Lapho umgogodla we-transformer umboziwe, yiziphi izindlela zokuthunga? Yiziphi izici zento ngayinye? Lesi sihloko siqala kwisayensi edumile yama-iron cores, futhi inweba futhi inwebe ukuze kuhlolwe indlela yomthungo yamashidi ensimbi ye-silicon lapho ama-iron cores e-transformer estakiwe. (Uma kukhona amaphutha noma izengezo, sicela ushiye umlayezo ekugcineni kwesihloko)

■ Imicondvo lehlobene yensimbi

(1) Indawo ephambanayo yeJiyomethri: ibhekisela endaweni ephambanayo yesikhala esithathwe ingqikithi yensimbi.

(2) Indawo esebenza ngempumelelo ephambanayo: ibhekisa endaweni ephambanayo yangempela yeshidi lensimbi ye-silicon etholwe ngokukhipha igebe phakathi kwamashidi ensimbi ye-silicon kanye nendawo esetshenziswa ukushuba kwefilimu kapende evikelayo ukusuka ku-geometric cross-sectional. indawo.

(3) I-Lamination coefficient: ibhekisela esilinganisweni sendawo esebenza ngempumelelo ye-cross-sectional of the core endaweni ye-geometric cross-sectional. Isici se-lamination sihlobene nogqinsi kanye nokucaba kweshidi lensimbi ye-silicon kanye nogqinsi longqimba oluvikelayo phakathi kwamashidi. Isibonelo, lapho kusetshenziswa ishidi le-silicone eliwugqinsi elingu-0.35mm, isici se-lamination ngokuvamile siphakathi kuka-0.91-0.96.

(4) I-coefficient yokugcwalisa: eyaziwa nangokuthi i-coefficient yokusetshenziswa, ibhekisela esilinganisweni sendawo ephambanayo yekholomu ewumgogodla wensimbi eyakhiwe ukuma kwesitebhisi endaweni yesiyingi sekholomu ewumgogodla. Ngaphansi kobubanzi obuthile, indawo enkulu ye-cross-sectional yekholomu eyinhloko, okungukuthi, inani lezinyathelo eziningi, likhulu isici sokugcwalisa. Kodwa-ke, uma kunezinyathelo ezengeziwe, ukucaciswa okwengeziwe kwama-laminations, okwenza kube nzima inqubo yokukhiqiza engumongo.

■ Indlela ye-seam ye-silicone yensimbi

Lapho umgogodla we-transformer umboziwe, kunezindlela ezintathu ezilandelayo zokuthunga zamashidi ensimbi ye-silicon.

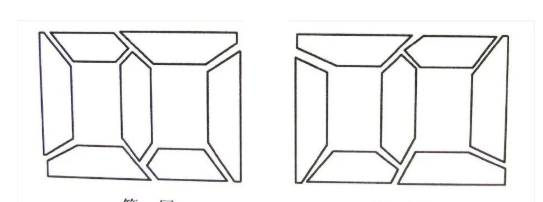

Umthungo oqondile - kuphela weshidi lensimbi ye-silicon egoqwe eshisayo

Njengoba kuboniswe kuMfanekiso 1. Izici zayo ukuthi ukucutshungulwa kanye ne-lamination kulula kakhulu, futhi indawo egqagqene inkulu, ngakho-ke insimbi yensimbi ene-laminated inamandla amahle esakhiwo, ubuqotho obuqinile, futhi akulula ukuguqula, kodwa ingaba kuphela. esetshenziselwa amashidi ensimbi ye-silicon egoqwe ashisayo. Uma isetshenziselwa amashidi ensimbi ye-silicon egoqelwe ngokubanda anezici ezinhle kazibuthe eduze nendawo eginqikayo, njengoba i-flux kazibuthe emthungoni ayidluli lapho iginqika khona, izakhiwo kazibuthe zizowohloka, okuholela ekwandeni kokungalayishi. ukulahlekelwa.

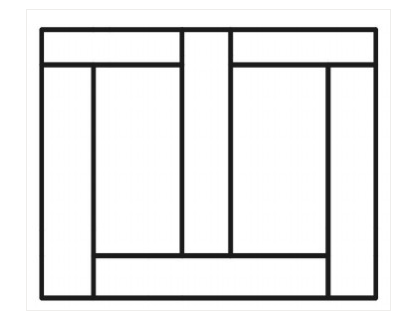

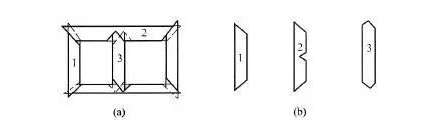

Amajoyinti aqondile kanye ne-semi-miter - amashidi ensimbi ye-silicon egoqwe okusanhlamvu

njengoba kukhonjisiwe esithombeni sesi-2. Isetshenziselwa ishidi lensimbi ye-silicone egoqwe okusanhlamvu. Isici salolu hlobo lomthungo ukuthi i-seam eqondile kanye ne-miter seam ibonakala ngokushintshana ku-core lamination. Uma ububanzi beshidi lekholomu eyinhloko kanye neshidi lejoka lensimbi kufana, umthungo we-miter ungu-45 °. I-50% yamakhona, izakhiwo kazibuthe zithuthukisiwe kakhulu uma kuqhathaniswa ne-seams eqondile, isakhiwo sinokwethenjelwa, ukugunda nokupakisha nakho kulula, futhi izinga lokusebenzisa amashidi ensimbi ye-silicon liphezulu. Kodwa-ke, ngenxa yokuthi kusekhona ingxenye yomthungo oqondile, isiqondiso seshidi lensimbi ye-silicon egoqelwe okusanhlamvu ayisetshenziswa ngokugcwele, ngakho-ke ukulahlekelwa okungalayishiwe kwensimbi akukwazi ukuncishiswa.

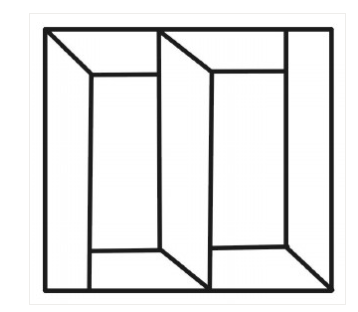

Umthungo ogcwele we-miter - weshidi lensimbi eligoqiwe eligoqiwe le-silicon

Njengoba kuboniswe kuMfanekiso 3. Ukuze kuqhutshekwe kuncishiswe ukulahlekelwa okungenamthwalo wensimbi futhi usebenzise ngokugcwele izici zeshidi lensimbi yensimbi egoqelwe ebandayo, kufanele kusetshenziswe amajoyinti agcwele ama-oblique, ukuze isiqondiso i-magnetic flux ihambisana nokugoqa kweshidi lensimbi ye-silicon, futhi ukulahlekelwa okuyinhloko kuyancipha. Kodwa-ke, lolu hlobo lwenqubo yomthungo luyinkimbinkimbi, futhi ubuqotho bomgogodla wensimbi oyisitaki abulungile.

CONTACT E-US

Thatha ithuba lolwazi lwethu nolwazi olungenakuqhathaniswa, sikunikeza isevisi engcono kakhulu yokwenza ngokwezifiso.

.

.

SHIYA UMLAYEZO

Sicela ugcwalise futhi uthumele ifomu elingezansi, sizokuthinta emahoreni angama-48, ngiyabonga!

REKUNCONYWA

Wonke akhiqizwa ngokuvumelana nezindinganiso zamazwe ngamazwe eziqinile. Imikhiqizo yethu ithole umusa kuzo zombili izimakethe zasekhaya nezangaphandle.