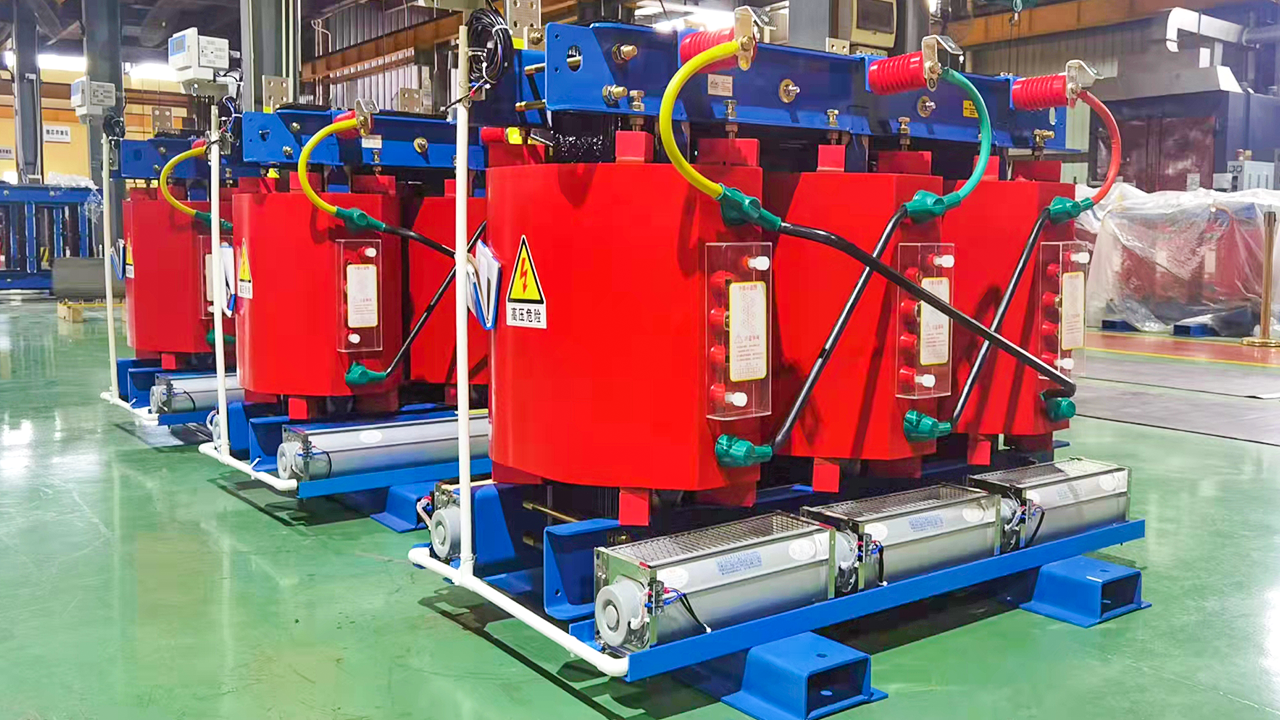

Dry-type transformers are widely used in local lighting, high-rise buildings, airports, dock CNC machinery and equipment, etc. Simply put, dry-type transformers refer to transformers whose iron cores and windings are not impregnated with insulating oil.

1. Technical parameters of dry-type transformer

Dry-type transformers are widely used in local lighting, high-rise buildings, airports, dock CNC machinery and equipment, etc. Simply put,

dry-type transformers refer to transformers whose iron cores and windings are not impregnated with insulating oil.

The relevant technical parameters of dry-type transformers include:

A. Rated capacity (kVA): The capacity that can be delivered during continuous operation at rated voltage and rated current.

B. Rated voltage (kV): The working voltage that a transformer can withstand during long-term operation.

To accommodate the needs of grid voltage changes, the high-voltage side of the transformer has taps,

which can be adjusted by adjusting the number of turns in the high-voltage winding to regulate the output voltage on the low-voltage side.

C. Rated current (A): The current allowed to pass through the transformer for a long time under rated capacity.

D. No-load loss (kW): The active power drawn when a rated voltage at rated frequency is applied to one winding terminal and

the remaining windings are open circuit.It is related to the performance and manufacturing process of the core silicon steel sheet,

as well as the applied voltage.

E. No-load current (%): When the transformer is under rated voltage and the secondary side is no-load, the current passing through

the primary winding is generally expressed as a percentage of the rated current.

F. Load loss (kW): Short-circuit the secondary winding of the transformer and apply a rated current to the primary winding at the

rated tap position. This is the power consumed by the transformer.

G. Impedance voltage (%): Short-circuit the secondary winding of the transformer and slowly increase the voltage on the primary winding.

When the short-circuit current of the secondary winding equals the rated value, the voltage applied on the primary side is the impedance

voltage. It is usually expressed as a percentage of the rated voltage.

H. Phase number and frequency: Three-phase is represented by S, and single-phase is represented by D. The frequency f of China's national

standard is 50Hz.There are countries abroad with 60Hz (such as the United States).I. Temperature rise and cooling: The difference between

the temperature of the transformer winding or upper oil layer and the temperature of the surrounding environment is called the temperature

rise of the winding or upper oil layer. The limit value of the temperature rise of the oil-immersed transformer winding is 65K, and the

temperature rise of the oil surface is 55K.There are also various cooling methods: oil-immersed self-cooling, forced air cooling, water cooling,

tube type, sheet type, etc.

J. Insulation level: There are standards for insulation levels. The insulation level of a transformer with a rated high voltage of 35 kV and a rated

low voltage of 10 kV is represented as LI200AC85/LI75AC35, where LI200 indicates that the transformer has a high-voltage lightning impulse

withstand voltage of 200 kV, a power frequency withstand voltage of 85 kV, and a low-voltage lightning impulse withstand voltage of 75 kV,

and a power frequency withstand voltage of 35 kV. The current insulation level of Aux High-Tech Co., Ltd.'s oil-immersed transformer products

is LI75AC35, indicating that the transformer has a high-voltage lightning impulse withstand voltage of 75 kV and a power frequency withstand

voltage of 35 kV. Because the low voltage is 400 V, it can be ignored.

K. Connection group label: According to the phase relationship between the primary and secondary windings of the transformer, the transformer

windings are connected into various combinations, which are called the connection group of the windings. In order to distinguish different connection

groups, the clock notation is often used, that is, the phasor of the line voltage on the high-voltage side is used as the long hand of the clock,

fixed at 12, and the phasor of the line voltage on the low-voltage side is used as the short hand of the clock. The number of the short hand indicates

the connection group label. For example, Dyn11 indicates that the primary winding is (triangle) connected, and the secondary winding is (star) connected

with a center point, and the group number is (11) points.

2. Technical requirements for dry-type transformers

(1) Dry-type transformer body:

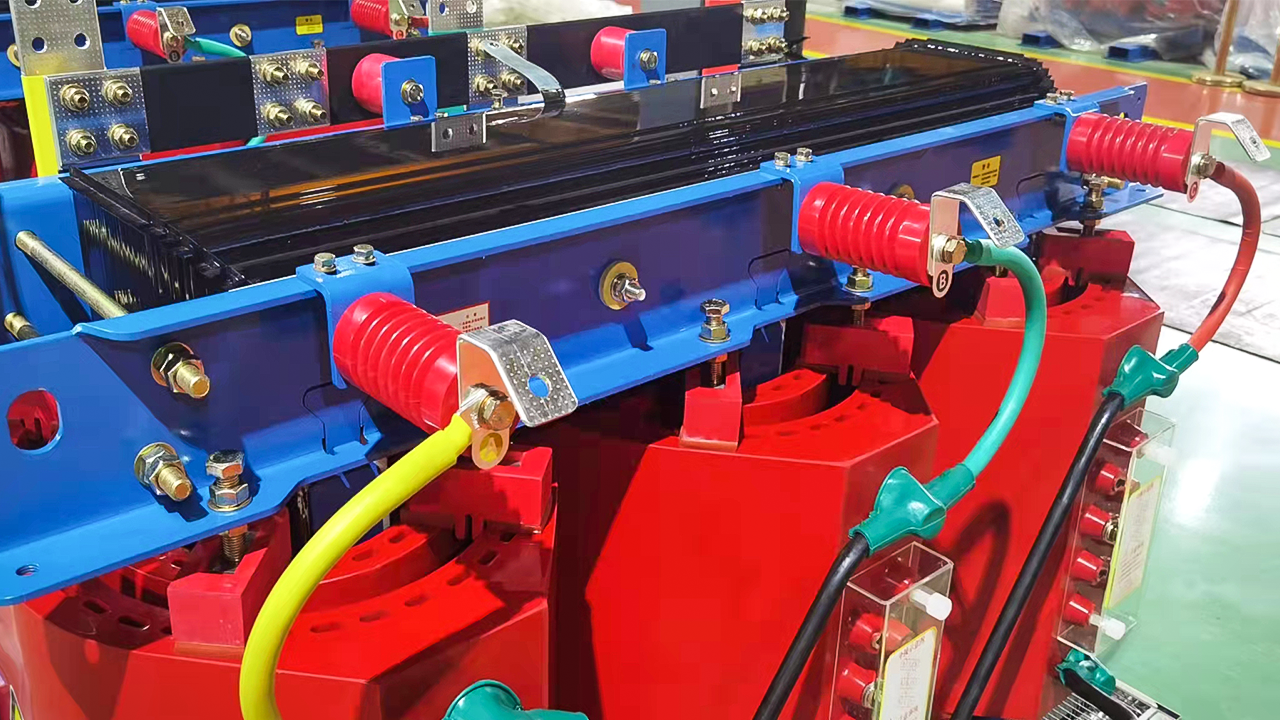

The high-voltage winding is made of copper wire and the low-voltage winding is made of copper foil.The coil is made of

imported epoxy resin glass fiber in full vacuum, with strong rigidity and mechanical strength, and good short-circuit resistance. The ampere-turns of

the high-voltage and low-voltage coils should be balanced.The epoxy resin glass fiber mixture has the same thermal expansion coefficient as copper conductors,

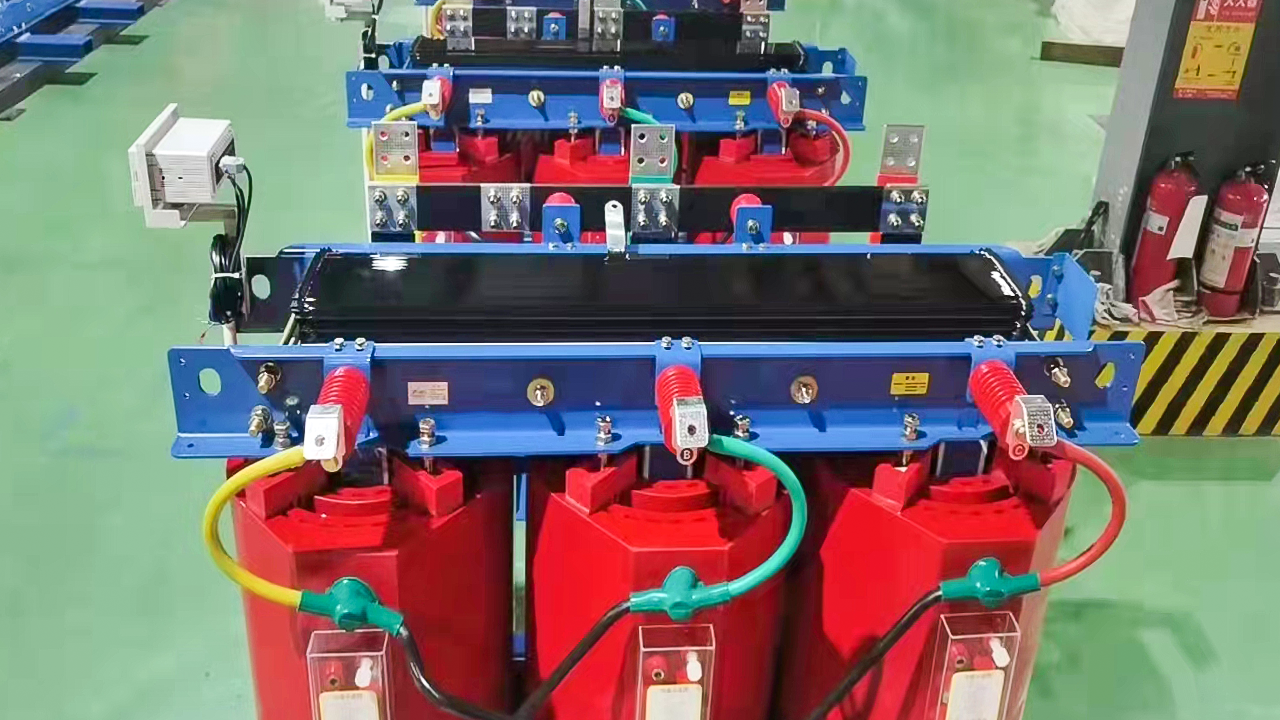

ensuring that the coil does not crack.It has strong heat dissipation performance.It is equipped with a temperature display control system that automatically

displays the temperature of the transformer's three-phase winding. When the temperature limit is reached, the thermostat can automatically send a signal

to control the fan start and stop, overtemperature alarm and action protection, and provide two passive contacts for automatically opening the substation

exhaust fan.

The iron core and all exposed metal parts should be subjected to rust prevention treatment.The nameplate is made of stainless steel, and the important data

related to the transformer are marked on the nameplate according to national standards.The assembled shell is assembled on site, and the shell material is

made of stainless steel plate.It has a communication 485 interface, which can relay the operating status of the transformer.

(2) The dry-type transformer can operate with 100% load under the condition that the fan is not running without overheating;it is allowed to operate with

50% overload under the condition that the fan is running normally, without overheating, alarming, or tripping.

(3) Dry-type transformer no-load loss:

The no-load loss is manufactured according to the national standard with negative error, not positive error, and must comply with the latest implementation

standards of Shandong Electric Power Company.

(4) Noise index:

The 2000KVA transformer is lower than 52ab when the normal operation fan is not running.

(5) Creepage distance:

Organic material not less than 20mmKV, porcelain not less than 18mm/KVo20, high-voltage side phase-to-ground and phase-to-phase net air safety

clearance (live parts) 2125mmo.

(6) The high-voltage incoming line is a cable, which meets the needs of upper or lower incoming lines;the low-voltage outgoing line is a bus duct, which

is an upper outgoing line.

(7) The cabinet should be equipped with access doors and inspection windows at the front and rear to facilitate inspection of the joints in various parts.

(8) Equipped with temperature measurement device and temperature control box;the micro switch in the control box adopts the manufacturer's accurate

24V power supply. All components should use the reinforced insulation type products certified by the "Two Departments".

(9) The terminal (10cm) of the hanging ground wire shall be left at a suitable position, and the rest shall be painted with corresponding phase color paint.

(10) Under normal working conditions and load conditions, the transformer has a service life of 230 years.

(11) Other contents not mentioned shall be implemented according to GB6450-86.

01

We can provide you with power transformer manufacturing equipment and technical services for you to create a strong competitive transformer factory

02

The company is a key enterprise in the field of electric power electrical equipment manufacturing in China, and a core professional equipment supplier of state grid, China southern power grid and many listed companies in the electric power industry.

03

The brand name of CANWIN has been registered in China, European Union, Africa, South America, United States, Russia, India, Southeast Asia and other 118 countries.

Q:

A:

Q:

A:

Q:

A:

Q:

A:

Q:

A:

CONTACT US

Take advantage of our unrivaled knowledge and experience, we offer you the best customization service.

LEAVE A MESSAGE

Please fill out and submit the form below, we will contact you in 48 hours, thank you!

RECOMMENDED

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.