Ama-transformer cores asetshenziswa kakhulu ngokuvamile enziwa ngamashidi ensimbi ye-silicon. I-Silicon steel iwuhlobo lwensimbi eyenziwe nge-silicon (i-silicon ibizwa nangokuthi i-silicon), kanti okuqukethwe kwayo kwe-silicon kungu-0.8 kuya ku-4.8%. Umnyombo wensimbi we-transformer wenziwe ngensimbi ye-silicon ngoba insimbi ye-silicon ngokwayo iyinto yamagnetic enokungena okuqinile kazibuthe.

Siyazi ukuthi i-transformer yangempela isebenza ngaso sonke isikhathi esimweni se-AC, futhi ukulahlekelwa kwamandla akukhona nje ukumelana nekhoyili, kodwa futhi kumgogodla wensimbi ngaphansi kwe-magnetization yamanje eshintshanayo. Ukulahlekelwa kwamandla kumongo wensimbi ngokuvamile kubizwa ngokuthi "ukulahlekelwa kwensimbi". Ukulahleka kwe-iron kubangelwa izizathu ezimbili, esinye "ukulahlekelwa yi-hysteresis" kanti esinye "ukulahlekelwa kwe-eddy yamanje".

Ukulahlekelwa kwe-hysteresis ukulahlekelwa kwensimbi okubangelwa i-hysteresis phenomenon phakathi nenqubo ye-magnetization ye-iron core. Ubukhulu balokhu kulahlekelwa bulingana nobukhulu bendawo evalwe yi-hysteresis loop yezinto. I-hysteresis loop yensimbi ye-silicon incane, futhi ukulahlekelwa kwe-hysteresis yensimbi ye-transformer kuncane, okunganciphisa kakhulu izinga lokukhiqiza ukushisa.

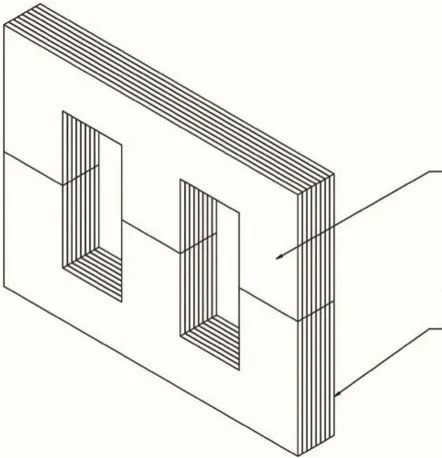

Njengoba insimbi ye-silicon inalezi zinzuzo ezingenhla, kungani ungasebenzisi lonke ucezu lwensimbi ye-silicon njengomgogodla wensimbi, kodwa futhi uyicubungule ibe ama-flakes? Lokhu kungenxa yokuthi i-chip core inganciphisa olunye uhlobo lokulahlekelwa kwensimbi - "ukulahlekelwa kwamanje kwe-eddy".

Lapho i-transformer isebenza, kuba khona amandla ashintshayo kukhoyili, futhi i-flux kazibuthe eyikhiqizayo iyashintshana. Lokhu kushintsha kwe-magnetic flux kubangela i-current in the iron core. I-current induced ekhiqizwa kumongo wensimbi izungeza endizeni iqonde ngqo lapho kugeleza khona kazibuthe, ngakho ibizwa ngokuthi i-eddy current.

Ukulahlekelwa kwamanje kwe-Eddy nakho kushisa umnyombo. Ukuze kuncishiswe ukulahlekelwa kwamanje kwe-eddy, i-iron core ye-transformer yenziwe ngamashidi ensimbi e-silicon ahlanganiswe komunye nomunye, ukuze i-eddy current idlule engxenyeni encane yesiphambano ku-loop encane futhi ende ukwandisa ukumelana. endleleni yamanje ye-eddy; ngesikhathi esifanayo, i-silicon ensimbi ye-silicon yenza i-Resistivity yezinto ezibonakalayo ikhule, ephinde isebenze ekunciphiseni ama-eddy currents.

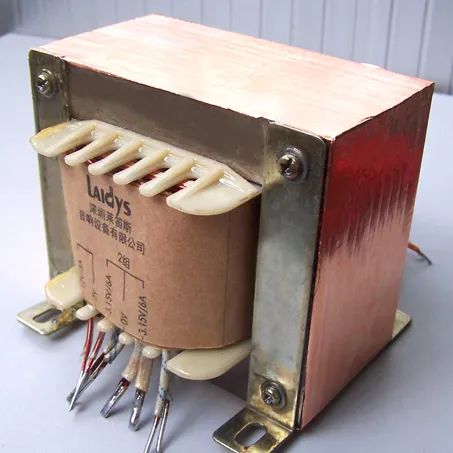

Ngomgogodla wensimbi we-transformer, kusetshenziswa ishidi lensimbi ye-silicon egoqwe ngokubanda enogqinsi oluyi-0.35mm. Ngokusho kobukhulu bensimbi edingekayo, inqunywa ibe yisiqephu eside, bese ihlanganiswa ibe yisimo "sosuku" noma umumo "womlomo". Uma sikhuluma ngokwethiyori, ukuze kwehliswe i-eddy current, ukuncipha kokuqina kweshidi lensimbi ye-silicon kanye nokuncipha kweshidi elihlukene, umphumela uba ngcono. Lokhu akugcini nje ukunciphisa ukulahleka kwamanje kwe-eddy kanye nokukhuphuka kwezinga lokushisa, kodwa futhi kusindisa izinto ezisetshenziselwa amashidi ensimbi ye-silicon.

Kodwa empeleni lapho wenza i-silicon steel sheet iron core. Akukona nje kuphela ezicini ezithandekayo ezibalwe ngenhla, ngoba ukukhiqizwa kwensimbi kuzokwandisa kakhulu amahora-amahora futhi kunciphise ukuphambana okuphumelelayo kwe-iron core. Ngakho-ke, lapho sisebenzisa amashidi ensimbi ye-silicon ukwenza ama-cores e-transformer, kufanele siqhubekele esimweni esithile, silinganise izinzuzo nezingozi, futhi sikhethe usayizi ongcono kakhulu.

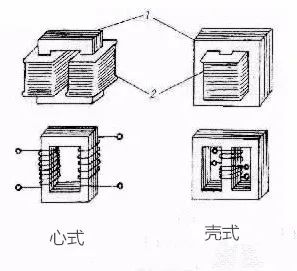

Ama-transformer enziwa ngokulandela isimiso sokungeniswa kwe-electromagnetic. Kunama-windings amabili, ukujika okuyinhloko, kanye nokujika kwesibili, inxeba emlenzeni ophakathi ovaliwe. Uma ukujikajika okuyinhloko kungamanga ku-voltage kagesi we-AC. Kukhona umsinga oshintshanayo eqenjini langempela le-Rao, futhi amandla kazibuthe ayasungulwa, futhi ukushintshashintsha okuyinhloko kazibuthe kukhiqizwa engxenyeni yensimbi ngaphansi kwesenzo samandla kazibuthe.

Ngokuqondene nokuthi kungani ingakhuliswa, futhi ikhishwe? Bese idinga ukuchazwa ngumthetho kaLenz. I-flux kazibuthe ekhiqizwa i-current induced ihlale ivimbela ukuguqulwa kwe-circular magnetic flux. Lapho i-flux yasekuqaleni kazibuthe ikhula, ukugeleza kazibuthe okukhiqizwe amandla kazibuthe kuphambene ne-flux yasekuqaleni kazibuthe, okungukuthi, eyesibili I-flux yamagnetic eyenziwe yi-winding iphambene ne-magnetic flux eyinhloko ekhiqizwa ukuzungeza okuyinhloko, ngakho-ke. i-voltage eshintshashintshayo enezinga eliphansi ivela endaweni ephendukayo yesibili. Ngakho-ke, i-iron core iyingxenye yesifunda kazibuthe ye-transformer.

I-Silicon steel sheet

Ishidi lensimbi ye-silicon elisetshenziswa ugesi livame ukubizwa ngokuthi i-silicon steel sheet noma ishidi le-silicon steel. Njengoba igama lisho, iyinsimbi kagesi ye-silicon enokuqukethwe kwe-silicon efinyelela ku-0.8% -4.8%, eyenziwe ngokugoqeka okushisayo nokubanda. Ngokuvamile, ubukhulu bungaphansi kwe-1mm, ngakho-ke kubizwa ngokuthi ipuleti elincane. Ngomqondo obanzi, i-silicon steel sheet ingeyesigaba samapuleti, futhi iyigatsha elizimele ngenxa yenhloso yalo ekhethekile. Ishidi le-silicone lensimbi elisetshenziswa ugesi linezakhiwo ezinhle kakhulu ze-electromagnetic futhi liyinto ebaluleke kakhulu futhi ebalulekile yamagnetic ezimbonini zamandla kagesi, ezokuxhumana kanye nezinsimbi.

(1) Ukuhlukaniswa kwamashidi ensimbi ye-silicon

A. Amashidi ensimbi ye-silicon angahlukaniswa abe yi-silicon ephansi kanye ne-silicon ephezulu ngokusho kokuqukethwe kwawo kwe-silicon. Amawafa e-silicon aphansi aqukethe i-silicon engaphansi kuka-2.8%, enamandla athile okusebenza, futhi asetshenziswa kakhulu ekwenzeni amamotho, aziwa kakhulu ngokuthi yi-motor silicon steel; Ukuze kwenziwe ama-cores e-transformer, aziwa kakhulu ngokuthi amashidi ensimbi ye-transformer silicon. Awukho umngcele oqinile phakathi kwalokhu okubili ekusetshenzisweni kwangempela, futhi ama-wafer ama-silicon aphezulu avame ukusetshenziselwa ukwenza amamotho amakhulu.

B. Ngokobuchwepheshe bokukhiqiza nokucubungula, ingahlukaniswa ngezinhlobo ezimbili: ukugoqa okushisayo nokugoqa okubandayo, futhi ukugoqa okubandayo kungahlukaniswa ngezinhlobo ezimbili: okungaqondile futhi okuqondile. Amashidi agoqwe abandayo anogqinsi olufanayo, ikhwalithi enhle yangaphezulu kanye nezakhiwo eziphakeme kazibuthe. Ngakho-ke, ngokuthuthukiswa kwemboni, amashidi ashisayo ajwayele ukushintshwa ngamashidi abandayo. "ukushintsha ukushisa kube amakhaza").

(2) Inkomba yokusebenza yeshidi lensimbi ye-silicon

A. Ukulahlekelwa kwensimbi ephansi. Inkomba ebaluleke kakhulu yekhwalithi, wonke amazwe emhlabeni ahlukanisa amamaki ngenani lokulahlekelwa kwensimbi. Lapho ukulahleka kwe-iron kuphansi, izinga eliphezulu liyakhuphuka futhi izinga eliphezulu.

B, amandla kazibuthe aphezulu. Ngaphansi komkhakha ofanayo kazibuthe, ishidi lensimbi ye-silicon enezinga eliphezulu lokungenisa kazibuthe lingatholakala, futhi umthamo nesisindo se-motor noma i-transformer iron core eyenziwe yilo kuncane kakhulu, okungahle konga ishidi lensimbi ye-silicon, intambo yethusi nezinto zokuvikela. .

C, i-coefficient yokupakisha iphezulu. Ingaphezulu leshidi lensimbi ye-silicon libushelelezi, liyisicaba futhi lifana ngokushuba, futhi i-coefficient yokupakisha ye-iron core iyathuthukiswa.

D. Ukubhoboza okuhle. Lokhu kubaluleke nakakhulu ekwenzeni ama-motor cores amancane, amancane.

E. Indawo engaphezulu inokunamathela okuhle kanye nokushisela efilimini yokuvikela.

F. Ukuguga kazibuthe G. Ishidi lensimbi ye-silicon lizolethwa ngemva kokucwiliswa nokucwiliswa.

(1) Ishidi lensimbi ye-silicon egoqelwe ngokushisayo ukuze isetshenziswe ugesi (GB5212-85) Ishidi lensimbi ye-silicon egoqwe ngokushisa ukuze lisetshenziswe ugesi lenziwe nge-ferrosilicon soft magnetic alloy elinokulahlekelwa yikhabhoni ephansi futhi liyashisa ligoqwe libe ishidi eliwugqinsi ngaphansi kuka-1mm. Ishidi lensimbi ye-silicon egoqwe ngokushisayo ukuze isetshenziswe ngogesi ibizwa nangokuthi ishidi lensimbi ye-silicone egoqiwe. Amashidi ensimbi ye-silicon egoqwe ngokushisayo angahlukaniswa abe yi-silicon ephansi (Si≤2.8%) kanye namashidi ensimbi e-high-silicon (Si≤4.8%) ngokuya ngokuqukethwe kwawo kwe-silicon.

(2) Ishidi lensimbi kagesi eligoqelwe ngokubanda (i-GB2521-88) lenziwe ngensimbi kagesi ye-silicon equkethe i-silicon engu-0.8% -4.8% futhi igoqwe ngokubanda. Amashidi ensimbi ye-silicon egoqwe ngokubanda ahlukaniswe abe izinhlobo ezimbili: imichilo yensimbi engenazo okusanhlamvu kanye ne-grain-oriented steel. Umugqa wensimbi kagesi ogoqeke obandayo unezici zendawo ebushelelezi, ukujiya okufanayo, i-coefficient yokunqwabelanisa okuphezulu, ukusebenza kahle kokubhoboza, futhi unokungenisa kukazibuthe okuphezulu nokulahlekelwa kwensimbi okuphansi kunomucu wensimbi kagesi eginqike ngokushisayo. Ukusebenzisa amapheshana abandayo esikhundleni samapheshana ashisayo ukwenza ama-motor noma ama-transformer kunganciphisa isisindo nevolumu yawo ngo-0% -25%.

Uma kusetshenziswa umugqa ogoqeke obandayo, ukusebenza kuba ngcono. Ukuyisebenzisa esikhundleni somugqa ogoqelwe oshisayo noma umugqa ogoqekayo osezingeni eliphansi kunganciphisa ukusetshenziswa kwamandla kwe-transformer ngo-45% -50%, futhi ukusebenza kokusebenza kwe-transformer kunokwethenjelwa kakhulu. Isetshenziselwa ukukhiqiza ama-motor nama-transformer. Ngokuvamile, amapheshana afakwe okusanhlamvu afakwe okusanhlamvu asetshenziswa njengesimo samamotho noma ama-welding transformers, njll.; Imichilo egoqekayo egxile okusanhlamvu isetshenziswa njengensimbi yeziguquli zamandla, ama-pulse transformers, ama-amplifiers kazibuthe, nokunye okunjalo. Ukucaciswa kwepuleti lensimbi nobukhulu: ukujiya okungu-0.35, 0.50, 0.65mm, ububanzi obungu-800-1000mm, nobude obungu-≤2.0m.

(3) Ishidi lensimbi ye-silicone egoqelwe ngokushisayo lezinto zasendlini (GBH46002-90) Ibanga leshidi lensimbi ye-silicon egoqwe ngokushisayo lezinto zasendlini limelelwa ngu-J (ekhaya) D (ugesi) R (i-hot rolling), okuyi-JDR. Inombolo engemva kwe-JDR inani lokulahlekelwa kwensimbi*100, futhi inombolo engemva komugqa ovundlile iwugqinsi lwepuleti lensimbi (mm)*100. Izidingo zokusebenza kwe-electromagnetic zamashidi ensimbi ye-silicon egoqwe ashisayo yezinto zikagesi zasendlini zingaba ngaphansi kancane, futhi inani elincane lokulahlekelwa kwensimbi (P15/50) ngu-5.40W/kg. Ivamise ukulethwa ngaphandle kokuwashwa. Amamotho ahlukene asetshenziswa ezintweni zasendlini ezahlukahlukene njengabalandeli bakagesi, imishini yokuwasha, izicoci ze-vacuum, ama-hood ahlukahlukene, njll.