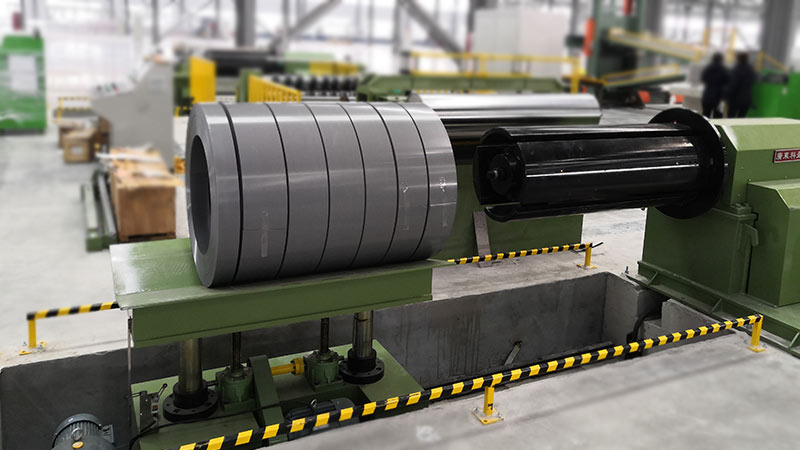

CAZJ-1250B: CNC precision slitting line is mainly used for strip silicon steel sheet coils processed by high-speed precision, mainly consist of:

1. Motor Decoiler: 1 set

2. Decoiler trolley: (Assist operation platform): 1 set

3. Guard rail/shaft: 2 sets

4.1250 type rolling coil slitting machine(with 07set alloy cutter ): 1 set

5.Material photoelectric detection device: 2 set

6.Pneumatic tensioner: 1 set

7. Motor Recoiler: 1 set

8.Electric trolley: 1 set

9.Pneumatic system:1 set

10.Electrical control system: 1 set

a. Hydraulic operation to lift arm to support the opening end of decoiler. It will provide stable decoiler movement and reduce load pressure.

b. Shaft OD: About Φ460-520mm

c. Axis core structure: Composed of four sets of wedge block, use the advanced non-welding structure

d. Braking device: Motor braking system (Active feeding ways)

e. Mechanical structure: Processed by steel plate and steel welding.

a. Rotary Slitting Shaft can turn forward and backward, slitter width can be adjusted according to the alloy cutter Drive by AC motor.

b. Cutting ways: Circular knife type.

c. Mechanical structure:

a. Shaft material: SCM440

b. Shaft diameter: Φ 120mm up and down each one, no key structure.

c. Knife shaft adjustment: the upper and lower shaft fixed, unilateral adjustment, control accuracy effectively.

d. Knife shaft fastening: up and down knife shaft adopts double nut as axial fastening.

d. Cutter and rubber gasket: each seven sets

e. The slitter is driven by 1.5KW AC motor, using the reduction gear, single output.

a. Each strip is separated by separators, and tensions will be applied before re-coiling. The tension on strips will enable proper coiling and prevent collapse after removing from re-coiler.

b. Tensioner equipped with three groups of cylinder pressure institutions

c. Tensions can be adjusted according to different type of slitting material. Structure is flat felt type.

d. Especially for silicon steel slitting line design pressure burr device, manual synchronization control

Slit the steel and received, manual to put the slitted coil to trolley. Recoiler driven by servo motor to rotate, equipped with auxiliary type manual work station to control the forward and inversion. Equipped with manual wrench, manual adjusting material support plate tight and narrow.

Mechanical structure:a. Strip coiler: composed of motor, reducer and the supporting plate.

b. Coiler ID: Φ460-520 mm

c. Plate expand and narrow: with a wrench, using manual to regulate expand and narrow state, has a seam type structure.

d. Axis core structure: composed of six set of wedge block, use the advanced non-welding structure.

e. Coiler OD:Φ1200 mm (Max.)

f. Slit coil weight: About 5T (Max.)

g. Coiling way: overwind

a. Equipped with two sets of photoelectric detection device, which located in the buffer pit walls which front the rolling shear and tensioner.

b. Photoelectric detection device is length measurement and material distance measuring, to reach automatic feed and automatic receiving function.

c. Two sets of photoelectric detection device contains six photoelectric switches.

a. a.PLC control system, effectively realize automatic feeding, automatic roll cutting, automatic receive material.

b. Human touch screen operation system, can be set freely roll cutting speed, material cutting length.

A.Mother Coils Specifications For This Slitting Line:

| The slitting is design for slitting of CRGO & CRNGO Electrical Steel Coils | |

| Material tensile strength | σb≤440Mpa, σ0.2≤280Mpa |

| Material thickness | 0.23-0.5mm |

| Coil width | 80-1250 mm (max.) |

| Coil inside-diameter | Ф460-Ф520mm |

| The coil outside-diameter | 1200mm (max) |

| Coil weigh | About 5T (Max.) |

B.Finished Product / Slit Coils Specification:

| Coil inside-diameter | Ф508mm ±20 |

| Coil outside-diameter | 1200mm (max.) |

| Coil weight | About 5T (Max.) |

| Width tolerance | ±0.20 mm (when new cutter shearing is 0.05mm) |

| Slitting width | 80mm |

| Number of strips | 10strips (when thickness less than 0.5mm |

| Clearance between slitting Cutters and spacers | ≤0.005 mm, clearance between slitting Cutters inside-diameter and main slitting shaft outside-diameter: ≤0.05 mm. This is to ensure proper slitting quality of coils. |

C.Equipment Specification with Slitting Lines:

| Electric power supply | 380V/50 Hz/3PH |

| Electric power capacity | About 25KW |

| Slitting speed | 0-150m/min |

| Slitting mechanism | Variable frequency drive |

| Re-coiler director | Underwind |

| Control mode | PLC control, automatic speed track feeding |

| Floor area | About 10m length x 5m width |

| The slitting line direction | From left to right (Facing operating station, from left upload to right discharge) |

| Machine colour | Green (Standard) |

Installation Requirement:

a. Canwin will provide machine floor-plan after signing of contract.

b. Customer will construct the foundation at their own cost.

c. The foundation should provide machine mounding point and necessary tightening joints.

d. Customer have to provide final cement work after machine installation. Canwin will provide screws for installation.

The Power Supply, Gas and Oil

a. Customer has to provide power supply to the control panels.

b. Customer has to provide air-compressor and cooler, one set each

c. Customer has to provide gear-oil, hydraulic oil, lubricating oil for the machine.

d. Customer has to provide material (coils) for commissioning work.

Production Workshop (The buyer prepared)

a. Total machine length: About 10m

b. The less floor-plan of workshop : About 25m width X 10m length X 6m height

c. Lifting equipments capable of handling minimum 10mt load and other necessary machinery for installation work.

d. Sufficient light facilities and ideal operating environment at 42 Deg C maximum.

What if precision slitting line?

The precision slitting line is used for coil with different specifications, through uncoiling--slitting--recoiling to any needed width coil.Applied to process various of metal coil, such as cold rolled steel, hot rolled steel, stainless steel, galvanize steel, aluminum, silicon steel slitting line, colored steel or painted steel.Slitting line is widely applying in metal plate processing industry, like auto car, container, household application, packing, construction material, etc.

Features of precision slitting line

With reasonable layout, full automatic, high efficiency, high productivity, high precision, high quality, steady running, easy operating.

Imported high-performance PLC control system is used to realize global control.

CPC & EPC system are optional for improve decoiling and recoiling accuracy.

With reliable and stable hydraulic system, high-strength, high-rigidity structure, and rational site configurations, the device is more convenient and practical for your operation.

FAQ

1.What can we do for you ?

We can provide you with power transformer manufacturing equipment and technical services for you to create a strong competitive transformer factory. We can provide you with special transformer OEM/ODM services. Even if you do not have the ability to produce, you can also go to pick up your order. We can provide you with all the high quality raw materials you need for your transformer plant production. Of course, the price must be very attractive!

2.How many years have your company made this kind of equipment?

We have 20 years of marketing experience and a 200,000 square foot modern manufacturing center.

3.Which certificate do you have for your equipment?

We have owned 56 patents in fields of the international invention. ISO9001 / SO14001/ STL / ASTA / KEMA

4.Can you send your staff to install the equipment for us?

After - sales free to provide engineers on-site installation and debugging and professional technical training.Answer your technical or technical questions by phone or in writing.

5.Do you have any agent in our country?

CANWIN transform and upgrade traditional industries as an opportunity to deepen the " one belt and one road" strategic layout, deepen cooperation with foreign markets. in the form of cooperation and mutual benefit, set up the transformer manufacturing center and core processing base in the Middle East, India. Dubai. Vietnam. Thailand. etc.In the future, CANWIN will move towards the direction of intelligent equipment leader, making China a global reputation!

CONTACT US

LEAVE A MESSAGE

Please fill out and submit the form below, we will contact you in 48 hours, thank you!

RECOMMENDED

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.