CAH(11)-150B:

Basic properties:

A. Hydraulic single head feeding, unique way of push and pull of material feeding, global initiative (won national invention patent)

B. Precise center positioning, electric adjustable width structure

C. Can cut edge, stele, yoke, the narrowest can cut 30 mm, the shortest can be cut to 100 mm.

D. Use two layers discharge ways, automatic divide material sheet, feeding speed is 35 to 50 pieces per minute.

E. This line is design for the smaller power transformer core, efficiency was 2-3 times compare with ordinary cutting line.

F. New structure design, use servo swing cutting technology, can cut edge, yoke, stele, 45° parallel sides, 90° angles sheet, especially suitable for small iron core shear.

G. During the V punching can satisfied with transverse 3, 5, 7 step shear.

| NO. | NAME | QTY/td> | MANUFACTURER |

| 1 | CNC controller | 1 | TAIWAN |

| 2 | AC servo motor drive | 6 | TAIWAN |

| 3 | Servo motor | 6 | TAIWAN |

| 4 | Dedicated motion control module | 1 | CNC Controller |

| 5 | Hydraulic equipment | 1 | TAIWAN |

| 6 | Transducer | 2 | JAPAN TOSHIBA |

| 7 | Main low-voltage apparatus | 1 | SCHNEIDER |

| 8 | Whole machine installment | 1 | CANWIN |

1.Sheet shape:Side sheet, Yoke, Center sheet, 45 °Parallel plate, Partial center sheet, 90 ° right angle sheet, horizontal and vertical 3,5,7 step-lap.

2.Requirement for coil:

| No. | Name | Parameter |

| 1 | Coil ID | <1000mm |

| 2 | Coil weight | ≤1000KG |

| 3 | Width tolerance | ≤0.5mm/m |

| 4 | Burr tolerance | ≤0.02mm/m |

| 5 | S degree tolerance | 2000mm≤0.1mm/m |

| 6 | Edge wave degree | ≤0.5mm/m |

| 7 | Bending degree | ≤1mm/m |

3.Shearing precision:

| No. | Name | Parameter |

| 1 | Shearing thickness | 0.23mm--0.30mm |

| 2 | Shearing width | 30mm--160mm |

| 3 | Shearing length | 100mm-1200mm |

| 4 | Feeding speed | ≤120m/min |

| 5 | Length tolerance | ±0.2mm |

| 6 | Degree tolerance | ±0.025° |

| 7 | Shearing burr | Each grinding≤0.02mm |

| 8 | Machine total power | ≈8KW |

| 9 | Machine gas consumption | 0.2m³/min |

| 10 | Machine weight | ≈3ton |

4. Working condition: (1) Temperature not more than 40°C; (2) Voltage fluctuation 380V±10%; (3)Frequency 50Hz

FAQ

1.What can we do for you ?

We can provide you with power transformer manufacturing equipment and technical services for you to create a strong competitive transformer factory. We can provide you with special transformer OEM/ODM services. Even if you do not have the ability to produce, you can also go to pick up your order. We can provide you with all the high quality raw materials you need for your transformer plant production. Of course, the price must be very attractive!

2.How many years have your company made this kind of equipment?

We have 20 years of marketing experience and a 200,000 square foot modern manufacturing center.

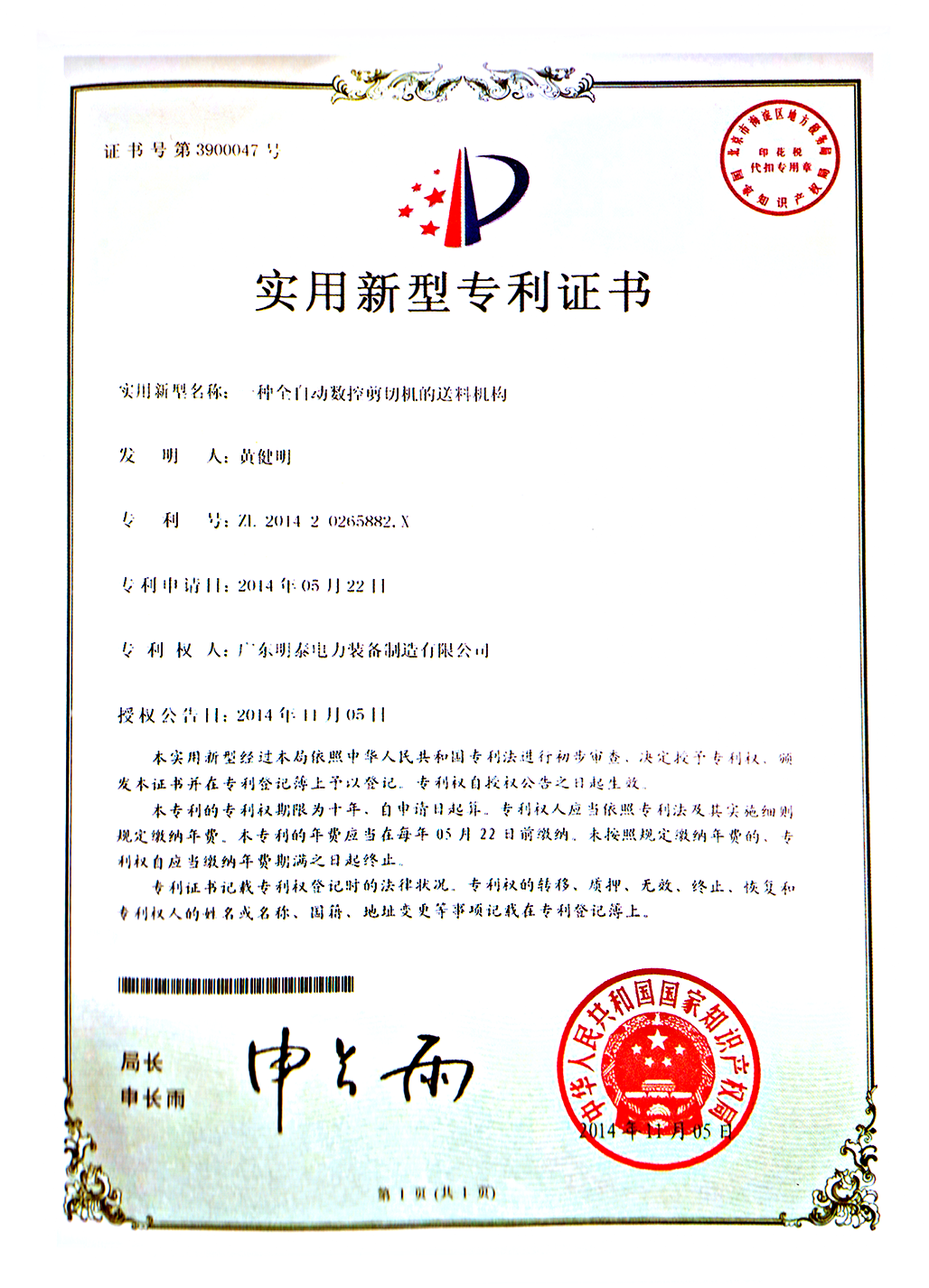

3.Which certificate do you have for your equipment?

We have owned 56 patents in fields of the international invention. ISO9001 / SO14001/ STL / ASTA / KEMA

4.Can you send your staff to install the equipment for us?

After - sales free to provide engineers on-site installation and debugging and professional technical training.Answer your technical or technical questions by phone or in writing.

5.Do you have any agent in our country?

CANWIN transform and upgrade traditional industries as an opportunity to deepen the " one belt and one road" strategic layout, deepen cooperation with foreign markets. in the form of cooperation and mutual benefit, set up the transformer manufacturing center and core processing base in the Middle East, India. Dubai. Vietnam. Thailand. etc.In the future, CANWIN will move towards the direction of intelligent equipment leader, making China a global reputation!

CONTACT US

LEAVE A MESSAGE

Please fill out and submit the form below, we will contact you in 48 hours, thank you!

RECOMMENDED

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.