When the transformer core is stacked, what are the seam methods? What are the characteristics of each? This article starts from the popular science of iron cores, and expands and expands to check the seam method of silicon steel sheets when the transformer iron cores are stacked. (If there are any mistakes or additions, please leave a message at the end of the article)

■ Related concepts of iron core

(1) Geometric cross-sectional area: refers to the cross-sectional area of the space occupied by the iron core.

(2) Effective cross-sectional area: refers to the actual cross-sectional area of the silicon steel sheet obtained by subtracting the gap between the silicon steel sheets and the area occupied by the thickness of the insulating paint film from the geometric cross-sectional area.

(3) Lamination coefficient: refers to the ratio of the effective cross-sectional area of the core to the geometric cross-sectional area. The lamination factor is related to the thickness and flatness of the silicon steel sheet and the thickness of the insulating layer between the sheets. For example, when a 0.35mm thick silicon steel sheet is used, the lamination factor is generally between 0.91-0.96.

(4) Filling coefficient: also known as the utilization coefficient, it refers to the ratio of the cross-sectional area of the iron core column composed of the ladder shape to the area of the circumcircle of the core column. Under a certain diameter, the larger the cross-sectional area of the core column, that is, the more the number of steps, the larger the filling factor. However, the more steps there are, the more specifications of the laminations, which complicates the core manufacturing process.

■ Silicon steel sheet seam method

When the transformer core is stacked, there are the following three seaming methods for silicon steel sheets.

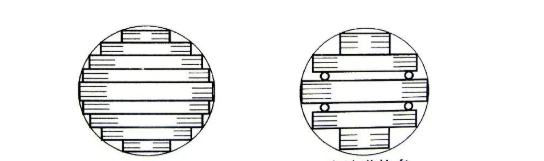

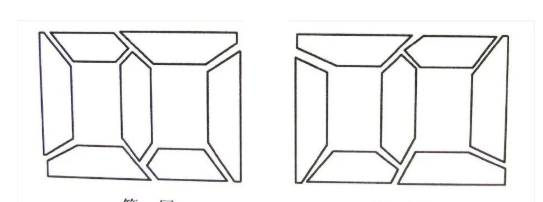

Direct seam - only for hot rolled silicon steel sheet

As shown in Figure 1. Its characteristics are that the processing and lamination are relatively convenient, and the overlapping area is large, so the laminated iron core has good structural strength, strong integrity, and is not easy to deform, but it can only be used for hot-rolled silicon steel sheets. If it is used for cold-rolled oriented silicon steel sheets with good magnetic properties along the rolling direction, since the magnetic flux at the seam does not pass along the rolling direction, the magnetic properties will deteriorate, resulting in an increase in no-load loss.

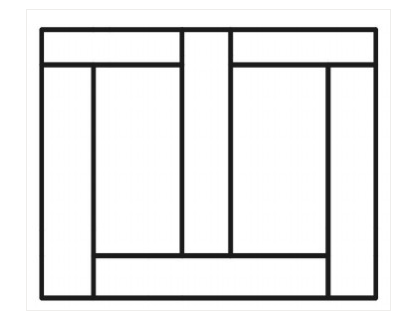

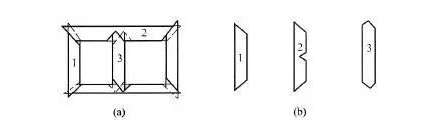

Semi-straight and semi-miter joints - for cold-rolled grain-oriented silicon steel sheets

as shown in picture 2. It is used for cold-rolled grain-oriented silicon steel sheet. The characteristic of this kind of seam is that the direct seam and the miter seam appear alternately in the core lamination. When the width of the core column sheet and the iron yoke sheet are the same, the miter seam is 45°. 50% of the corners, the magnetic properties are significantly improved compared to direct seams, the structure is reliable, the shearing and stacking are also convenient, and the utilization rate of silicon steel sheets is high. However, because there is still a part of the direct seam, the directionality of the cold-rolled grain-oriented silicon steel sheet is not fully utilized, so the no-load loss of the iron core cannot be minimized.

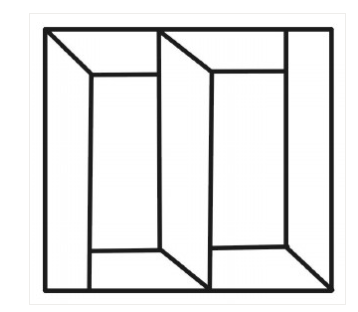

Full miter seam - for cold rolled grain oriented silicon steel sheet

As shown in Figure 3. In order to further reduce the no-load loss of the iron core and make full use of the characteristics of the cold-rolled oriented silicon steel sheet, full oblique joints should be used, so that the direction of the magnetic flux is consistent with the rolling direction of the silicon steel sheet, and the core loss is minimized. However, this kind of seam process is complicated, and the integrity of the stacked iron core is poor.

CONTACT US

Take advantage of our unrivaled knowledge and experience, we offer you the best customization service.

LEAVE A MESSAGE

Please fill out and submit the form below, we will contact you in 48 hours, thank you!

RECOMMENDED

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.