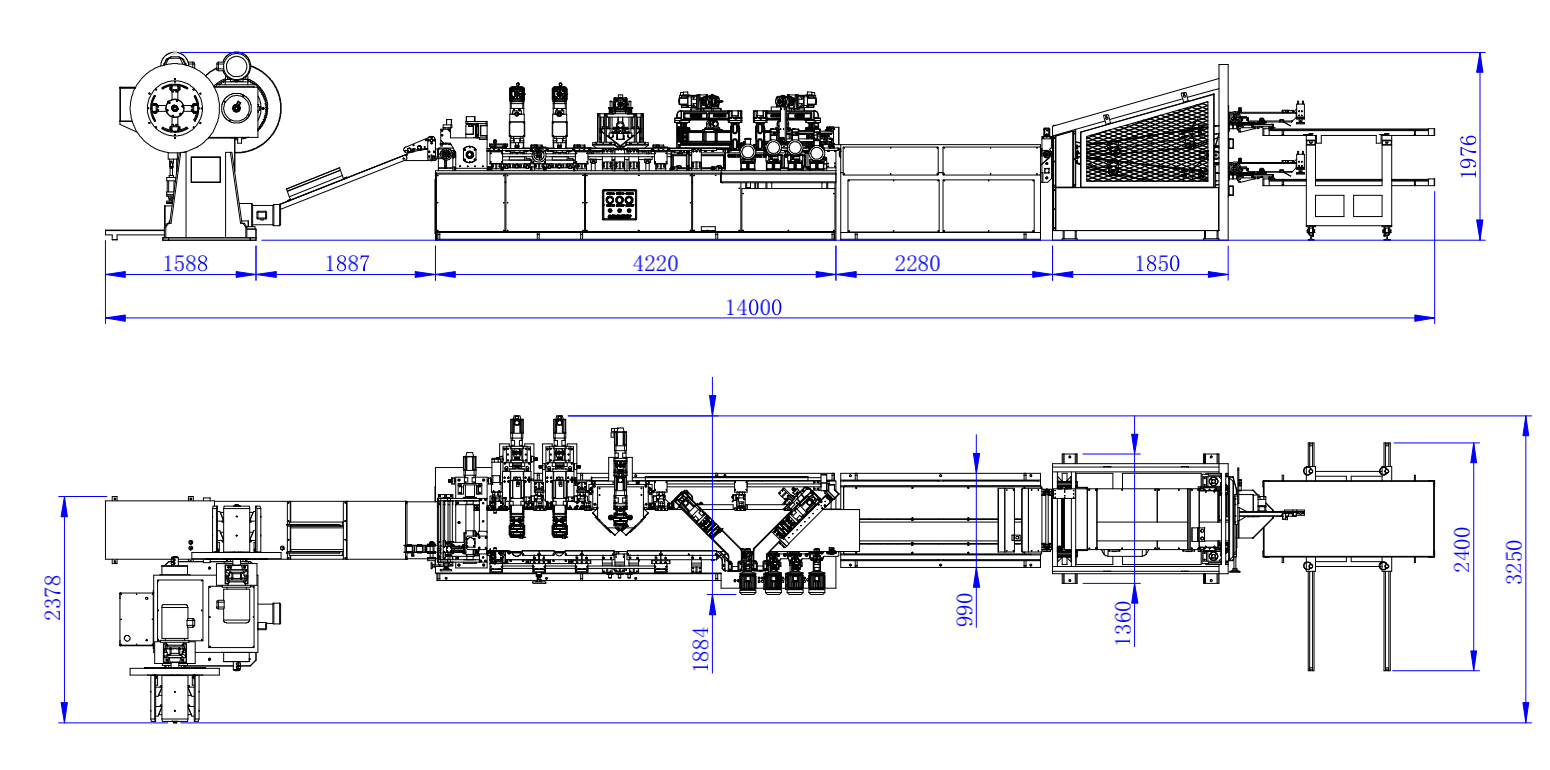

CAH(23)-400DO: The cut-to-length-line is a special equipment for the production of transformer core, is our latest generation of cross shear line. This production line is used for shearing, O punching and V notch of transformer core sheet.

The special point of this line is that two O punch and one V notch can work for York-sheet with two floor stacking;Can produce transformer core pieces with 3, 5, 7 steps in vertical direction and 3, 5, 7 steps in horizontal direction.

After the coil material of silicon steel sheet is punched and cut into certain shape and size by this production line, the classification and finishing work is completed at the end of the production line, and it is automatically stacked into 2-4 columns and used for the core assembly.

This production line adopts advanced control system to ensure the accurate and stable operation of the production line. Embedded operating terminal can complete parameter setting quickly and conveniently.

Application: This machine is special for transformer lamination manufacturing.

◪ The machine body is welded with high quality steel and with casting punching and shear component. The installation surface is made of thickened steel plate. The structure is solid and firm, and the hidden trouble of deformation is eliminated by heat treatment.

◪ The punching and shearing machine is mainly made of high grade castings, which will never be deformed, which is conducive to ensuring the shearing accuracy and improving the service life of the tool; At the same time effectively eliminate the impact shear chatter and noise.

◪ Optimized feeding and feeding system, stable and reliable performance, to ensure that the silicon steel sheet can be delivered at high speed.

◪ The punching and shearing mechanism is driven by high response servo motor, which is accurate and efficient.

◪ The punching and shear is made of high quality hard alloy, with long service life and little wear.

◪ Siemens electric control system is adopted to realize precise determination of long shear, full closed loop control, online detection and automatic fine adjustment.

◪ The width adjusting mechanism is driven by servo motor and controlled by computer to realize automatic width adjusting.

Front and rear feeder is composed of upper and lower feeding roller and measuring roller, feeding drive adopts German Siemens Simotion motion control system. This equipment adopts the most advanced center positioning servo push and pull material mechanism design; The feeding roller is made of polyurethane material, encoder measuring length and servo closed-loop control, the normal feeding speed is 0-180 m/min, the highest feeding speed is 240 m/min. The front feeder drives the role of pushing material, and the rear feeder drives the role of pulling material. The two feeder can work synchronously to keep the material in the channel straight in motion.

This machine has two sets of O-Punch and V-Punch, one set of O-Punch, they are driven by servo motor can realize the lateral movement step, two sets of V Notch face to face installed on both sides of O punch, driven by servo motor can realize the longitudinal step movement;

The design can cut the yoke and edge separately, saving materials for customers.

Two sets of shear sections are installed on a fixed plate at 45 degrees and 135 degrees, The fixed plate is installed on the sliding block of the movable parallel guide rail, and the fixed plate can move horizontally through the servo motor drive;

The shears section includes: +45° shears and 135°shears, transverse slide table and discharging roller. The structure of the two groups of shearing machines are made of casting. Shearing is driven by Siemens servo motor with high efficiency and low noise.

The tool (die) adopts hard alloy cutting tool, each grinding time use more than 1 million times. With depth adjustment mechanism, so that the tool can be adjusted after wear.

The whole line adopts central positioning and centralized width adjustment to adapt to different widths of sheet material transmission.

Encoder position feedback and position indicator position display. The width adjusting mechanism adopts ball screw drive to achieve the centralized width adjusting linkage of the whole line. The width adjustment device is also equipped with a blocking alarm device to realize the suspension of the whole machine when the material is arched.

FAQ

1.What can we do for you ?

We can provide you with power transformer manufacturing equipment and technical services for you to create a strong competitive transformer factory. We can provide you with special transformer OEM/ODM services. Even if you do not have the ability to produce, you can also go to pick up your order. We can provide you with all the high quality raw materials you need for your transformer plant production. Of course, the price must be very attractive!

2.How many years have your company made this kind of equipment?

We have 20 years of marketing experience and a 200,000 square foot modern manufacturing center.

3.Which certificate do you have for your equipment?

We have owned 56 patents in fields of the international invention. ISO9001 / SO14001/ STL / ASTA / KEMA

4.Can you send your staff to install the equipment for us?

After - sales free to provide engineers on-site installation and debugging and professional technical training.Answer your technical or technical questions by phone or in writing.

5.Do you have any agent in our country?

CANWIN transform and upgrade traditional industries as an opportunity to deepen the " one belt and one road" strategic layout, deepen cooperation with foreign markets. in the form of cooperation and mutual benefit, set up the transformer manufacturing center and core processing base in the Middle East, India. Dubai. Vietnam. Thailand. etc.In the future, CANWIN will move towards the direction of intelligent equipment leader, making China a global reputation!

CONTACT US

LEAVE A MESSAGE

Please fill out and submit the form below, we will contact you in 48 hours, thank you!

RECOMMENDED

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.