Transformer is an important primary equipment in the power system, and its operational reliability has a great relationship with the safe and reliable operation of the power system. According to relevant statistics, the average accident rate of transformers of 110kV and above is about 0.69%, among which, due to the over-temperature operation of the winding, the insulation is aged, the winding is broken down, and the transformer burnout accident accounts for a considerable proportion. The heavy gas protection in the non-electrical protection of the transformer actually indirectly reflects the abnormal temperature of the transformer.

It can be seen that the measurement of transformer temperature is of great significance for the early warning and timely action of transformer accidents.

The service life of a transformer depends on its winding temperature, which plays a decisive role in the insulating material. When the insulation temperature of the transformer winding is in the transformer oil temperature range of 80 to 130 °C, the insulation aging rate will double for every 6 °C increase in temperature, that is, the insulation life will be reduced by 1/2, which is the "six degrees rule" of insulation aging.

During the operation of the transformer, it is generally stipulated that 85°C is the limit of the upper oil temperature. In Dongying area, when the upper oil temperature reaches above 80°C, the alarm signal "XX main transformer body oil temperature high alarm" and "XX main transformer body oil temperature" will be issued. high warning".

The temperature of oil-immersed transformers, both the transformer oil and winding, can be measured using a temperature gauge inserted into the transformer oil at the top of the casing. This allows for monitoring of the transformer's overall temperature. As the transformer windings can generate excess heat during operation, they typically have a higher temperature than the oil. The hottest spot inside the transformer, known as the hot spot temperature, is a key factor in predicting insulation aging. This hot spot is usually located near the ends of the windings but is difficult to accurately measure. To monitor this internal temperature, a transformer winding temperature indicator is often used instead. Therefore, most oil-immersed transformers are equipped with both a top oil and winding temperature gauge.

The black pointer on the thermometer indicates the actual operating temperature, and the red pointer indicates the set upper limit alarm temperature. When the oil temperature of the upper layer of the transformer exceeds this value, it will alarm, the two pointers collide to make the electrical contact conduct, and an alarm signal will be issued, and there is a protrusion on the red needle. When the oil temperature exceeds the maximum temperature during operation, the black pointer will drive the red needle. The pointer rotates, at this time the red needle indicates the highest temperature reached during operation

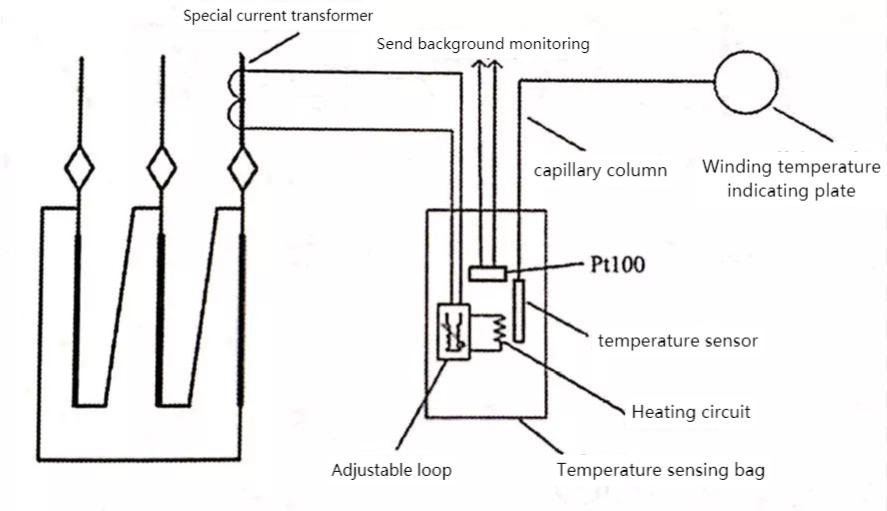

The winding temperature in transformer can be considered as the superposition of the oil temperature of the top layer of the transformer and the temperature rise of the winding to the oil. Generally, the load current of the transformer is added on the basis of the transformer oil temperature measurement system, and the temperature rise of the winding to the oil is simulated by the thermal simulation method, so as to finally obtain the transformer winding temperature indicator. The schematic diagram of the specific implementation method is shown in the following figure.

Oil-immersed transformer winding temperature Tw can be equivalent to:

Tw=T0+k*△Two

In the formula, T0 is the oil temperature of the top layer of the transformer, △Two is the copper oil temperature difference, obtained by thermal simulation, k is the thermal coefficient, which is related to the transformer capacity, winding structure, etc. The temperature rise of the winding to the oil △Two depends on the winding flow. passing current.

The measurement system is mainly composed of a temperature sensing package, a transformer winding temperature measurement compensation circuit, and a sensor. Among them, the temperature measurement compensation circuit and the transformer winding temperature sensor are all in the temperature sensing package, and the temperature sensing package is immersed in the top oil of the transformer to sense the top oil temperature. The sensor consists of two parts: the temperature sensor connected to the on-site winding temperature in transformer mechanical meter, the collected temperature value is reflected in the temperature indicator plate reading; the Pt100 thermal resistance, whose resistance value changes with the temperature change, the collected temperature value is used to send the computer Background monitoring system.

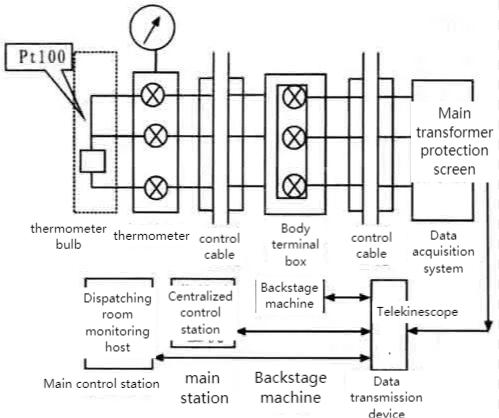

The oil temperature information is transmitted to the dispatch center through the connection method shown in the figure below to realize real-time monitoring of the upper oil temperature and winding temperature.

1. How to judge whether the temperature change of the transformer is normal or abnormal?

While the transformer is in operation, energy losses in both the iron core and windings are converted into heat. This results in a rise in temperature throughout various parts of the transformer, which then dissipates through radiation and conduction. Once a balance is reached between heat generation and dissipation, the temperature stabilizes for each component. The amount of iron loss remains consistent while the copper loss varies depending on the load. To assess the transformer's performance, take note of external temperature, top oil temperature, load, and oil level height during inspection. These values can be compared to previous readings to determine if the transformer is functioning properly.

If the oil temperature is above 10°C compared to normal in the same circumstances, or if the temperature continues to climb without a change in load and the cooling device is functioning correctly, this indicates an internal issue with the transformer. It is important to check for any errors or failures in the thermometer. The main insulation of most transformers (known as Class A insulation) is made of paper and can withstand temperatures up to 105°C. Typically, the winding temperature will be 10-15°C higher than the surface temperature of the oil. For instance, if the oil surface measures 85°C, then expect a winding temperature between 95-100°C.

2. Reasons for abnormal temperature of transformer

① Abnormal temperature caused by internal fault

If a transformer experiences internal faults, such as inter-turn or inter-layer short circuits, several issues may occur. The coil will discharge to the enclosure, causing heating in the internal lead joints. Additionally, the iron core's multi-point grounding can increase eddy currents and result in overheating. In some cases, leakage flux may form a loop with the iron oil tank and cause heat buildup. If any other factors cause abnormal temperatures in the transformer, gas or differential protection may activate. In severe cases, oil may need to be injected into the explosion-proof pipe or pressure relief valve. In this situation, it is advisable to stop and inspect the transformer.

②The abnormal temperature caused by the abnormal operation of the cooler

Abnormal temperature caused by abnormal operation or failure of the cooler, such as outage of submersible pump, damaged fan, fouling of cooling pipes, poor cooling efficiency, and failure of radiator valve to open. The cooling system should be maintained and flushed in time or a backup cooler should be put in, otherwise the load of the transformer should be adjusted.

③ If the temperature indicator has errors or the indication fails, the thermometer should be replaced.