Ulwakhiwo lomzimba wenguqu

Eli phepha lazisa ubukhulu becala ubume bomzimba we-transformer kwimiba emithathu: ingundoqo, ukujija kunye nelothe.

I.Ulwakhiwo olungundoqo lweTransformer

01 Indima yesilicon steel(Iron) core

Iinguqu zisekwe kumgaqo wokungeniswa kwe-electromagnetic, isekethe yamagnetic yindlela yokuguqula amandla ombane. I-Iron core iyona ngqungquthela yamagnetic ye-transformer, indima ephambili ngumagnetic. Iguqula amandla ombane wesekethe yokuqala ibe ngamandla emagnethi, kwaye ukusuka kumandla ombane ukuya kumandla ombane wesekethe yesibini.

Kwangaxeshanye, undoqo wentsimbi ngumathambo omatshini we-transformer, kwaye isixhobo esibambekayo sombindi wentsimbi asenzeli nje ukuba i-conductor magnetic ibe sisakhiwo esipheleleyo soomatshini, kodwa nayo ine-coil e-insulated kuyo, exhasa ukukhokela, kwaye phantse onke amacandelo ngaphakathi kwi-transformer. Ubunzima bentsimbi yentsimbi bukhulu kumacandelo e-transformer, kubalwa malunga ne-60% yesisindo esipheleleyo kwi-transformer eyomileyo, kunye ne-40% kwi-oyile-i-transformer.

02 Undoqo wentsimbi

Undoqo wentsimbi ubandakanya ikholamu yentsimbi kunye nejoka yentsimbi. Ikholamu engundoqo yentsimbi igqunywe ngamajiko-jiko kwaye idyokhwe yentsimbi idibanisa ikholamu engundoqo yentsimbi ukuze yenze isekethe yamagnetic evaliweyo.

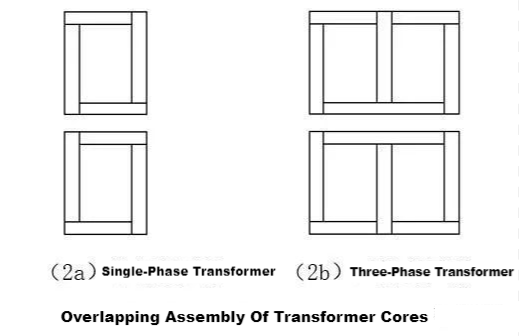

IKHIWANE. I-1A yinguqu yesigaba esinye, iFIG. I-1B sisiguquli esinezigaba ezithathu. Ulwakhiwo olungundoqo lwentsimbi lunokwahlulwa lube ngamacandelo amabini, C yinxalenye yekhoyili, eyaziwa ngokuba yintsika engundoqo. I-Y yinxalenye esetyenziselwa ukuvala i-circuit magnetic, ebizwa ngokuba yidyokhwe yentsimbi. I-transformer yesigaba esisodwa ineentsika ezimbini eziphambili, i-transformer yesigaba sesithathu ineentsika ezintathu ezingundoqo.

Ngenxa yokuba i-magnetic flux kumbindi we-iron transformer yi-alternating flux, ukuze kuncitshiswe ilahleko ye-eddy yangoku, i-iron core ye-iron ye-transformer yenziwe ngokubanzi kwi-chip yentsimbi eyenziwe nge-silicon sheet kunye nokumelana okuphezulu. Icwecwe lensimbi ye-silicon eyenziwe ngundoqo wentsimbi iqala isikwe kwimilo efunekayo kunye nobukhulu, oko kukuthi i-punching sheet, kwaye idibaniswe nephepha lokubhoboza ngendlela ethe kratya. Umzobo we-2A ubonisa ingundoqo yentsimbi ye-transformer yesigaba esisodwa. Umaleko ngamnye unamaphepha ama-4 angenanto. IKHIWANE. I-2b ibonisa undoqo wentsimbi yesiguquli sesigaba esithathu, umaleko ngamnye uqulunqwe ngamaqhekeza ama-6, kwaye indibaniselwano yamaqhekeza e-punch nganye yamaleko amabini isebenzisa iindlela ezahlukeneyo zolungiselelo ukuze igxadazele idibano yesekethe yemagnethi yomaleko ngamnye. Le ndlela yokudibanisa ibizwa ngokuba yindibano edibeneyo, enokuthi iphephe ukuhamba kwe-eddy yangoku phakathi kwamaphepha entsimbi. Kwaye ngenxa yokuba iileyile zidityanisiwe kwaye zifakwe, ii-fasteners ezimbalwa zingasetyenziselwa ukwenza isakhiwo sibe lula xa i-core icinezelwe. Xa zidityaniswa, iingceba zepunch ziqale ziwelene ukuze zenze umbindi wentsimbi, emva koko idyokhwe engezantsi iyabotshwa, amaqhekeza epunch edyokhwe engaphezulu ayatsalwa ukuze aveze umqolo wentsimbi, amajiko-jiko asele enziwe abekwe kwikholamu yombindi wentsimbi. ekugqibeleni kufakwa amaqhekeza epunch edyokhwe engaphezulu.

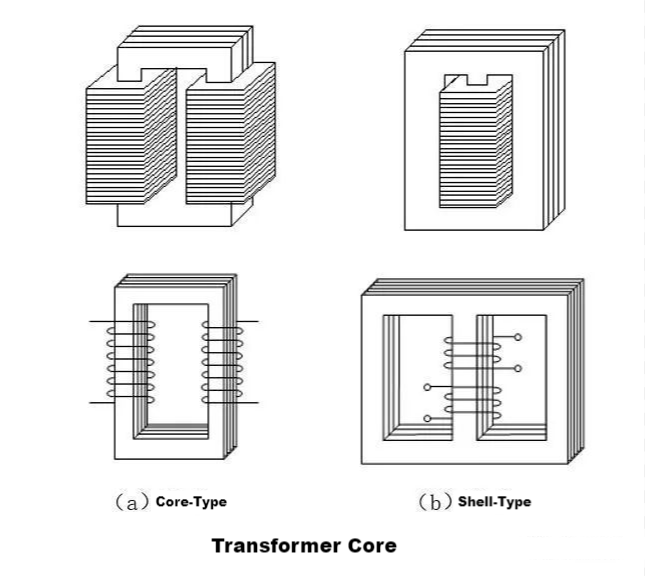

Ngokwendlela yokumisa kwi-core, i-transformer ihlulwe ibe yi-core kunye negobolondo uhlobo lwesibini. Umahluko ikakhulu kukusasazwa kwesekethe kazibuthe, iqokobhe isiguquli idyokhwe core engqongwe ikhoyili, undoqo transformer core uninzi ikhoyili, inxalenye kuphela ikhoyili ngaphandle idyokhwe yentsimbi, esetyenziselwa ukwenza loop magnetic.

03 Ukutshatyalaliswa kobushushu bombindi wentsimbi

Xa i-transformer isebenza ngokuqhelekileyo, i-iron core iya kuvelisa ubushushu ngenxa yelahleko yentsimbi, kwaye ubunzima obukhulu kunye nomthamo wentsimbi yentsimbi, ubushushu buya kuveliswa. Ukushisa kweoli ye-transformer ngaphezu kwe-95 degrees kulula ukuguga, ngoko ubushushu bomhlaba ongundoqo kufuneka ilawulwe ngaphantsi kweli qondo lobushushu kangangoko kunokwenzeka, nto leyo ifuna isakhiwo sokutshatyalaliswa kobushushu be-core ngokukhawuleza sikhuphe ubushushu be-core. Isakhiwo sokutshatyalaliswa kobushushu ikakhulu ukunyusa umgangatho wokutshatyalaliswa kobushushu kwi-core. Ukutshatyalaliswa kobushushu bombindi wentsimbi kubandakanya ukuchithwa kobushushu kumjelo we-oyile ongundoqo wentsimbi kunye nokutshatyalaliswa kobushushu bomzila womoya wentsimbi.

Kumthamo omkhulu we-oyile-i-oyile ye-oyile, iigrooves zihlala zibekwe phakathi kwe-laminates ye-iron core ukunyusa umphumo wokutshatyalaliswa kobushushu. I-oil groove yahlulwe yaba ziindidi ezimbini, enye ihambelana ne-silicon steel sheet kwaye enye ime nkqo kwiphepha lentsimbi, njengoko kubonisiwe kwi-FIG. 4. Olu lungiselelo lokugqibela lunomphumo ongcono wokutshatyalaliswa kobushushu, kodwa isakhiwo sinzima ngakumbi.

Ingundoqo yentsimbi ye-transformer eyomileyo ipholile emoyeni. Ukuze kuqinisekiswe ukuba ukushisa kwentsimbi yentsimbi akudluli ixabiso elivumelekileyo, i-air duct ivame ukufakwa kwikholamu yentsimbi kunye nejoka yensimbi.

04 Ingxolo yombindi wentsimbi

Abaguquli bavelisa ingxolo ngexesha lokusebenza. Umthombo wengxolo ye-transformer yi-magnetostriction ye-iron core silicon sheet yensimbi, okanye ingxolo ye-transformer core ibangelwa yi-magnetostriction. I-Magnetostriction ibhekiselele ekwandeni kobungakanani be-silicon sheet yentsimbi ecaleni komgca wokungeniswa kozibuthe xa undoqo wentsimbi uchwayitile. Ubungakanani beshiti lensimbi ye-silicon yancipha kwicala le-perpendicular kumgca wokungenisa magnetic, obizwa ngokuba yimagnetostriction. Ukongezelela, isakhiwo kunye nobukhulu bejometri yentsimbi yentsimbi, kunye nokucubungula kunye nokuvelisa iteknoloji yentsimbi yentsimbi iya kuba neqondo elithile lempembelelo kwinqanaba lengxolo.

Inqanaba lengxolo yombindi wentsimbi lingancitshiswa ngala manyathelo obugcisa alandelayo:

(1) Sebenzisa umgangatho ophezulu we-silicon sheet kunye nexabiso elincinci le-magnetostrictive ε.

(2) Ukunciphisa ukuxinana kwemagnethi kumbindi.

(3) Ukuphucula ubume bentsimbi.

(4) Khetha ubungakanani obufanelekileyo obungundoqo.

(5) Yamkela iteknoloji yokuqhubela phambili.

05 Ukugaywa kombindi wentsimbi

Ekusebenzeni okuqhelekileyo kwe-transformer, intsimi yombane eyenziwe phakathi kwee-windings zombane kunye nezikhokelo kunye netanki yeoli yintsimi yombane engalinganiyo, kunye nentsimbi yentsimbi kunye neengxenye zayo zetsimbi kule ndawo yombane. Ngenxa ye-electrostatic induction enokwenzeka ayifani, ukuze amandla okunqunyanyiswa kombindi wentsimbi kunye namacandelo ayo entsimbi ayifani, xa umahluko onokuthi ubekho phakathi kwamanqaku amabini anokwaphula ukugquma phakathi kwabo, ukukhutshwa kwentlantsi kuya kuveliswa. Oku kukhutshwa kungaphula ioli ye-transformer kwaye konakalise i-insulation eqinile. Ukuze ugweme oku, zombini ingundoqo kunye nezixhobo zayo zetsimbi kufuneka zisekelwe ngokuthembekileyo.

Undoqo kufuneka usekelwe kwindawo enye. Xa i-iron core okanye ezinye izinto zetsimbi zineengongoma ezimbini okanye ngaphezulu kweengongoma ezimbini zokumisa, indawo yomhlaba iya kwenza i-loop evaliweyo, ukubunjwa kokujikeleza, okukhoyo ngamanye amaxesha kunokuba kuphakamileyo kwishumi, kuya kubangela ukufudumeza kwendawo, ukukhokelela ekuqhekekeni kweoli, kunokwenza kwakhona i-fuse ye-grounding element, itshise i-iron core, ezi azivumelekanga. Ngoko ke, undoqo kufuneka usekelwe, kwaye usekelwe kancinci.

II. Ulwakhiwo olujikajikayo lweTransformer

Umsebenzi we-01 ukujija

Ukugquma yeyona ndawo isisiseko isiguquli, kukusekwa intsimi kazibuthe kunye nokuhanjiswa inxalenye yesekethe amandla ombane, ngokubanzi esongelwe ngocingo olukhuselayo lwephepha okanye inxeba aluminiyam yocingo, kwaye iseti kwikholam engundoqo ye-transformer. Undoqo we-transformer kufuneka ube namandla okwaneleyo okugquma, amandla omatshini kunye nokumelana nobushushu.

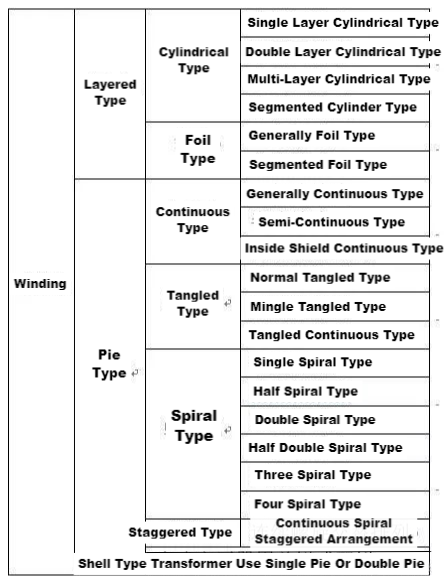

Uhlobo lokujija

Isakhiwo sokuguqula i-transformer sinokuhlulwa ngokubanzi kwiindidi ezimbini: isakhiwo somaleko kunye nesakhiwo sekhekhe. Ulwakhiwo lomaleko lubhekiselele ekubeni ujiko olujikayo ecaleni kwe-axis yalo lucwangciswe ngokuqhubekayo, ngokuqhelekileyo lusetyenziswa kwi-S8 kunye ne-S9 uthotho lwelahleko ephantsi yoguqulo lwamandla; Ulwakhiwo lwekhekhe lubhekisa kwinto yokuba ukujika kojiko kusenziwa ngokuqhubekayo kwikhekhe (icandelo) ecaleni kolwalathiso lweradial, kwaye emva koko iqulunqwe ngamaqebengwana amaninzi acwangciswe kwicala le-axial. Ngokuqhelekileyo isetyenziswa kwii-transformers ezinkulu nezingaphezulu-ezinkulu ezinamandla ombane aphezulu we-110kV nangaphezulu.

Ngokusisiseko, i-windings of power transformers eveliswe e-China yamkela ubume obunzulu. I-concentric winding ithetha ukuba i-windings ihlanganiswe ngaphandle kwekholomu engundoqo kunye nomgca we-cylindrical ofanayo nakweliphi na icandelo elinqamlezayo kwikholomu engundoqo. Kufuneka kubekho umsantsa othile wokugquma kunye nomjelo wokulahla ubushushu (ijelo le-oyile) phakathi kwamajiko ombane aphezulu naphantsi naphakathi kokujija kwamandla ombane aphantsi kunye nomqolo ongundoqo wentsimbi, owahlulwe ityhubhu yekhadibhodi egqunyiweyo. Umgama we-insulation uxhomekeke kwinqanaba le-voltage ye-winding kunye nokukhutshwa okufunwa ngumjelo wokutshatyalaliswa kobushushu. Xa i-low-voltage winding ifakwe ngaphakathi kufuphi nekholamu engundoqo, umgama ofunekayo wokugquma phakathi kwayo kunye nekholamu engundoqo incinci, ngoko ke ubungakanani bokuhamba bunokuncipha, kwaye ubukhulu be-transformer buyancipha.

I-transformer emithathu ejikelezayo isetyenziswa kakhulu kwinkqubo yamandla. Ukusebenzisa i-transformer enamavili amathathu ukudibanisa inkqubo yothumelo kunye ne-voltage ezintathu ezahlukeneyo kunoqoqosho ngakumbi, ihlala kumhlaba omncinci kwaye inokugcinwa kunye nokulawula ngokulula kunokusebenzisa iinguqu ezimbini eziqhelekileyo. Isigaba esithathu esijikajikayo isiguquli sikholisa ukusebenzisa iY-Y-△ uqhagamshelo, oko kukuthi, amajiko aphambili kunye nesibini ludibaniso lwe-Y, kwaye ujiko lwesithathu ngu △, njengoko kubonisiwe kuMfanekiso XX. △ uxhulumaniso ngokwalo luyi-loop evaliweyo, ngesigaba esifanayo se-harmonic yangoku, ukwenzela ukuba uxhulumaniso oluphambili lwe-Y, ukujikeleza okwesibini kungabonakali kumbane wesithathu we-harmonic. Ngale ndlela inika indawo engathathi hlangothi kumacala omabini aphambili kunye nesibini. Kwinkqubo yokuhanjiswa komgama omde, ukujika kwesithathu kunokudityaniswa nekhamera ye-synchronous ukuphucula amandla ombane womgca.

III. Ulwakhiwo olukhokelayo lweTransformer

01 Imathiriyeli ekhokelayo kunye nokuhlelwa

Transformer windings idityaniswe ngaphandle ukuya ekupheleni ekhokelayo yocingo kuthiwa ukukhokela, ngokusebenzisa ukhokelo ukuya lwangaphandle unikezelo lwamandla igalelo isiguquli, kodwa kwakhona ngokusebenzisa ukuhanjiswa okukhokelayo kwimveliso yamandla ombane ukusuka kwisiguquli ukuya ngaphandle.

Kukho ubukhulu becala ezi ndidi zilandelayo zezikhokelo:

(1) ucingo olulothe oludityaniswe nesiphelo socingo olujikajikayo kunye nesingxobo;

(2) ukudibanisa iintambo phakathi kweziphelo ezijikajikayo;

(3) ukucofa okujikelezayo kuqhagamshelwe nentambo yokucofa edityaniswe nesitshixo

Isixhobo esikhokelayo siqhelekile:

(1) Ibha yobhedu engenanto, umda osebenzayo: iklasi ye-10kV 6300kVA kunye ne-transformer engaphantsi;

(2) Ibha yobhedu engqukuva yephepha, umda osebenzayo: 10 ~ 35kV isiguquli somthamo omncinci;

(3) Ibha yobhedu engenanto, umda osebenzayo: 10kV kunye nangaphantsi kwee-low-voltage ezikhokelela ekujikeni;

(4) Iingcingo eziphothiweyo zeCopper, umda osebenzayo: onke amanqanaba ombane, ngakumbi i-110kV nangaphezulu kwelethe;

(5) Umbhobho wobhedu, umda wokusetyenziswa: 220kV kunye nelothe ye-transformer ngaphezulu.

Ukuze kuqinisekiswe umgama owaneleyo wokugquma, ukukhokela ngokhuni lwe-laminate, ukufakwa kwekhadibhodi, kufuneka kuhlangabezane neemfuno zokusebenza kombane, amandla omatshini, ukunyuka kobushushu. Ukukhethwa kwezikhokelo kukwasekelwe kumandla ombane kunye namandla omatshini, kunye nokunyuka kobushushu besiphaluka esifutshane kunye nobushushu bomthwalo wexesha elide lokunyusa le miba ukukhetha.

02 Ukudityaniswa kwelothe

Iifom zoqhagamshelo ezikhokelayo zeTransformer zezi: ukubrawuza, ukuwelda kwerhasi, ukuwelda koxinzelelo olubandayo kunye noqhagamshelo lwebholithi.

I-electrode ye-brazing iya kwenziwa nge-alloy copper ye-phosphor ukudibanisa phakathi kwe-winding outlet kunye ne-lead kunye naphakathi kwesikhokelo.

Ukuwelda kwerhasi kusetyenziselwa ukuwelda ucingo olukhokelela kwibha yobhedu kunye nentambo yokugqobhoza yecasing joint.

Uxinzelelo lwe-cold welding kukufaka iitheminali ezimbini ezidityaniswe ngumthonyama kwityhubhu yesinyithi, kwaye emva koko usebenzise i-mold ukucudisa ityhubhu yesinyithi, iitheminali ezimbini zicinezelwe kunye. I-welding yoxinzelelo olubandayo ayifuni ukufudumeza, i-welding ikhuselekile, akukho i-welding yobuxoki, kunye nokutshisa iintambo kunye nezinye iindawo zokugquma, umgangatho we-extrusion, ukomelela okulungileyo. Ke ngoko, i-welding yoxinzelelo olubandayo yeyona ndlela iphambili yonxibelelwano olukhokelela kwii-transformers ezinkulu.

Uqhagamshelo lwebholithi lusetyenziswa ikakhulu kucingo olukhokelayo oludityaniswe nomkhono wentonga yesikhokelo. Ucingo olukhokelayo lunokwahlulwa kwaye luyakwazi ukuhlawulela ukutenxa kobude besikhokelo. Ngesiqhelo, ulwakhiwo olugobileyo lwe-arc lunokukhululeka ukuba lwandise, olukwabizwa ngokuba ludibaniso oluthambileyo.

03 Ukuqiniswa kwesikhokelo

Ukuqinisekisa ukuba umgama we-insulation we-lead, kunye nokumelana nokungcangcazela kunye nefuthe lamandla ombane ngexesha lokusebenza kunye nesiphaluka esifutshane ngaphandle kokufuduswa kunye nokuguqulwa, iindawo zokugoba kufuneka zisetyenziswe ukuqinisa ukukhokela.

iindawo ezibambeneyo ngelothe kufuneka zibe namandla okwaneleyo koomatshini kunye namandla ombane, ngoko ke icandelo le-lead clamping yesakhiwo ngokubanzi lithatha isakhiwo senkxaso yamaplanga, iinxalenye ezibambezelayo kunye nenxalenye yentsimbi yomzimba ye-transformer zilungisiwe, ukuze kuphuculwe amandla oomatshini beebholiti zetsimbi ezikhoyo, kodwa phakathi koxinzelelo. iindawo kufuneka zilungiswe ngeebholiti ze-epoxy, kwaye kukho isixhobo esikhululekile. Ibhodi ye-insulation kufuneka yongezwe ukuze ibambe i-lead njenge-insulation eyongezelelweyo ukukhusela ilothe ekuxingeni.