Isakhiwo somzimba we-Transformer

Leli phepha lethula ngokuyinhloko ukwakheka komzimba we-transformer kusuka ezicini ezintathu: umnyombo, ukujikajika kanye nomthofu.

I.Transformer core structure

01 Indima ye-silicon steel(Iron) core

Ama-Transformer asekelwe kumgomo wokungeniswa kwe-electromagnetic, isifunda kazibuthe siyindlela yokuguqulwa kwamandla kagesi. I-iron core iyisiyingi esiyinhloko samagnetic se-transformer, indima eyinhloko yizibuthe. Iguqula amandla kagesi wesekethe eyinhloko ibe amandla kazibuthe, futhi asuke kumandla kazibuthe abe amandla kagesi wesekethe yesibili.

Ngesikhathi esifanayo, i-iron core iyi-skeleton yemishini ye-transformer, futhi idivayisi yokuqinisa i-iron core ayigcini nje ngokwenza i-conductor magnetic ibe isakhiwo esiphelele semishini, kodwa futhi inekhoyili e-insulated, esekela ukuhola, futhi. cishe zonke izingxenye ngaphakathi kwe-transformer. Isisindo se-iron core yisona esikhulu kunazo zonke ezingxenyeni ze-transformer, ezibalelwa cishe ku-60% wesisindo esiphelele ku-transformer eyomile, futhi cishe i-40% ku-transformer ecwiliswe ngamafutha.

02 Ifomu lensimbi ewumgogodla

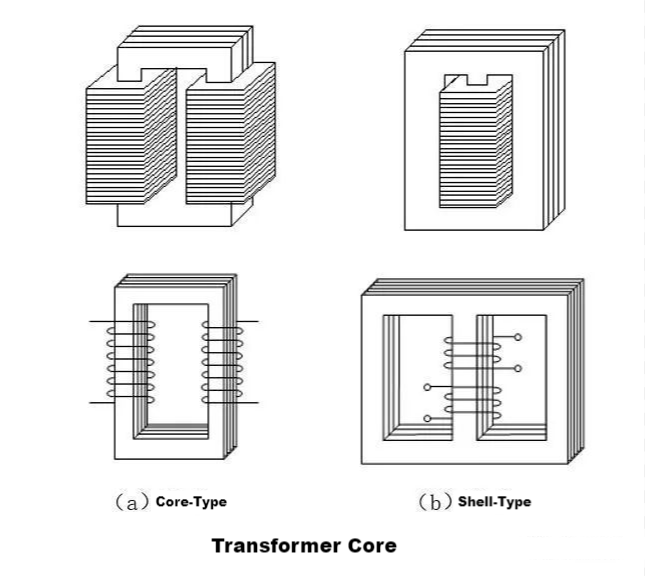

I-iron core iqukethe ikholomu yensimbi kanye nejoka lensimbi. Ikholomu ewumgogodla wensimbi imbozwe ama-windings futhi ijoka lensimbi lixhuma ikholomu ewumgogodla wensimbi ukuze kwakheke isekethe kazibuthe evaliwe.

I-FIG. I-1A iyisiguquli esinesigaba esisodwa, iFIG. I-1B iyisiguquli esinezigaba ezintathu. Isakhiwo sensimbi singahlukaniswa sibe izingxenye ezimbili, u-C uyingxenye yekhoyili, eyaziwa ngokuthi ikholomu eyinhloko. U-Y uyingxenye esetshenziselwa ukuvala umjikelezo kazibuthe, obizwa ngokuthi ijoka lensimbi. I-Single-phase transformer inezinsika ezimbili eziyinhloko, i-transformer yesigaba ezintathu inezinsika ezintathu eziyinhloko.

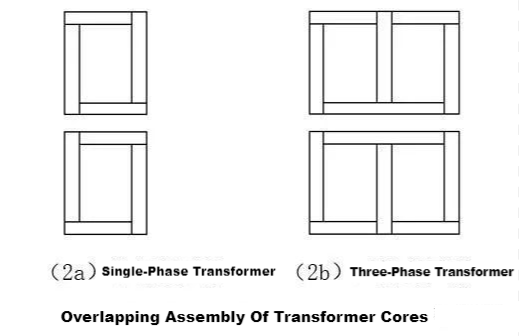

Ngenxa yokuthi i-magnetic flux ku-transformer iron core iyi-flux eshintshanayo, ukuze kuncishiswe ukulahlekelwa kwamanje kwe-eddy, i-transformer iron core ngokuvamile yenziwe ngosayizi othile we-chip iron eyenziwe ngeshidi lensimbi ye-silicon enokumelana okuphezulu. Ishidi lensimbi ye-silicon elakhiwe umgogodla wensimbi liqala ukusikwa libe yisimo nosayizi odingekayo, okuyishidi lokubhoboza, bese lihlanganiswa neshidi lokubhoboza ngendlela ehambisanayo. Umfanekiso 2A ubonisa umongo wensimbi we-transformer yesigaba esisodwa. Ungqimba ngalunye luqukethe amashidi angenalutho angu-4. I-FIG. I-2b ikhombisa umongo wensimbi we-transformer yezigaba ezintathu, ungqimba ngalunye lwakhiwe izingcezu eziyisi-6, futhi inhlanganisela yezingcezu ze-punch zezendlalelo ezimbili ngayinye isebenzisa izindlela ezihlukene zokuhlela ukuze kuntengantengise ukuhlangana kwesekethe kazibuthe yongqimba ngalunye. Le ndlela yokuhlanganisa ibizwa ngokuthi i-overlapping assembly, engagwema ukugeleza kwamanje phakathi kwamashidi ensimbi. Futhi ngenxa yokuthi izendlalelo zixhumene futhi zifakwe ngaphakathi, izibophelelo ezimbalwa zingasetshenziswa ukwenza isakhiwo sibe lula uma umgogodla ucindezelwa. Lapho kuhlanganiswa, izingcezu ze-punch ziqale zigoqene ukuze zakhe umgogodla wensimbi, bese ijoka elingaphansi liyaboshelwa, kukhishwe izingcezu zejoka eliphezulu ukuze kuvezwe ikholomu ewumgogodla wensimbi, amawindi asenziwe ngaphambilini abekwe phezu kwekholomu yensimbi, futhi ekugcineni kufakwa izingcezu ze-punch yejoka eliphezulu.

Ngokusho kokuhlelwa kokuvunguza ku-core, i-transformer ihlukaniswe yaba yi-core kanye negobolondo uhlobo lwesibili. Umehluko ikakhulukazi ukusatshalaliswa kazibuthe wesifunda, igobolondo transformer core ijoka ezungezwe ikhoyili, core transformer core iningi ikhoyili, ingxenye kuphela ikhoyili ngaphandle ijoka lensimbi, esetshenziswa ukwakha loop kazibuthe.

03 Ukukhipha ukushisa kwensimbi

Lapho i-transformer isebenza ngokujwayelekile, i-iron core izokhiqiza ukushisa ngenxa yokulahlekelwa kwensimbi, futhi isisindo esikhulu nevolumu ye-iron core, ukushisa okungaphezulu kuzokhiqizwa. Izinga lokushisa likawoyela we-Transformer ngaphezu kwama-degree angu-95 kulula ukuguga, ngakho-ke izinga lokushisa le-core surface kufanele lilawulwe ngaphansi kwalokhu kushisa ngangokunokwenzeka, okudinga isakhiwo sokushisa ukushisa kwengqikithi ukuze kukhishwe ngokushesha ukushisa komgogodla. Isakhiwo sokukhipha ukushisa ngokuyinhloko ukukhulisa indawo yokushisa yomgogodla. Ukukhishwa kokushisa komgogodla we-iron ikakhulukazi kuhlanganisa ukuchithwa kokushisa komgudu kawoyela oyingqikithi yensimbi kanye nokuhlakazwa kokushisa komzila womoya we-iron core.

Ngomthamo omkhulu wama-transformer acwiliswe uwoyela, ama-grooves kawoyela avame ukubekwa phakathi kwama-laminates of the iron core ukuze kuthuthukiswe umphumela wokukhipha ukushisa. I-oil groove ihlukaniswe yaba izinhlobo ezimbili, eyodwa ihambisana neshidi lensimbi ye-silicon kanti enye ime mpo eshidini lensimbi, njengoba kukhonjisiwe ku-FIG. 4. Ukuhlelwa kokugcina kunomphumela ongcono wokushisa ukushisa, kodwa isakhiwo siyinkimbinkimbi kakhulu.

Umnyombo wensimbi we-transformer owomile upholile emoyeni. Ukuze kuqinisekiswe ukuthi izinga lokushisa lensimbi alidluli inani elivumelekile, i-air duct ivame ukufakwa kukholomu yensimbi kanye nejoka lensimbi.

04 Umsindo wensimbi

Ama-transformer akhiqiza umsindo ngesikhathi sokusebenza. Umthombo womsindo we-transformer yi-magnetostriction ye-iron core silicon steel sheet, noma umsindo we-transformer core ngokuyisisekelo ubangelwa i-magnetostriction. I-Magnetostriction ibhekisela ekwandeni kosayizi weshidi lensimbi ye-silicon eduze komugqa wokungeniswa uzibuthe lapho ingqikithi yensimbi ijabulile. Ubukhulu beshidi lensimbi ye-silicon yehla endaweni eqondile ukuya kumugqa wokungenisa kazibuthe, obizwa ngokuthi i-magnetostriction. Ngaphezu kwalokho, isakhiwo kanye nosayizi wejometri we-iron core, kanye nokucubungula nokukhiqiza ubuchwepheshe be-iron core kuzoba nethonya elithile ezingeni lomsindo.

Izinga lomsindo we-iron core lingancishiswa ngezinyathelo zobuchwepheshe ezilandelayo:

(1) Sebenzisa ishidi lensimbi ye-silicon yekhwalithi ephezulu enenani elincane lika-magnetstrictive.

(2) Yehlisa ukuminyana kazibuthe okuguquguqukayo kwengqikithi.

(3) Thuthukisa ukwakheka komgogodla wensimbi.

(4) Khetha usayizi ozwakalayo owumongo.

(5) Yamukela ubuchwepheshe bokucubungula obusezingeni eliphezulu.

05 Ukugaywa kwensimbi

Ekusebenzeni okuvamile kwe-transformer, inkambu kagesi eyakhiwe phakathi kwama-windings afakwe ugesi kanye nokuhola futhi ithangi lamafutha liyinsimu kagesi engalingani, futhi insimbi yensimbi kanye nezingxenye zayo zensimbi zikule nsimu kagesi. Ngenxa yamandla okungeniswa kwe-electrostatic akufani, ukuze amandla okumiswa kwensimbi eyinhloko kanye nezingxenye zawo zensimbi akufani, lapho umehluko ongaba khona phakathi kwamaphuzu amabili ungabhidliza ukufakwa phakathi kwawo, ukukhishwa kwenhlansi kuzokwenziwa. Lokhu kuphuma kungabhidliza uwoyela we-transformer futhi kulimaze ukufakwa okuqinile. Ukuze ugweme lokhu, kokubili okuphakathi kanye nezingxenye zayo zensimbi kufanele kusekelwe ngokuthembekile.

Umgogodla kufanele usekelwe endaweni eyodwa. Lapho umnyombo wensimbi noma ezinye izingxenye zensimbi zinamaphuzu amabili noma amaphuzu angaphezu kwamabili okusuka phansi, indawo ephansi izokwakha iluphu evaliwe, ukwakheka kokujikeleza, okwamanje ngezinye izikhathi kungaba phezulu ngamashumi e-an, kuzodala ukushisa kwendawo, kuholela ekuwohlokeni kwamafutha, kungase futhi kwenze i-grounding element fuse, kushise i-iron core, lezi azivunyelwe. Ngakho-ke, umgogodla kufanele ubekwe phansi, futhi usekelwe kancane.

II. Isakhiwo sokuguqula i-Transformer

Umsebenzi we-01 wokujika

Ukuvunguza kuyingxenye eyisisekelo kakhulu ye-transformer, ukusungulwa kwamandla kazibuthe kanye nokudluliswa kwengxenye yesifunda samandla kagesi, ngokuvamile esongwe ngocingo lwethusi oluvikelayo lwephepha noma inxeba locingo lwe-aluminium, futhi lubekwe kukholamu eyinhloko ye-transformer. Umgogodla we-transformer kufanele ube namandla okwanele okufaka amandla, amandla omshini nokumelana nokushisa.

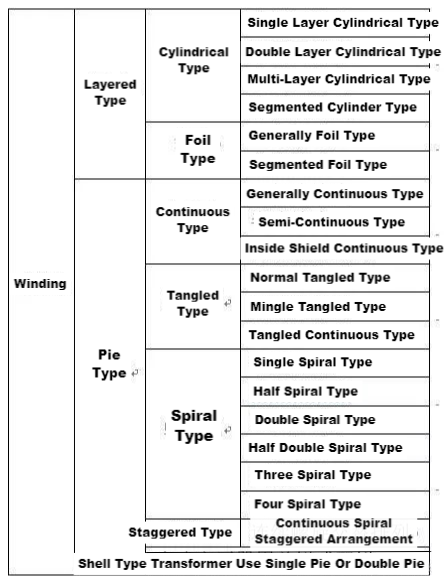

Uhlobo lokusonta

Isakhiwo sokuguqula i-Transformer singahlukaniswa ngokujwayelekile zibe izigaba ezimbili: isakhiwo sesendlalelo kanye nesakhiwo sekhekhe. Isakhiwo sesendlalelo sisho ukuthi ukuphenduka okuphendukayo ku-axis yayo kuhlelwe ngokuqhubekayo, ngokuvamile kusetshenziswa ku-S8 kanye nochungechunge lwe-S9 lwama-transformer amandla alahlekelwa kancane; Isakhiwo sekhekhe sibhekisela ekutheni ukuphenduka kokusonta kuqhutshwa ngokuqhubekayo ibe ikhekhe (ingxenye) eduze nokuqondisa kwayo kwe-radial, bese ihlanganiswa namaqebelengwane amaningi ahlelwe ngokuhambisana ne-axial direction. Ngokuvamile isetshenziswa kuma-transformer amakhulu nangaphezulu ane-voltage ephezulu engu-110kV nangaphezulu.

Ngokuyisisekelo, ama-windings ama-transformer amandla akhiqizwa e-China asebenzisa ukwakheka okugxile. Ukusonteka okugxile kusho ukuthi amajika asongwe ngaphandle kwekholomu ewumgogodla ngomugqa wesilinda ofanayo kunoma iyiphi ingxenye ephambanayo yekholomu ewumgogodla. Kumelwe kube negebe elithile lokwahlukanisa kanye neshaneli yokuqothula ukushisa (umzila kawoyela) phakathi kwamajika kagesi aphezulu naphansi naphakathi kwama-winding voltage aphansi kanye nekholomu yensimbi ewumgogodla, ehlukaniswe ngamashubhu ekhadibhodi afakwe ngci. Ibanga le-insulation lincike ezingeni le-voltage le-winding kanye nemvume edingwa isiteshi sokukhipha ukushisa. Lapho i-low-voltage winding ifakwe ngaphakathi eduze kwekholomu eyinhloko, ibanga elidingekayo lokuhlukanisa phakathi kwalo nekholomu eyinhloko lincane kakhulu, ngakho-ke ubukhulu bokuhamba bungancishiswa, futhi ubukhulu be-transformer buyancipha.

I-transformer emithathu emazombezombe isetshenziswa kakhulu ohlelweni lwamandla. Ukusebenzisa i-transformer enamawindi amathathu ukuxhuma isistimu yokudlulisa ngama-voltage amathathu ahlukene ukonga kakhulu, kuthatha indawo encane futhi inokugcinwa nokuphatha okulula kunokusebenzisa ama-transformer amabili ajwayelekile. I-transformer yezigaba ezintathu ezimazombezombe ivamise ukusebenzisa ukuxhumana kwe-Y-Y-△, okungukuthi, ama-winding ayisisekelo nawesibili uwuxhumano luka-Y, kanti okokujika kwesithathu ngu-△, njengoba kuboniswe kuMfanekiso XX. △ uxhumano ngokwalo luyiluphu evaliwe, ngesigaba esifanayo se-harmonic yamanje yesithathu, ukuze uxhumano oluyinhloko lwe-Y, ukujika kwesibili kungaveli ku-voltage yesithathu ye-harmonic. Ngale ndlela inikeza iphuzu elingathathi hlangothi kuzo zombili izinhlangothi eziyisisekelo nesesibili. Kuhlelo lokudlulisa ibanga elide, ukujikajika kwesithathu kungaphinda kuxhunywe ngekhamera ehambisanayo ukuze kuthuthukiswe isici samandla solayini.

III. Isakhiwo sokuhola se-Transformer

01 Izinto eziholayo kanye nokuhlukaniswa

I-Transformer windings ixhunywe ngaphandle ekupheleni okuhamba phambili kocingo kubizwa ngokuthi i-lead, ngokusebenzisa i-lead kuya ku-transformer yangaphandle yamandla okufaka amandla okufaka amandla, kodwa futhi ngokudluliswa kokuhola ekuphumeni kwamandla kagesi kusuka ku-transformer kuya ngaphandle.

Kukhona ikakhulukazi izinhlobo ezilandelayo zokuhola:

(1) intambo yomthofu exhunywe ekugcineni kocingo oluvunguzayo kanye ne-casing;

(2) ukuxhuma imikhondo phakathi kweziphetho ezimazombezombe;

(3) ukuchofoza okusongayo kuxhunywe nomthofu wokucofa oxhunywe neswishi

Izinto eziholayo ngokuvamile ziyi:

(1) Ibha yethusi engenalutho, ububanzi obusebenzayo: ikilasi le-10kV 6300kVA nangaphansi kwe-transformer;

(2) Ibha yethusi esongwe ngephepha, ububanzi obusebenzayo: 10 ~ 35kV isiguquli samandla amancane;

(3) Ibha yethusi engenalutho, ububanzi obusebenzayo: 10kV nangaphansi kwemibhobo evunguzayo ene-voltage ephansi;

(4) Izintambo ezinezintambo zethusi, ububanzi obusebenzayo: wonke amazinga kagesi, ikakhulukazi i-110kV nangaphezulu komthofu;

(5) Ipayipi lethusi, ububanzi bokusebenza: 220kV nangaphezulu komthofu we-transformer.

Ukuze kuqinisekiswe ibanga elanele lokuhlukanisa, ukuhola ngokhuni lwe-laminate, ukufakwa kwamakhadibhodi, kufanele kuhlangabezane nezidingo zokusebenza kukagesi, amandla emishini, ukunyuka kwezinga lokushisa. Ukukhethwa kwemikhondo kusekelwe futhi emandleni enkundla kagesi namandla emishini, kanye nokukhuphuka kwezinga lokushisa kwesifunda esifushane kanye nezinga lokushisa lomthwalo wesikhathi eside likhuphuka lezi zici okufanele zikhethwe.

02 Ukuxhumana komthofu

Amafomu okuxhumana okuhola i-Transformer yilawa: i-brazing, i-gas welding, i-cold pressure welding kanye nokuxhumeka kwebhawodi.

I-electrode ye-brazing izokwenziwa nge-phosphor copper alloy ukuze kuxhunywe i-outlet emazombezombe kanye nomthofu naphakathi kwemikhondo.

Ukushisela igesi kusetshenziselwa ukushisela ucingo oluholayo lwebha yethusi kanye nejoyinti yokubhoboza ikhebula lebhokisi.

I-Cold pressure welding iwukufaka amatheminali amabili axhunywe umthofu eshubhuni lensimbi, bese usebenzisa isikhunta ukuze ucindezele ishubhu lensimbi, amatheminali amabili acindezelwe ndawonye. I-Cold pressure welding ayidingi ukufudumeza, i-welding iphephile ngokuqhathaniswa, ayikho i-welding yamanga, nokushiswa kwemikhondo nezinye izingxenye zokufakelwa, ikhwalithi ye-extrusion, amandla aqinile. Ngakho-ke, i-cold pressure welding iyindlela eyinhloko yokuxhuma okuholela kuma-transformers amakhulu.

Uxhumano lwebhawodi lusetshenziswa kakhulu ocingweni oluholayo oluxhunywe nomkhono wenduku yomhlahlandlela. Intambo eholayo ingahlakazwa futhi inganxephezela ukuchezuka kobude bokuhola. Imvamisa, ukwakheka komthofu we-arc egobile kungaba mahhala ukunwetshwa, okwaziwa nangokuthi ukuxhumana okuthambile.

03 Ukuqiniswa komthofu

Ukuze kuqinisekiswe ibanga le-insulation lomthofu, futhi umelane nokudlidliza kanye nomthelela wamandla kagesi ngesikhathi sokusebenza kanye nokujikeleza okufushane ngaphandle kokugudluzwa kanye nokuguqulwa, izingxenye zokubopha kufanele zisetshenziselwe ukuqinisa umthofu.

Izingxenye zokubopha umthofu kufanele zibe namandla okusebenza anele namandla kagesi, ngakho-ke ukwakheka kwengxenye ye-lead clamping ngokuvamile kuthatha isakhiwo sokusekela izinkuni, izingxenye zokubopha kanye nezingxenye zensimbi zomzimba we-transformer zihleliwe, ukuze kuthuthukiswe amandla omshini wamabhawodi ensimbi atholakalayo, kodwa phakathi kwe-clamping. izingxenye kufanele zilungiswe ngama-epoxy bolts, futhi kukhona idivayisi evulekile. Ibhodi le-insulation kufanele lifakwe ukuze libambe umthofu njengento eyengeziwe yokuvikela ukuvimbela ukuminyana komthofu.