Xa undoqo we-transformer upakishwe, zeziphi iindlela zokuthunga? Ziziphi iimpawu zomntu ngamnye? Eli nqaku liqala kwisayensi edumileyo yeentsimbi zentsimbi, kwaye andisa kwaye andisa ukujonga indlela yomthungo wamaphepha ensimbi ye-silicon xa iintsimbi ze-iron zipakishwe. (Ukuba kukho naziphi na iimpazamo okanye izongezo, nceda ushiye umyalezo ekupheleni kwenqaku)

■ Imiba enxulumene nombindi wentsimbi

(1) Ummandla we-geometric cross-sectional area: ubhekiselele kwindawo enqamlezileyo yendawo ethathwe ngumbindi wentsimbi.

(2) Ummandla osebenzayo onqamlezileyo: ubhekisa kwindawo enqamlezileyo ye-silicon yentsimbi efunyenwe ngokususa umsantsa phakathi kwamaphepha ensimbi ye-silicon kunye nommandla othathwe bubunzima befilimu yepeyinti ekhuselayo ukusuka kwi-geometric cross-sectional. indawo.

(3) I-Lamination coefficient: ibhekisela kumlinganiselo wendawo esebenzayo ye-cross-sectional ye-core ukuya kwindawo yejometri ye-cross-sectional. I-lamination factor inxulumene nobukhulu kunye nokuthe tyaba kweshiti lensimbi ye-silicon kunye nobukhulu bomaleko wokugquma phakathi kwamaphepha. Umzekelo, xa kusetyenziswa i-0.35mm engqingqwa ye-silicon sheet yensimbi, i-lamination factor iphakathi kwe-0.91-0.96.

(4) Ukuzalisa i-coefficient: ekwabizwa ngokuba yi-coefficient yokusetyenziswa, ibhekisela kumlinganiselo wendawo enqamlezileyo yekholomu yentsimbi ehlanganiswe kwimilo yeleli ukuya kwindawo yesangqa sekholamu engundoqo. Ngaphantsi kobubanzi obuthile, inkulu indawo ye-cross-sectional yekholomu engundoqo, oko kukuthi, inani lamanyathelo, inkulu into yokuzalisa. Nangona kunjalo, amanyathelo amaninzi akhona, ngakumbi ukucaciswa kwe-laminations, enzima inkqubo yokuvelisa engundoqo.

■ Indlela ye-silicon ye-steel seam seam

Xa undoqo we-transformer upakishwe, kukho ezi ndlela zintathu zilandelayo zokuthunga zamaphepha ensimbi ye-silicon.

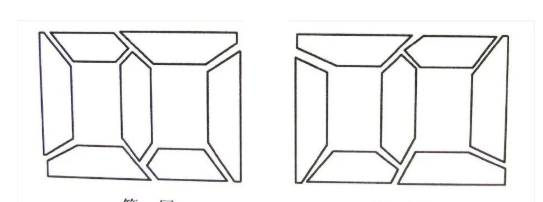

Umthungo othe ngqo - kuphela kwi-silicone sheet sheet eshushu esongiweyo

Njengoko kubonisiwe kwi-Figure 1. Iimpawu zayo kukuba ukucutshungulwa kunye ne-lamination zilula, kwaye indawo edibeneyo inkulu, ngoko i-core yentsimbi edibeneyo inamandla okwakhiwa kakuhle, ingqibelelo eyomeleleyo, kwaye akukho lula ukukhubaza, kodwa kunokubakho kuphela. isetyenziselwa ukwenza i-silicone sheets yentsimbi eshushu. Ukuba isetyenziselwa amacwecwe ensimbi ye-silicon aqengqeleke ngokubanda aneempawu ezintle zemagneti ecaleni kwendlela yokuqengqeleka, kuba i-magnetic flux kumthungo ayidluli kwicala lokuqengqeleka, iipropathi zemagneti ziya kuwohloka, okukhokelela ekonyukeni kokungabikho komthwalo. ilahleko.

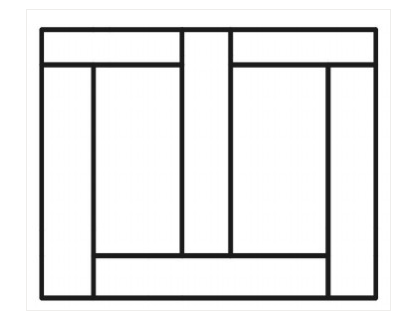

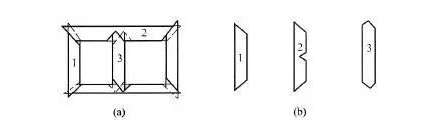

I-semi-straight kunye ne-semi-miter joints-yamaphepha entsimbi ye-silicon aqengqeleke ngokubanda.

njengoko kubonisiwe kumfanekiso wesi-2. Isetyenziselwa i-silicone yentsimbi eqengqelekayo egotyiweyo. Uphawu lolu hlobo lomthungo kukuba umthungo othe ngqo kunye ne-miter seam zivela ngokutshintshanayo kwi-core lamination. Xa ububanzi bephepha lekholamu engundoqo kunye nephepha ledyokhwe yentsimbi zifana, i-miter seam yi-45 °. I-50% yeekona, iipropathi zamagnetic ziphuculwe kakhulu xa kuthelekiswa ne-seams ngokuthe ngqo, isakhiwo sinokwethenjelwa, ukucheba kunye nokupakisha kwakhona kukulungele, kwaye izinga lokusetyenziswa kwamaphepha ensimbi ye-silicon liphezulu. Nangona kunjalo, ngenxa yokuba kusekho inxenye yomthungo othe ngqo, umkhombandlela we-silicone yentsimbi eqengqelekisiweyo egobileyo ayisetyenziswanga ngokupheleleyo, ngoko ke ilahleko engenamthwalo yombindi wentsimbi ayinakuncitshiswa.

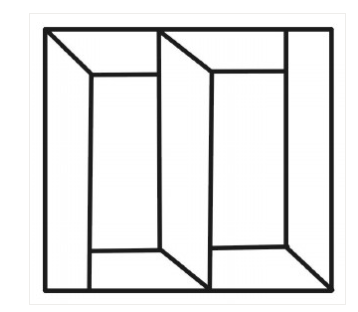

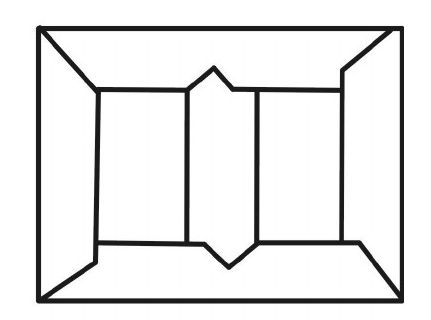

Umthungo ogcweleyo wemiter - yentsimbi epholileyo eqengqelekayo ye-silicone sheet

Njengoko kubonisiwe kwi-Figure 3. Ukuze kuncitshiswe ngakumbi ilahleko yokungabikho komthwalo wentsimbi engundoqo kwaye usebenzise ngokupheleleyo iimpawu zeshiti lensimbi ye-silicon epholileyo ejikelezayo, kufuneka kusetyenziswe i-oblique joints, ukwenzela ukuba isalathiso se-oblique sisetyenziswe. i-magnetic flux iyahambelana nesalathiso sokuqengqeleka kwiphepha lensimbi ye-silicon, kwaye ilahleko engundoqo iyancitshiswa. Nangona kunjalo, olu hlobo lwenkqubo yomthungo luyinkimbinkimbi, kwaye ingqibelelo yentsimbi egciniweyo imbi.

QHAGAMSHELANA US

Thatha ithuba lolwazi lwethu kunye namava angenakuthelekiswa nanto, sikunika eyona nkonzo ilungileyo yokwenza ngokwezifiso.

i

i

SHIYA UMYALEZO

Nceda ugcwalise kwaye uthumele ifom engezantsi, siya kuqhagamshelana nawe kwiiyure ze-48, enkosi!

REIYAQHUBEKA

Zonke zenziwe ngokweyona migangatho ingqongqo yamazwe ngamazwe. Iimveliso zethu zifumene ubabalo kwiimarike zasekhaya nezangaphandle.