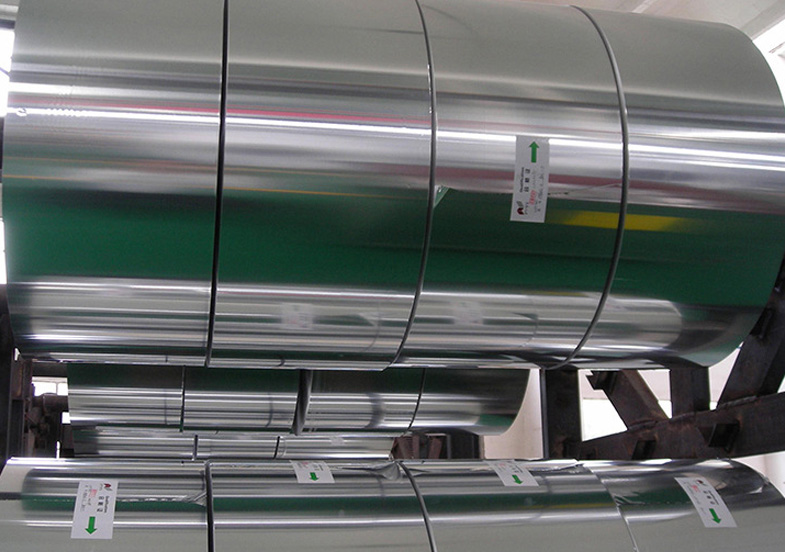

Electro-Aluminum Foil

Transformer aluminum foil: the strip is generally 1060 aluminum plate and belt. Its aluminum content reaches 99.6% or more, which is also known as pure aluminum plate. It belongs to a common series in the aluminum plate and belt family. The advantage of this series aluminum plate: the most commonly used series, the production process is relatively single, the technology is relatively mature, the price relative to other high-grade alloy aluminum plate has a huge advantage. With good elongation and tensile strength, it can fully meet the requirements of conventional processing (stamping, stretching) with high formability. Industrial pure aluminum, with high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but low strength, heat treatment can not strengthen the machinability is not good. Gas welding, hydrogen welding and contact welding, not easy to braze; Easy to withstand all kinds of pressure processing and extension, bending.

2. Chemical composition of aluminum foil 1060

Aluminum Al: 99.60, Silicon Si: 0.25, Copper Cu: 0.05, Magnesium Mg :0.03, Zinc Zn: 0.05, Manganese Mn :0.03, Titanium Ti :0.03, vanadium V: 0.05, Fe: 0.350, note: Single :0.03.

3. Material Editing

Material: 1060-o, 1050,1050 A, 1070,1070A, 1350

Purpose: aluminum foil and transformer strip for dry type transformer

Thickness: 0.2mm--3.0mm, width: 20mm-1650mm.

Description: Smooth surface, no scratches. The edge can be chamfered (rounded corner, rounded edge), no burr, resistivity less than or equal to 0.028.

Packing: wooden pallet, inner diameter 300mm or 500mm. Moisture-proof paper packaging, intermediate paper sleeve.

4. Application Editing

Transformer application of aluminum foil to make dry type transformer has small volume, light weight, good insulation performance, flame retardant, no pollution, little partial discharge, moisture proof, stable and reliable operation, low noise, low maintenance cost advantages, in the high-rise building, underground facilities, business center, residential, hotels and humid coastal areas and other applications.

FAQ

1.What can we do for you ?

We can provide you with power transformer manufacturing equipment and technical services for you to create a strong competitive transformer factory. We can provide you with special transformer OEM/ODM services. Even if you do not have the ability to produce, you can also go to pick up your order. We can provide you with all the high quality raw materials you need for your transformer plant production. Of course, the price must be very attractive!

2.How many years have your company made this kind of equipment?

We have 20 years of marketing experience and a 200,000 square foot modern manufacturing center.

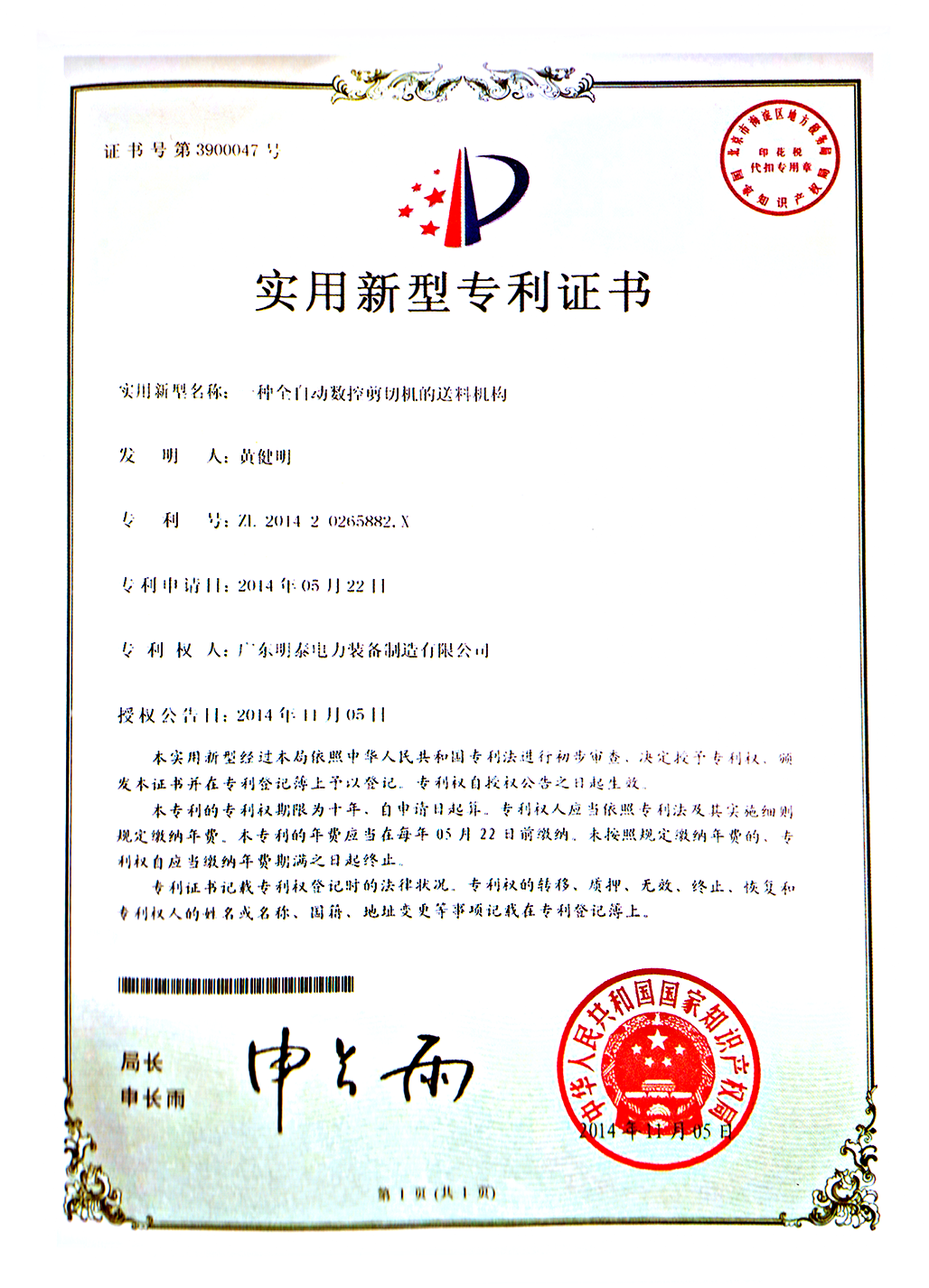

3.Which certificate do you have for your equipment?

We have owned 56 patents in fields of the international invention. ISO9001 / SO14001/ STL / ASTA / KEMA

4.Can you send your staff to install the equipment for us?

After - sales free to provide engineers on-site installation and debugging and professional technical training.Answer your technical or technical questions by phone or in writing.

5.Do you have any agent in our country?

CANWIN transform and upgrade traditional industries as an opportunity to deepen the " one belt and one road" strategic layout, deepen cooperation with foreign markets. in the form of cooperation and mutual benefit, set up the transformer manufacturing center and core processing base in the Middle East, India. Dubai. Vietnam. Thailand. etc.In the future, CANWIN will move towards the direction of intelligent equipment leader, making China a global reputation!

CONTACT US

LEAVE A MESSAGE

Please fill out and submit the form below, we will contact you in 48 hours, thank you!

RECOMMENDED

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.