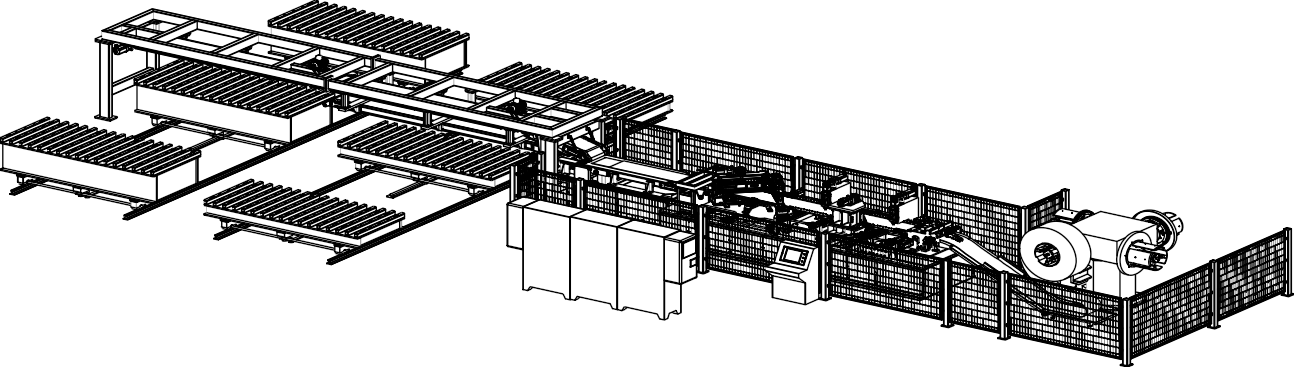

CAH(23)-400LA: The cut-to-length-line is a special equipment for the production of transformer core, is our latest generation of cross shear line. This production line is used for shearing, O punching and V notch of transformer core sheet.

The special point of this line is that two O punch and one V notch can work at the same time to produce transformer core pieces with 3, 5, 7 steps in vertical direction and 3, 5, 7 steps in horizontal direction.

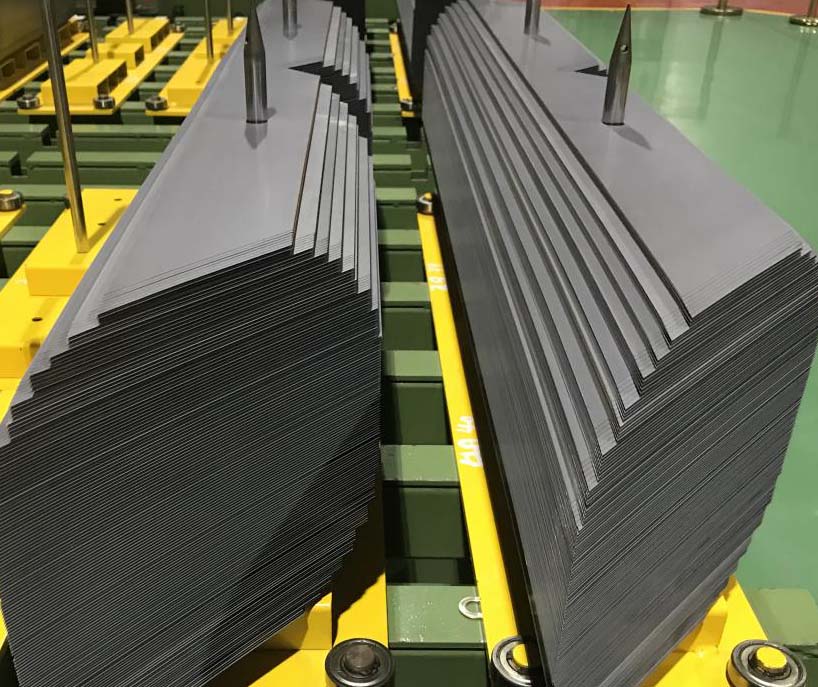

After the coil material of silicon steel sheet is punched and cut into certain shape and size by this production line, the classification and finishing work is completed at the end of the production line, and it is automatically stacked into 20 columns and used for the silicon steel lamination core assembly.

This production line adopts advanced control system to ensure the accurate and stable operation of the production line. Embedded operating terminal can complete parameter setting quickly and conveniently.

Application: This machine is special for silicon steel transformer laminations manufacturing.

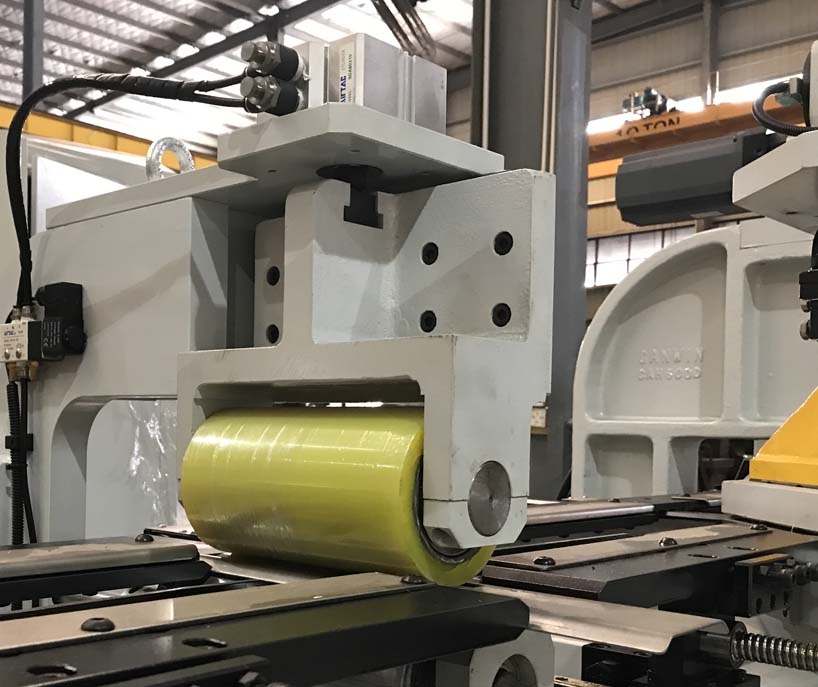

◪ The machine body is welded with high quality steel and with casting punching and shear component. The installation surface is made of thickened steel plate. The structure is solid and firm, and the hidden trouble of deformation is eliminated by heat treatment.

◪ The punching and shearing machine is mainly made of high grade castings, which will never be deformed, which is conducive to ensuring the shearing accuracy and improving the service life of the tool; At the same time effectively eliminate the impact shear chatter and noise.

◪ Optimized feeding and feeding system, stable and reliable performance, to ensure that the silicon steel laminations can be delivered at high speed.

◪ The punching and shearing mechanism is driven by high response servo motor, which is accurate and efficient.

◪ The punching and shear is made of high quality hard alloy, with long service life and little wear.

◪ Siemens electric control system is adopted to realize precise determination of long shear, full closed loop control, online detection and automatic fine adjustment.

◪ The width adjusting mechanism is driven by servo motor and controlled by computer to realize automatic width adjusting.

| Parameter | CAH(23)-400LA | CAH(23)-600LA | CAH(23)-800LA |

| Wdith of sheet (mm) | 80-400 | 80-600 | 80-800 |

| Length of sheet (mm) | 560-2500 | 560-3500 | 560-4500 |

| Thickness of sheet (mm) | 0.18-0.35 | ||

| Feeding speed (m/min) | 0-240m/min | ||

| Cutting burr (mm) | ≤0.02 | ||

| Accuracy of cutting angle | ±0.01 | ||

Electrical steel laminations are constituent parts of every electric motor. They are produced in a rapid-stamping process by forming electrical steel with a thickness of between 0.25 and 1 mm. We produce rotor and stator laminations and assembled stator and rotor stacks.

Electrical steels typically range in thickness from 0.20 mm to 0.65 mm, depending on the manufacturing cost and the complexity of handling for core building.

As part of the production process, we need rapid-stamping tools that we design, manufacture, and assemble ourselves. These tools allow us to produce the laminations with precise geometrical accuracy.

A rapid stamping process is used to produce electrical steel laminations for orders of large batches, using the latest technologies and modern trends. We use single notching technology and laser cutting for some projects in order to produce test samples and smaller batches of laminations optimally.

Areas of product application

Laminations of electrical steel are used in various segments of the automotive industry, including drive motors for electric and hybrid vehicles, pumps, heating, cooling, and air conditioning systems for vehicles.

Developed, constructed, produced, and assembled by Canwin electrical lamination manufacturers, rapid-stamping tools ensure high quality and reduce the time from initial contact to large-scale production. With the know-how and innovativeness of the Centre’s top experts, the Tool Components Competence Centre supports the business unit's successful growth with state-of-the-art technologies and machines to process materials.

FAQ

1.What can we do for you ?

We can provide you with power transformer manufacturing equipment and technical services for you to create a strong competitive transformer factory. We can provide you with special transformer OEM/ODM services. Even if you do not have the ability to produce, you can also go to pick up your order. We can provide you with all the high quality raw materials you need for your transformer plant production. Of course, the price must be very attractive!

2.How many years have your company made this kind of equipment?

We have 20 years of marketing experience and a 200,000 square foot modern manufacturing center.

3.Which certificate do you have for your equipment?

We have owned 56 patents in fields of the international invention. ISO9001 / SO14001/ STL / ASTA / KEMA

4.Can you send your staff to install the equipment for us?

After - sales free to provide engineers on-site installation and debugging and professional technical training.Answer your technical or technical questions by phone or in writing.

5.Do you have any agent in our country?

CANWIN transform and upgrade traditional industries as an opportunity to deepen the " one belt and one road" strategic layout, deepen cooperation with foreign markets. in the form of cooperation and mutual benefit, set up the transformer manufacturing center and core processing base in the Middle East, India. Dubai. Vietnam. Thailand. etc.In the future, CANWIN will move towards the direction of intelligent equipment leader, making China a global reputation!

CONTACT US

LEAVE A MESSAGE

Please fill out and submit the form below, we will contact you in 48 hours, thank you!

RECOMMENDED

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.