Izinto eziphambili zomzimba we-transformer ziquka izixhobo zesekethe yamagnetic, izixhobo zesekethe, izinto zokugquma, izinto zokwakha, njl.

Izinto eziphambili zomzimba we-transformer ziquka izixhobo zesekethe yemagnethi, izixhobo zesekethe, izinto zokugquma, izinto zokwakha, njl njl. Ukusetyenziswa kwezinto ezithile kunye neendidi zezi:

1. Iphepha lensimbi ye-silicon

Kwi-transformer, iimfuno zokusebenza kwensimbi ye-silicon ikakhulu:

①Ilahleko yentsimbi ephantsi, eyona nto ibalulekileyo yomgangatho we-silicon sheet sheet. Onke amazwe ahlula amabakala ngokwexabiso lelahleko yentsimbi. Okukhona ilahleko yentsimbi isezantsi, kokukhona inqanaba liphezulu.

②Ubungakanani bemagnetic induction intensity (imagnetic induction) iphezulu phantsi komhlaba owomeleleyo wamagnetic, onciphisa umthamo kunye nobunzima bombindi wentsimbi wemotor kunye netransformer, kwaye igcina amashiti ensimbi yesilicon, iingcingo zobhedu kunye nezixhobo zokugquma.

③Umphezulu ugudile, usicaba kwaye ufana nobukhulu, obunokuphucula into yokuzaliswa kombindi wentsimbi.

④Inokubetha kakuhle kwaye kulula ukuyiqhuba.

⑤I-adhesion kunye ne-weldability yefilimu ye-insulating surface ilungile, enokuthintela ukubola kunye nokuphucula ipropati yokubhoboza.

⑥ Ngokusisiseko akukho ukuguga magnetic.

Ukwahlula kunye nenkcazo yebakala le-silicon sheet sheet

Iziguquli zihlala zisebenzisa amacwecwe ensimbi ye-silicon eqengqelekayo eqengqelekayo ukuze kuqinisekiswe ukuba akukho mthwalo wamandla awongayo. Icwecwe le-silicon yentsimbi eqengqelekayo eqengqeleke eziziinkozo inokohlulwa ibe ishiyiti yentsimbi ye-silicon eqengqelekayo eqengqelekayo, icwecwe lensimbi ye-magnetic enokungena (okanye ishidi lentsimbi ye-silicon yokungeniswa kumagnethi), kunye neshiti lensimbi lokufaka amanqaku ngokweempawu. kunye neendlela zokucubungula. Ngokwesiqhelo, phantsi kokutshintshana kwemagnethi (ixabiso lencopho) ye-50Hz kunye ne-800A, i-silicon sheet yentsimbi enobuncinane bemagnethi polarization B800A=1.78T~1.85T ephunyezwe ngondoqo wentsimbi ibizwa ngokuba yi-silicon eqhelekileyo yentsimbi, ebizwa ngokuba yi "CGO", kunye ne-B800A = 1.85T okanye ngaphezulu Umahluko omkhulu phakathi kwentsimbi ye-Hi-B kunye nentsimbi ye-silicon eqhelekileyo yile: i-Gaussian orientation texture ye-Hi-B steel Iqondo lentsimbi ye-silicon liphezulu kakhulu, oko kukuthi, ukulungelelaniswa kweenkozo ze-silicon kwi Ulwalathiso olulula lwemagneti luphezulu kakhulu. Kwishishini, inkqubo ye-recrystallization yesibini isetyenziselwa ukwenza amaphepha ensimbi e-silicon kunye nomxholo we-silicon we-3%. Ubume bentsimbi ye-Hi-B buphezulu kakhulu. Umyinge wokutenxa ukusuka kwicala lokuqengqeleka yi-3 °, ngelixa i-silicon yentsimbi eqhelekileyo yi-7 °, ukwenzela ukuba i-Hi-B intsimbi inokufikelela kwimagnethi ephezulu, ngokuqhelekileyo i-B800A yayo inokufikelela ngaphezu kwe-1.88T, ephucula ukuthungwa kwe-Gaussian orientation kunye Ukungena kweMagnetic kunciphisa ilahleko yentsimbi. Olunye uphawu lwentsimbi ye-Hi-B kukuba i-elastic tension yefilimu yeglasi kunye ne-insulating coating encanyathiselwe kumphezulu we sheet sheet yi-3 ~ 5N / mm2, engcono kune-1 ~ 2 N / mm2 yentsimbi ye-silicon eqhelekileyo. iphepha. Umaleko woxinzelelo oluphezulu unciphisa ububanzi besizinda samagnetic kwaye unciphisa ilahleko engaqhelekanga yangoku ye-eddy. Ke ngoko, intsimbi ye-Hi-B inexabiso eliphantsi lelahleko yentsimbi kuneshiti lentsimbi yentsimbi ye-silicon yesiqhelo.

I-laser-marked silicon sheet sheet isekwe kwintsimbi ye-Hi-B, ngetekhnoloji ye-laser beam irradiation, umphezulu ucinezelekile kancinci, i-axis yamagnetic iphuculwa ngakumbi, kwaye ilahleko yentsimbi esezantsi ifunyenwe. I-Laser-marked silicon sheet sheets ayikwazi ukukhutshwa, kuba umphumo wonyango we-laser uya kunyamalala ukuba ubushushu bunyukile.

Ngokuqhelekileyo kujikeleze i-1.56T, emalunga ne-20% eyahlukileyo kwi-saturation flux density ye-silicone yensimbi eqhelekileyo ye-1.9T, ngoko ke ukuxinana kwe-design flux ye-transformer kufuneka kuncitshiswe ngama-20%. Ubuninzi be-flux yoyilo lwe-amorphous alloy oil transformers idla ngokuba ngaphantsi kwe-1.35T. Uyilo lwemagnethi yoxinaniso lwecrystalline alloy utshintsho olomileyo lukholisa ukuba ngaphantsi kwe-1.2T.

I-2) I-amorphous aggregate core strips inovakalelo kuxinzelelo. Emva kokuba imichilo engundoqo igxininiswe, ukusebenza ngokungekho mthwalo kulula ukuwohloka. Ngoko ke, ingqalelo ekhethekileyo kufuneka ihlawulwe kwisakhiwo. Ingundoqo kufuneka imiswe kwisakhelo sokuxhasa kunye nekhoyili. Ukuthwala ubunzima bayo, kwaye ngelo xesha, ingqalelo ekhethekileyo kufuneka ihlawulwe ngexesha lenkqubo yendibano, intsimbi yentsimbi ayinakugxininiswa, kwaye ukubetha kunye nezinye iindlela kufuneka zincitshiswe.

I-3) I-Magnetostriction imalunga ne-10% enkulu kunaleyo ye-silicone sheet sheets yentsimbi yesiqhelo, ngoko ke ingxolo yayo inzima ukuyilawula, nayo enye yezizathu eziphambili zokunciphisa ukukhuthazwa okubanzi kwee-amorphous alloy transformers. Ingxolo ye-transformer ibeka phambili iimfuno eziphezulu, ezahlulahlulwe kwiindawo ezinobuthathaka kunye neendawo ezingabonakaliyo, kwaye iimfuno zenqanaba lesandi zibekwe phambili ngendlela ejoliswe kuyo, efuna ukuncitshiswa ngakumbi koxinzelelo lwamagnetic loyilo oluphambili.

I-4) Uluhlu lwe-amorphous alloy luncinci, lunobunzima be-0.03mm kuphela, ngoko ke alunakwenziwa kwifom ye-lamination njenge-silicone yensimbi eqhelekileyo, kodwa inokwenziwa kuphela kwintsimbi yentsimbi edibeneyo. Ngoko ke, isakhiwo esisisiseko sentsimbi sabavelisi abaqhelekileyo be-transformer asikwazi ukuqhutyelwa ngokwabo. Ukukhupha ngaphandle, okuhambelana necandelo le-rectangular ye-coiled iron core strip, i-coil ye-amorphous alloy transformer ngokuqhelekileyo yenziwe ibe yi-rectangular structure;

I-5) Iqondo lendawo yokuhlala alanele. Okwangoku, ithathwa kakhulu kumazwe angaphandle kwimicu ye-amorphous alloy evela kwi-Hitachi Metals, kwaye ukwenziwa kwasekhaya ngokuthe ngcembe kuyenzeka. E-China, i-Antai Technology kunye ne-Qingdao Yunlu ine-amorphous alloy broadband (213mm, 170mm kunye ne-142mm). , kwaye kusekho i-gap ethile phakathi kokusebenza kwayo kunye nokuzinza kwemichilo evela kumazwe angaphandle.

I-6) Ubude obuphezulu be-strip bukhawulelwe. Obona bude buphezulu bomcu weperipheral womcu we-amorphous alloy strip kwinqanaba lokuqala nawo ulinganiselwe kakhulu ngenxa yokuthintelwa kobukhulu beziko lomlilo. Nangona kunjalo, sele isombululwe ngoku, kwaye i-alloys ye-amorphous enobude obuphezulu be-peripheral strip ye-10m inokuveliswa. Isakhelo esingundoqo sentsimbi singasetyenziselwa ukuvelisa i-3150kVA kwaye ngaphantsi kwe-amorphous alloy dry change kunye ne-10000kVA kunye nokutshintsha kweoli ye-amorphous alloy.

Ngokusekwe kwisiphumo esihle kakhulu sokugcina amandla se-amorphous alloy transformers, edityaniswa nokukhuthazwa kogcino lwamandla esizwe kunye nokunciphisa ukukhutshwa kunye nothotho lwemigaqo-nkqubo, isabelo semarike ye-amorphous alloy transformers siyanda, kwaye siqwalasela umcu we-amorphous alloy strip (okwangoku yi-26.5 yuan) ) /kg) Ixabiso limalunga nokuphindwe kabini kwiishiti zensimbi ze-silicon eziqhelekileyo (30Q120 okanye 30Q130), kwaye i-gap enobhedu incinci. Ukuqwalasela umgangatho weemveliso zegridi zamandla kunye neemfuno zebhidi, abaguquli be-amorphous alloy ngokuqhelekileyo basebenzisa abaqhubi bobhedu. Xa kuthelekiswa namaphepha entsimbi ye-silicon eqhelekileyo, izithuba eziphambili zeendleko ze-amorphous alloy transformers zilandelayo:

1) Ngenxa yesakhiwo esisisiseko senxeba, isigaba sesithathu sekholamu yesihlanu kufuneka samkelwe kuhlobo oluphambili lwe-transformer, olunokunciphisa ubunzima besiseko esisodwa kunye nokunciphisa ubunzima bokuhlanganisana. Isigaba sesithathu soluhlu lwekholamu yesihlanu kunye nesigaba sesithathu sekholamu ezintathu zineenzuzo zabo kunye nokungalunganga ngokweendleko. , Okwangoku, abaninzi abavelisi basebenzisa isakhiwo sekholamu ezintlanu zesigaba sesithathu. Isiseko sentsimbi esithengiweyo esinye kunye nendibano iboniswe kuMfanekiso 2:

2) Ekubeni icandelo lomnqamlezo we-stem lixande, ukwenzela ukugcina umgama we-insulation uhambelana, iikhoyili eziphezulu kunye ne-low voltage coil nazo zenziwe kwisakhiwo esihambelanayo soxande.

1) Ekubeni i-core design density magnetic i malunga ne-25% engaphantsi kuneyesiqhelo ye-silicon transformer sheet sheet, kwaye i-coefficient ye-lamination yombindi wayo imalunga ne-0.87, engaphantsi kakhulu kune-silicone yentsimbi ye-0.97 yesiguquli seshidi yentsimbi, uyilo lwayo indawo yecandelo kufuneka ibe nkulu kuneyo yesiqhelo i-silicon steel sheet transformers. Ukuba inkulu kune-25%, i-perimeter ehambelanayo yeekhoyili eziphezulu kunye ne-low voltage coil nazo ziya kwanda ngokufanelekileyo. Ngexesha elifanayo, kuyafuneka ukuba kuqwalaselwe ukunyuka kobude be-coil coil ephezulu kunye nephantsi. Ukuqinisekisa ukuba ukulahlekelwa komthwalo we-coil akutshintshi, indawo enqamlekileyo yocingo kufuneka ihambelane Ngokuhambelanayo, umxholo wobhedu we-amorphous alloy transformers malunga ne-20% ephezulu kuneyenguqu eqhelekileyo.

3. Izinto zeSekethe

Isishwankathelo

Isiphaluka sangaphakathi se-transformer ikakhulu siqulunqwe ngama-windings (eyaziwa nangokuthi iikhoyili). Idibaniswe ngokuthe ngqo kwigridi yamandla yangaphandle kwaye iyona nxalenye ephambili ye-transformer. Isiphaluka sangaphakathi se-transformer ngokuqhelekileyo senziwe nge-wire windings. Iingcingo zobhedu kunye neengcingo ze-aluminiyam zahlulwe zibe ziingcingo ezijikelezayo, iingcingo ezisicaba (ezinokuthi ziphinde zohlulwe zibe yingcingo enye, iingcingo ezidibeneyo kunye neengcingo eziguqulwayo), ii-conductor ze-foil, njl. iileya, kwaye ekugqibeleni wenze ikhoyili iyonke. Ngoko ke, izinto eziphambili ze-conductor zesekethe ye-transformer zibhedu kunye ne-aluminium.

3.1 Ukuthelekiswa kweempawu zobhedu kunye ne-aluminium

Zombini ubhedu kunye ne-aluminium zizinto zetsimbi ezine-conductivity efanelekileyo yombane kwaye zisetyenziswa ngokuqhelekileyo ii-conductors ukwenza iikhoyili ze-transformer. Umahluko kwiipropathi ezibonakalayo ubonisiwe kolu luhlu lulandelayo:

3.2 Ukuthelekisa ukusebenza kweengcingo zobhedu-aluminiyam kwii-windings ze-transformer

Umahluko we-copper-aluminium transformer nayo inqunywe ngumahluko wezinto eziphathekayo, eziqulethwe kule miba ilandelayo:

I-1) I-resistiveivity yabaqhubi bezobhedu kuphela malunga ne-60% yabaqhubi be-aluminium. Ukuze kuphunyezwe ilahleko efanayo kunye neemfuno zokunyuka kweqondo lokushisa, indawo enqamlezileyo yabaqhubi be-aluminium ekufuneka isetyenziswe ingaphezulu kwe-60% enkulu kuneyeziqhubi zobhedu, ngoko ke umthamo ofanayo kunye neeparitha ezifanayo ziyafuneka. Umthamo we-aluminium umqhubi we-transformer udla ngokuba mkhulu kunalowo we-copper conductor transformer, kodwa indawo yokutshatyalaliswa kobushushu be-transformer nayo yanda ngeli xesha, ngoko ukunyuka kweqondo lokushisa kweoli kuphantsi;

2) Ubuninzi be-aluminium bumalunga ne-30% kuphela yobhedu, ngoko ke i-aluminium conductor distribution distribution transformers ilula kune-copper conductor distribution transformers;

3) Indawo yokunyibilika yomqhubi we-aluminium iphantsi kakhulu kunomqhubi wobhedu, ngoko ke umlinganiselo wokunyuka kweqondo lokushisa kwi-short-circuit current yi-250 ℃, engaphantsi kwe-350 ℃ yomqhubi wobhedu. Enkulu, ngoko ke umthamo ubuye mkhulu kune-copper conductor transformer;

4) Ubunzima bomqhubi we-aluminium buphantsi, ngoko ke i-surface burr ilula ukuphelisa, ngoko emva kokuba i-transformer yenziwe, amathuba okuba i-inter-turn okanye i-inter-layer short circuit ebangelwa yi-burr iyancitshiswa;

I-5) Ngenxa ye-tensile ephantsi kunye ne-compressive yamandla abaqhubi be-aluminium kunye namandla aphantsi omatshini, i-aluminium conductor transformers ayinakho ukukwazi ukujikeleza okufutshane njenge-copper conductor transformers. Umda woxinzelelo lwe-conductor yi-1600kg / cm2, kwaye umthamo wokuthwala uphuculwe kakhulu;

6) Inkqubo ye-welding phakathi komqhubi we-aluminium kunye nomqhubi wobhedu ihlwempu, kwaye umgangatho we-welding we-joint akulula ukuqinisekiswa, ochaphazela ukuthembeka komqhubi we-aluminium ukuya kwinqanaba elithile.

7) Ubushushu obuthile bomqhubi we-aluminium yi-239% yomqhubi wobhedu, kodwa xa kuqwalaselwa umahluko kuxinaniso kunye noyilo loxinaniso lombane phakathi kwezi zibini, elona xesha le-thermal umahluko phakathi kwezi zibini alikho likhulu njengobushushu obuthile. umahluko. Umthamo ogqithisiweyo wexesha elifutshane wenguqu eyomileyo inefuthe elincinci.

4. Izinto zokugquma

Isishwankathelo

Ukuthembeka kunye nobomi benkonzo ye-transformer, nangona kunjalo, kuxhomekeke kumlinganiselo omkhulu kwizinto ezisetyenziswayo zokugquma. Izixhobo zokugquma, ezikwabizwa ngokuba yi-dielectrics, zizinto ezinokumelana okuphezulu kunye ne-conductivity ephantsi. Izinto zokugquma zingasetyenziselwa ukwahlula ii-conductor ezihlawuliswayo okanye ngokwamandla ahlukeneyo, zivumela i-current ukuba ihambe kwicala elithile. Kwiimveliso ze-transformer, izinto zokukhusela zidlala indima yokutshatyalaliswa kobushushu, ukupholisa, ukuxhaswa, ukulungiswa, ukucima i-arc, ukuphuculwa kwe-gradient enokwenzeka, ukuxhathisa ukufuma, ukuxhathisa ukubola kunye nokukhusela i-conductor. Ngaphantsi kwesenzo se-voltage ye-DC, kuphela i-current encinci kakhulu ehamba nge-insulating material. Ukumelana kwayo (kubhekiselele kwi-resistivity yevolumu emoyeni) iphezulu, ngokubanzi 108 ~ 1020Ω·cm (i-resistantivity ye-conductor yi-10-6 ~ 10-3Ω·cm, kunye nokumelana kwe-semiconductor yi-10-3~ 108Ω cm).

Izinto zokugquma zinokumelana okukhulu kakhulu ne-DC yangoku. Ngenxa yokuxhathisa kwayo okuphezulu, phantsi kwentshukumo yombane we-DC, ayinaku-conductive ngaphandle kwendawo evuzayo encinci kakhulu yangoku; ngelixa inamandla kwi-AC yangoku. Umsinga wombane ukwabonwa ngokubanzi njengento engasebenziyo. Ukuphakama kwe-resistiveivity ye-insulating material, bhetele iimpawu zayo zokukhusela.

Izinto zokugquma zisetyenziselwa ii-transformers ukuba zihlukanise iindawo zokuqhuba ukusuka komnye nomnye ukuya emhlabeni (zero potential). Xa zisetyenziswa kwiinkxaso ezahlukeneyo, kufuneka kwakhona zibe neempawu ezilungileyo zoomatshini. Ukongezelela, izinto zokukhusela zidlala nezinye iindima, ezifana nokupholisa, ukulungiswa, ukugcinwa kwamandla, ukucima i-arc, ukuphucula i-gradient enokwenzeka, ubungqina bomswakama, ubungqina be-mildew kunye nokukhusela abaqhubi.

Ngokuqhelekileyo, izixhobo zokukhusela ziwela kwiindidi ezintathu:

I-1) Izixhobo zokukhusela igesi: Ngaphantsi kobushushu obuqhelekileyo kunye noxinzelelo, iigesi ezomileyo eziqhelekileyo zineendawo ezintle zokukhusela, ezifana nomoya, i-nitrogen, i-hydrogen, i-carbon dioxide, i-sulfur hexafluoride, njl. ngokubanzi;

2) Izinto zokugquma ulwelo: Izinto zokugquma ulwelo zihlala zikhona ngendlela yeoli, ekwabizwa ngokuba yioyile yokugquma. Okufana namafutha amaminerali, i-oyile yemifuno, i-synthetic esters, njl.;

3) Izinto zokugquma eziqinileyo: ezifana nepeyinti yokugquma, iglue, iphepha lokugquma, ikhadibhodi, ibhodibhodi, iiplastiki zombane kunye neefilimu, i-laminates zombane (iintonga, iityhubhu), i-epoxy resin, i-porcelain yombane, irabha, iimveliso zemica, njl.

4.1 Ioli yokugquma

Ioli yokukhusela ibonakaliswe ngamandla ombane aphezulu, umbane ophezulu, indawo ephantsi yokukhenkcela, ubushushu bokusebenza phantsi kwesenzo se-oksijeni, ubushushu obuphezulu kunye nentsimi yombane enamandla, i-non-toxic, non-corrosive, viscosity ephantsi, i-fluidity enhle kunye nokunye. Isetyenziswa ngokubanzi kwiimveliso zombane ezifana ne-transformers, i-oyile yokutshintsha, i-capacitors kunye neentambo, kwaye idlala indima yokugquma, ukupholisa, ukufakwa kunye nokuzaliswa. Ukongeza, iphinda idlale indima yokucima i-arc ekutshintsheni kweoli kunye nokugcinwa kwamandla kwii-capacitors.

I-oyile yokukhusela idlala indima emibini ye-insulation kunye nokupholisa kwi-transformer ngexesha elifanayo;

Ioyile ezikhuselayo ngokwangoku zohlulwe ngokwezi ndidi zilandelayo:

1) Ioli yamaminerali: njengeoli ye-transformer, ioli yokutshintsha, ioli ye-capacitor, ioli yentambo;

2) Ioli yokwenziwa: njenge-dodecylbenzene, ioli ye-silicone, i-synthetic ester, njl.;

3) Ioli yemifuno;

4.2 I-epoxy resin

I-epoxy resin yi-polymer compound. I-resin ibonakaliswe yinto eqinileyo, i-semi-solid okanye i-quasi-solid organic material kunye ne-molecular mass (ngokuqhelekileyo iphezulu), ukuthambekela kokuhamba xa iphantsi koxinzelelo, ngokuqhelekileyo uluhlu oluthambileyo okanye olunyibilikayo, kunye necandelo elinqamlekileyo elihlala lihlala. ibonisa imilo efana neqokobhe. Inezi mpawu zilandelayo:

1) Itsheyini yemolekyuli inde kakhulu, ikhonkco ngalinye liqulethe amakhulu okanye amashumi amawaka eathom, ezibotshelelwe ngokudibeneyo omnye komnye;

2) Ikhonkco elide le-molecular liqulunqwe yiyunithi encinci yokuphinda, oko kukuthi, ikhonkco lekhonkco, kunye nenani lekhonkco lekhonkco kwi-molecule libizwa ngokuba yi-degree of polymerization;

I-3) I-total intermolecular force ye-macromolecules ihlala idlula amandla okubambisana kweekhemikhali phakathi kwe-athomu kwi-athomu, ukwenzela ukuba i-polymer compounds ibe nochungechunge lweempawu: umzekelo, akukho polymer yegesi, inkqubo yokuchithwa kwe-polymer icotha kakhulu, njl. kukho ukudibanisa phakathi kweemolekyuli, Olu phawu lohluke ngakumbi.

I-epoxy resin ibhekisela kwiioligomers eziqukethe amaqela asebenzayo epoxy. I-epoxy resins yaqala ukubonakala ngo-1891. Emva kwe-1947, iinkampani ezininzi e-United States nase-Switzerland zenza ngempumelelo i-bisphenol A epoxy resins kwimizi-mveliso. ilizwe lam laqala imveliso ngo-1956.

Iimpawu zokugquma umbane zezinto ze-epoxy zibalaseleyo. Xa i-filler ingafakwanga, i-EB yemveliso ephilisiweyo iphezulu kune-16MV/m, i-pV iphezulu kune-1011Ω·m, i-εr yi-3 ukuya ku-4, kwaye i-tanδ imalunga ne-0.002 phantsi kwe-frequency yamandla. Ngoko ke, i-20% ye-ring ye-Oxygen resins isetyenziselwa ukugquma kombane kunye ne-electronic, njengepeyinti yokufaka i-epoxy njengepeyinti ye-B-class insulating, ukufaka i-motor stator windings encinci kunye nephakathi; Ipeyinti ye-epoxy-solvent-free isetyenziselwa ukufakwa kwe-vacuum ye-motor stator windings enkulu; i-laminates (iipleyiti, iityhubhu, ii-Rods) zisetyenziswa njenge-slot wedges kunye ne-spacers of motors, i-high-voltage switch switching stickers; i-adhesives isetyenziselwa ukudibanisa i-high-voltage electric porcelain bushings; ii-castables zisetyenziselwa i-disc isolation kwi-sulphur hexafluoride efakwe ngokupheleleyo kwizixhobo zombane ezidibeneyo (GIS). Amacandelo afana ne-insulators, i-transformers kunye ne-high-voltage ceramic capacitors. Okwangoku, amagama e-brand epoxy resins okanye i-epoxy resins ehlaziyiweyo eveliswe e-China ayifani ngokufanayo okwangoku. Amagama abavelisi abahlukeneyo be-epoxy resin kwihlabathi jikelele ahlukile kwaye kufuneka achongwe ngophawu lwentengiso.

I-Epoxy resins zi-oligomers kwaye zinokusetyenziswa kuphela emva kokunyanga. I-agent ephilisayo inokusabela kunye ne-epoxy resin ukuwela i-molecule ye-resin ukusuka kwisakhiwo somgca kwisakhiwo esikhulu. Abagqugquzeli / ii-catalysts banokunciphisa amandla okusebenza kokuphendula kwaye banokukhuthaza / ukulungelelanisa inkqubo ye-gel reaction ye-castable. I-arhente yokunyanga isebenzisa i-hydrogen esebenzayo equlethwe kuyo ukwenza i-ring-opening reaction reaction kunye neqela elisebenzayo le-epoxy kwi-resin ukuphumeza ukunyanga. I-hydrogen esebenzayo yi-NH2, -NH-, -COOH, -OH kunye -SH kwi-arhente yokunyanga okanye i-accelerator. kwihydrogen. Iiarhente zokunyanga ezisetyenziswa ngokuqhelekileyo zii-amines kunye ne-acid anhydrides. Ezinye ii-agent zokunyanga zifuna i-accelerators / catalysts, ezinye zifuna iimeko eziphezulu zokushisa, kwaye ezinye zinokusabela ngobundlobongela kumaqondo aphantsi. Ii-agent ezahlukeneyo zokunyanga nazo ziya kukhokelela kumahluko omkhulu kwiipropati zeemveliso eziphilisiweyo, ezinempembelelo ebalulekileyo kwiipropati zokugqibela zemveliso. Ke ngoko, kubaluleke kakhulu ukuyila kunye nokukhetha iarhente yokunyanga kwinkqubo yokwenziwa kwe-epoxy resin.

I-epoxy insulation isetyenziswe kwiinguqu zodidi ezomileyo kwaye luphuhliso olutsha kwiminyaka engama-40 edlulileyo. Ubomi boyilo lwekhoyili ye-transformer bufunekayo ukufikelela kwiminyaka engama-30, kwaye ibakala lokumelana nokushisa kufuneka lifikelele kwi-F grade. Kunzima kwizinto eziqhelekileyo ukuhlangabezana neemfuno.

Kule njongo, kuyimfuneko ukuyila, ukwandisa, ukuvavanya kunye nokuqinisekisa izinto ezisetyenzisiweyo kunye neenkqubo zokuqulunqa kunye neenkqubo ukuze ufumane umphumo ofunekayo. Kwi-resin-insulated dry-type transformer, inkqubo ye-epoxy resin yenziwa ngokuphosa okanye ukudipha, kwaye emva koko iphiliswe nge-thermal ukwenza i-coil insulation (oko kukuthi, i-longitudinal insulation). Ngethuba lonke lomsebenzi we-transformer yohlobo olomileyo, i-epoxy resin insulation kufuneka iphinde iqinisekise ukutshatyalaliswa kombane wekhoyili kunye namandla omatshini, kwaye uchithe ukushisa ngaphakathi kwekhoyili ngokusebenzisa i-thermal conduction.

Ubuthathaka bayo obukhulu kukungaguquki kunye nokungenakulungiseka kweziphene ze-resin insulation kunye nomonakalo (ngokuqhelekileyo iziphene kwinkqubo yokuvelisa kunye nomonakalo kwinkqubo yokusebenza). Ke ngoko, ukuphepha ukuqhekeka kokugquma okuqinileyo, ukuphepha ukuphosa iziphene, kunye nokuphepha ukukhutshwa okungaphelelanga (oko kukuthi, ukukhutshwa kwenxalenye) kubaluleke kakhulu, kwaye kube sisitshixo sokwenza itekhnoloji eqinileyo yokwenziwa kwe-insulation, kwaye kugxilwe kukhuphiswano phakathi kwabavelisi.

Ngenxa yokunyuka kobushushu obuphezulu obubangelwa yilahleko ngexesha lokusebenza kwe-transformer, ukugqunywa kwe-resin kusebenza kwiqondo lokushisa eliphezulu ixesha elide (elifana ne-F-class transformer, ubushushu obuphezulu obuyilwe bokusebenza ngokubanzi bujikeleze i-140 ℃), kwaye i-transformer ingaba kwiqondo lokushisa eliphezulu ngaphambi kokugunyaziswa kunye nexesha lokugcinwa. Ubushushu obuphantsi (njenge--30 ℃), kwaye i-transformer iya kuba phantsi kokutshatyalaliswa kombane omkhulu wombane we-high-voltage shock okanye isiphaluka esifutshane nangaliphi na ixesha. Iikhoyili ezifakwe kwi-resin-insulated kufuneka zikwazi ukuziqhelanisa nolu tshintsho, kwaye zikwazi ukumelana okanye zixhathise i-short-circuit electrodynamic shock kumaqondo obushushu aphezulu kakhulu naphantsi. Ke ngoko, iimfuno ezingqongqo kakhulu zibekwe kwi-thermal, mechanical kunye nepropathi yombane ye-epoxy insulation systems.

Okwangoku kukho iindidi ezimbini zenkqubo ye-insulating ye-resin cast transformers, enye "yi-resin ecocekileyo yokugalela + izinga lokuzalisa i-fiber fiber yeglasi ephezulu", kwaye enye "yi-resin quartz powder cast + prepreg glass mesh ukuqiniswa kwendawo".

Inkqubo yokugquma (oko kukuthi, i-insulation structure) igubungela intsimi ebanzi kunenkqubo ye-insulation material. Ibhekisela kwi-insulation yezixhobo zombane (okanye iinqununu zayo ezizimeleyo) ngokubanzi, kubandakanywa kungekhona nje kuphela izinto zokugquma kunye nokudibanisa kwazo, kodwa kunye ne-insulation kunye nabaqhubi. Okanye ubudlelwane phakathi kwemagnethi, ubudlelwane kunye nebala lombane, ubudlelwane phakathi kokugquma kunye nokusingqongileyo (igesi okanye ulwelo kunye neemeko zalo, ukungcoliseka komphezulu, iimeko zokulahla ubushushu, amandla omatshini okanye ukusasazeka kwemitha, njl. njl.), kunye ukuguquguquka kwiiparamitha zokusebenza zenkqubo yamandla I-insulation. Ukuhamba komoya kunye nokutshatyalaliswa kobushushu kwi-transformer yohlobo olomileyo, uxinzelelo lwe-insulation, njl.

4.3 Iphepha le-insulation

Iphepha lefiber yezityalo lahlulwe libe yifayibha yomthi, ifayibha yomqhaphu kunye nefayibha ye-hemp, apho eyona nto isetyenziswa kakhulu liphepha lefiber ye-sulfate yomthi. I-Fir kunye ne-Korean pine kunye nezinye iinkuni zenziwe ngokukodwa nge-cellulose, i-polymer compound yendalo. Indlela yokuvelisa i-insulating paper ithatha indlela yekhemikhali, njengendlela ye-sulfate. Kule ndlela, inxalenye ephambili ye-liquid yokupheka i-sodium sulfide (Na2S). I-sodium sulfide i-hydrolyzed ukwenza i-sodium hydrogen sulfide kunye ne-sodium hydroxide. I-cellulose iyaphendula kwaye iyinyibilikise kwi-lye. I-liquid yokupheka incinci, ngoko ubunzima be-molecular of cellulose buyancipha kakhulu. Amaphepha asetyenziswa ngokuqhelekileyo eplanti ye-cellulose insulating in transformers are: power cable paper, high-voltage cable paper kunye netransformer inter-turn insulating paper.

1) Iphepha lekhebula: Iphepha lekhebula lenziwe nge-kraft pulp, amabakala yi-DL08, DL12, DL17, ubukhulu buyi-0.08mm, 0.12mm kunye ne-0.17mm, ngokulandelanayo, kwaye zibonelelwa ngemiqulu. Emva kokuba iphepha lekhebula lifakwe ngeoli ye-transformer, amandla ayo omatshini kunye Amandla ombane aya kuphuculwa kakhulu. Ngokomzekelo, amandla ombane wephepha lentambo yamandla emoyeni ngu-6 ~ 9 × 103kV / m, kwaye emva kokumisa nokucwiliswa kweoli ye-transformer, amandla ombane afikelela kwi-70 ~ 90 × 103kV / m. Inozinzo olwaneleyo lwe-thermal kwaye idla ngokusetyenziswa njenge-winging insulation kunye ne-interlayer insulation. Iphepha lekhebula likwabandakanya i-high-voltage cable paper, i-low-voltage cable paper, i-high-density cable paper kunye ne-insulating crepe paper. Iphepha le-high-voltage cable lifanelekile kwi-110-330kV i-transformers kunye ne-transformers, kunye ne-tangent yokulahleka kwe-dielectric ephantsi; iphepha le-cable low-voltage lisetyenziselwa ukugquma iintambo zamandla kunye neenguqu okanye ezinye iimveliso zombane ze-35kV nangaphantsi; i-insulating crepe paper yenziwe ngephepha lokugquma umbane. Yenziwe ngokulungiswa kwemibimbi, kwaye kukho imibimbi ecaleni kwendlela yayo enqamlezileyo, etsalwa ngaphandle xa isoluliwe. Ihlala isetyenziselwa ukugquma i-insulation ye-oyile-immersed transformers, ezifana ne-insulation wrapping of coil outlets, ii-lead kunye nezixhobo zokukhusela i-electrostatic; Iphepha lentambo elinoxinaniso oluphezulu nalo likhusela uhlobo lwephepha le-crepe, amandla ombane yi-100% ukuya kwi-150% ephezulu kunephepha le-crepe jikelele, amandla omatshini angama-50% aphezulu, amandla ombane aphezulu, ukuxhathisa kwe-oyile kulungile, i-elasticity ilungile, kwaye kulula ukuyolula. Ingasetyenziswa njengesikhokelo endaweni yetape enevanishi. kunye ne-insulation of wire connections and bends.

2) Iphepha lomnxeba: Iphepha lomnxeba lenziwe nge-sulfate pulp, esetyenziswa ngokuqhelekileyo kwiintambo zomnxeba. Inamandla omatshini asezantsi kwaye isetyenziswa ngokubanzi njengokugquma ukujika, ukugquma umaleko okanye ukugquma kwezikhonda-ndlela.

3) Iphepha le-Capacitor: Iphepha le-Capacitor lihlukaniswe kwiKlasi A kunye neKlasi B ngokweemfuno zokusetyenziswa. Iphepha le-Capacitor leKlasi A lisetyenziselwa i-metallised paper dielectric capacitors kwishishini lombane. Udidi B lusetyenziswa ikakhulu njenge-interpole dielectric yee-capacitors zamandla. Iphepha leCapacitor libonakaliswa ngokuqina okuphezulu kunye nobukhulu obuncinci. Ngokuqhelekileyo, abaguquli bangoku bahlala besebenzisa iphepha le-capacitor, kwaye i-transformers ayifane isetyenziswe.

4) Iphepha eligqunyiweyo le-insulating lisetyenziswa njengephepha elixhasayo lephepha lokulinganisa, kwaye iphepha lokulinganisa lisetyenziselwa ukuvuthela isilinda (ityhubhu) kunye nomkhono we-capacitive, obonakaliswe ngokuba ukuphakama kwamanzi kuphezulu. kunephepha lentambo kwaye lisezantsi kunePhepha lokufakela. Iphepha elidityanisiweyo lihlulwe libe licala elinye okanye i-double-sided glued (phenolic okanye i-epoxy resin), ephiliswa kwiqondo lokushisa eliphantsi. Xa iphepha elidibeneyo lisetyenziselwa ukwenza ityhubhu yephepha okanye ucinezele i-laminate, iglue ekugqibeleni iyaphiliswa xa ishushu kwaye icinezelwe. , Umqulu ngokubanzi yi tape ecala-nye, kwaye itheyiphu ecinezelweyo yi tape enamacala amabini. Ukongeza, kukwakho nephepha ledayimane elincamathelweyo (i-mesh glued paper), esetyenziselwa ukufakwa kwe-interlayer ye-oil-immersed foil winding coils. Emva kokunyanga, iqinisekisa ukunamathela phakathi kokufakwa kunye phakathi kwe-insulation kunye ne-foil, ukuqinisa Amandla kunye nokuhamba kakuhle kweoli.

Iphepha eliqhelekileyo le-transformer insulating lisetyenziswa kakhulu kwi-cable paper, i-crepe paper kunye ne-rhombus dispensing paper, ezisetyenziswa kwi-transformers njenge-inter-turn insulation, i-inter-layer insulation, i-lead binding, njl. Ngokuqhelekileyo, amaxabiso eentlobo ezahlukeneyo zephepha lokukhusela ayahlukanga. Iya kuba nkulu kakhulu, malunga ne-20 yuan/kg.

4.4 Izinto ezixutywe nombane

Iifilimu ezicekethekileyo zombane kunye nezixhobo ezidibeneyo zombane zineempawu ezintle ze-dielectric kwaye zezemathiriyeli encinci yokugquma. Iifilimu zombane ziquka ifilimu ye-polyester kunye nefilimu ye-polyimide, enokuthi isetyenziswe njenge-insulation yocingo kunye ne-interlayer insulation in transformers. Izinto ezihlanganisiweyo zombane yimveliso edibeneyo eyenziwe kwicala elinye okanye amacala amabini efilim ebontshwe ifayibha imathiriyeli, enokusetyenziswa njenge-interlayer insulation in transformers, ingakumbi kwiicoil zenxeba eziguquguqukayo ezomileyo, kunye neecoil ezine-voltage ezisezantsi zihlala zenziwe. imathiriyeli edibeneyo. Emva kokufakwa kwi-resin, isetyenziswe njenge-interlayer insulation. Iimathiriyeli ezisetyenziswa ngokuqhelekileyo zi-DMD, GHG njalo njalo.

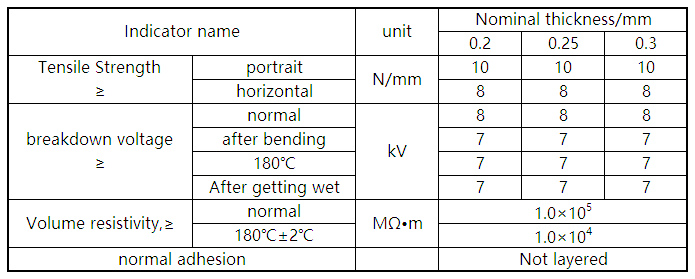

Igama elipheleleyo le-DMD yi-polyester film polyester fiber non-woven soft composite material, eyahlulahlulwe kwi-pre-impregnated resin DMD kunye ne-DMD engafakwanga ngaphambili. D) Umdibaniso othambileyo womaleko-ntathu owenziweyo. I-DMD inombane ogqwesileyo wokugquma, ukumelana nobushushu kunye nokomelela koomatshini kunye neempawu ezigqwesileyo zokufakela. I-DMD engekho-prepreg ingasetyenziswa njenge-interlayer insulation ye-oyile-immersed transformers, kunye ne-prepreg DMD ingasetyenziswa njenge-interlayer insulation ye-low-voltage foil inxeba iikhoyili kwi-Class F dry-type transformers. Izalathi zayo zokusebenza ezithile zibonisiwe kolu luhlu lulandelayo:

Igama elipheleleyo le-GHG yifilimu ye-polyimide efakwe ngaphambili i-H-grade resin yeglasi yefiber ethambileyo imathiriyeli. Yimathiriyeli enemigangatho emithathu ethambileyo eyenziwe ngelaphu leglasi yefiber (G) encanyathiselwe macala omabini efilimu yepolyimide (H). . Xa kuthelekiswa ne-DMD, inokumelana nobushushu obungcono kwaye ingasetyenziselwa ukugquma kwe-interlayer ye-foil ephantsi-voltage iikhoyili zenxeba le-H-class insulation dry-type transformers.

Igama elipheleleyo le-NHN yi polyimide film polyaramid fiber paper soft composite material. I-NHN okwangoku yeyona nto ikumgangatho ophezulu wezinto ezikhuselayo ezinomgangatho ophantsi, ezinokuxhathisa ubushushu, iipropathi ezilungileyo zedielectric, ukufunxwa kwamanzi amancinci kunye nokuxhathisa okugqwesileyo kokufuma. Yeyomgangatho we-insulating weklasi H kwaye ingasetyenziselwa ukugquma kwe-interlayer yeklasi H ezomileyo zohlobo lwe-transformers. Iiparamitha zayo ezithile zokusebenza zibonisiwe kolu luhlu lulandelayo:

4.5 Ikhadibhodi yokugquma

I-insulating paperboard yenziwe nge-kraft wood pulp papermaking ecocekileyo kwaye ingasetyenziselwa i-oyile gap spacers, i-oil gap ihlala, izahluli, iityhubhu zekhadibhodi, iphepha elityaliweyo, ukugqunywa kwedyokhwe yentsimbi, ukugqunywa kwekliphu kunye nokuphelisa iipleyiti zoxinzelelo ezijikajikayo zokujija iipayi njl.njl., ubukhulu obuqhelekileyo yi-1.0mm, 1.5mm, 2mm, 3mm, 4mm, 6mm, ikhadibhodi ekhuselayo yohlulwe ibe yikhadibhodi yoxinaniso oluphantsi, i-medium-density cardboard kunye ne-high-density cardboard ngokobuninzi, iphepha eliphantsi-lihlala libizwa ngokuba yi-T3 ethambileyo yekhadibhodi. , Ubuninzi buphakathi kwe-0.75g / cm3 kunye ne-0.9g / cm3, amandla aphantsi, kwaye ahlala esetyenziselwa ukugoba iindawo okanye ukwenza iindawo ezolulayo emva kokumanzisa, ezifana nokwenza amakhonkco e-angle, amacandelo e-annular kunye neetyhubhu zephepha ezithambileyo. Ikhadibhodi yoxinaniso olusezantsi inezinga eliphezulu lokufunxa ioyile, ukumila kakuhle, kodwa iipropathi ezingalunganga zoomatshini; i-medium-density cardboard idla ngokubizwa ngokuba yi-T1 cardboard, kunye noxinaniso phakathi kwe-0.95g / cm3 kunye ne-1.15g / cm3, esetyenziswa njengendawo yokuhlala, njl.; Ikhadibhodi yoxinaniso oluphezulu Ikhadibhodi idla ngokubizwa ngokuba yi-T4 yekhadibhodi, enoxinano lwe-1.15g/cm3 ukuya kwi-1.3g/cm3, kwaye isetyenziswa njengetyhubhu yekhadibhodi ekhuselayo, ipleyiti yoxinzelelo lokukhusela kunye neringi yokuphela. Kwi-oil-board spacer structure eyenziwe nge-high-voltage coil multi-layer paper tubes, i-cardboard corrugated nayo ingasetyenziselwa endaweni ye-cardboard struts ukwenza i-oil gaps, enokugcina izinto eziphathekayo ngesiseko sokuqinisekisa ukusebenza kwe-insulation.

4.6 ifilimu yePolypropylene

Ifilimu ye-polypropylene yenziwe nge-polypropylene resin (PP) ikhutshwe kwiphepha elishinyeneyo kwaye yolulwe kwicala. 0.92g/cm3. I-2) Inezinto ezintle zombane kunye nokuzinza kweekhemikhali, i-coefficient ye-dielectric ehambelanayo yi-2 ukuya ku-2.2, kwaye uxinzelelo lokuphuka lungaphezu kwe-150MV / m; 3) Ineempawu ezilungileyo zoomatshini, kwaye amandla ayo okuqina angaphezulu kwe-100MPa; 4) Ingasetyenziselwa ixesha elide kwi-125 ℃ kwaye iyingxenye ye-E-class insulation; 5) Ine-hydrophobicity kunye nobuchule obunamandla bokuchasana namanzi, kwaye ingasetyenziselwa ukugquma ucingo lwe-oil-immersed transformers.

4.7 Ezinye izixhobo zokugquma

Ioli ye-transformer kunye ne-insulating paper yizona zinto zibalulekileyo zokukhusela i-oil-immersed transformer coil. I-resin, i-insulating paper, kunye nezixhobo ezidibeneyo zezona zinto zibalulekileyo zokukhusela iikhoyili zohlobo olomileyo. Ukongeza kwezi zixhobo, ezi zinto zilandelayo zokukhusela zisetyenziswa ngokuqhelekileyo kwi-transformers: (umthi odibeneyo, i-laminate, i-insulating paint, i-insulating glue, i-cotton tape, i-compression tape, akukho tape ye-weft, njl.

I-1) I-Laminate: I-laminate yombane yinto yokukhusela eyenziwe ngephepha, ilaphu kunye ne-veneer yeplanga njenge-substrate, iditywe (okanye ifakwe) kunye ne-adhesives eyahlukeneyo, kunye ne-hot pressed (okanye i-rolled). . Ngokweemfuno zokusetyenziswa, iimveliso ze-laminated zingenziwa kwiimveliso ezinombane obalaseleyo kunye noomatshini, ukumelana nobushushu, ukuxhathisa kweoli, ukunyanzeliswa kwe-mildew, ukumelana ne-arc kunye nokumelana ne-corona. Iimveliso ze-laminate ikakhulu ziquka i-laminates, i-laminated wood, i-tubes laminated, iintonga, i-capacitor sleeve cores kunye nezinye iiprofayili ezikhethekileyo. Iimpawu ze-laminates zixhomekeke kubume be-substrate kunye ne-adhesive kunye nenkqubo eyenziwa ngayo. Ngokutsho kwezixhobo ezahlukeneyo kunye ne-adhesives, i-laminates yahlulwe ibe yi-laminates ezikhuselayo (i-paperboard, esetyenziselwa ukutshintsha ioli), i-phenolic laminated paperboard (eyaziwa ngokuba yi-bakelite, i-paperboard efakwe kwi-phenolic resin, esetyenziselwa ukutshintsha ioli), i-phenolic laminated board board (umqhaphu ilaphu elifakwe i-phenolic resin, elisetyenziswa ngokuqhelekileyo ukutshintsha ioli), ibhodi yelaphu yeglasi ye-epoxy (ilaphu leglasi yefiber ene-epoxy resin njenge-adhesive, ingasetyenziselwa i-F grade utshintsho olomileyo okanye utshintsho lwe-oyile), ibhodi yelaphu ye-diphenyl ether yeglasi elungisiweyo (ilaphu le-Glass fiber isebenzisa i-resin ye-diphenyl ether eguquliwe njenge-adhesive, engasetyenziselwa i-H-level dry change), ibhodi yelaphu yeglasi ye-bismaleimide (i-glass fiber cloth isebenzisa i-bismaleimide resin njenge-adhesive, Ingasetyenziselwa i-H-level dry change). I-Laminates idla ngokuba namandla omatshini kunye neempawu zokugquma, kwaye zihlala zisetyenziswa njenge-core clip insulation, izixhaso zangaphandle, njl. kwiziguquli.

I-2) I-cylinder ye-insulation (i-tube): I-cylinder yokukhusela kwi-transformer isetyenziswa kakhulu phakathi kwee-coil zangaphakathi nangaphandle, phakathi kwekhoyili kunye nentsimbi yentsimbi, kwi-coil ebeka i-skeleton, kwaye ucingo lulimala ngokuthe ngqo kwi-cylinder yokukhusela. Ngexesha elifanayo, i-cylinder yokukhusela ingasetyenziselwa i-Insulation eyintloko, yandise inani lezithuba zeoli kwi-insulation engundoqo, kwaye uqinise ukugquma. Ngokwezixhobo ezahlukeneyo, ityhubhu yokugquma yahlulahlulwe ngokubanzi ibe ityhubhu yephepha lephenolic (ehlala isetyenziselwa ukutshintshwa kweoyile), ityhubhu yelaphu yeglasi epoxy (ehlala isetyenziselwa ukutshintsha kweoyile okanye inqanaba leF lokutshintsha okomileyo), idiphenyl ether ityhubhu yelaphu yeglasi elungisiweyo (ehlala isetyenziswa. ukutshintshwa kweoli) i-H-level dry change), i-glass fiber iqiniswe kwi-cylinder yeplastiki (ehlala isetyenziswa kwi-H-level dry change), i-bismaleimide glass cylinder cylinder (ehlala isetyenziswa kwi-H-level dry change), njl.

3) Iplanga elaminethiweyo: Umthi owenziwe ngombane wenziwa ngamaplanga aqinileyo akumgangatho ophezulu, njengebirch, beech, njl. kwaye emva koko usike kwiinqununu ezizimeleyo ze-1 ukuya kwi-3 mm. Emva kokumisa, ifakwe nge-resin adhesive. Emva kokunyanga kwangaphambili, ihlanganiswe ngokuphindaphindiweyo kwaye ifakwe. Inamandla okukhusela kakuhle kunye namandla omatshini. Ingasetyenziswa njenge-spacer, i-angle ring, njl. kwinguqu yeoli. .

1) Iiteyiphu ezibophelelayo: Iiteyiphu ezibophelelayo zeTransformer ziquka iiteyiphu zomqhaphu, iiteyiphu zokucinezela, iiteyiphu ezinemingxuma ezingenayo-weft ezinemingxuma, iiteyiphu zeglasi, iiteyiphu zepolyester, njl.

5. Ubume bezinto eziphathekayo kunye nezixhobo

Kwi-transformer, kukho kwakhona izinto zokwakha kunye nezixhobo. Izinto zokwakha zidlala ikakhulu imisebenzi yenkxaso ye-transformer, isekethe yemagnethi, ukuqinisa isekethe, i-transformer insulating liquid packaging, njl., kubandakanywa iziqeshana, iitanki zeoli, iiradiyetha, i-oyile conservators, njl. Izinto eziphambili ziyi-Q235 intsimbi, intsimbi engeyiyo-magnetic. isoloko isetyenziselwa ukutyhutyha indawo yesigqubuthelo setanki yamafutha ukunciphisa imisinga yeeddi. Ukongezelela, insimbi engeyiyo i-magnetic okanye i-high-grade steel ngamanye amaxesha isetyenziswa ngaphakathi komzimba we-transformer.

Izincedisi zeTransformer ikakhulu zinemisebenzi yokubeka iliso kunye nokukhusela ukusebenza. Iziguquli ezomileyo ziquka i-thermostats, iifeni, iziguquli, njl., kunye neenguqu ze-oyile ziquka ii-relays zegesi, i-thermostats, i-valve yokunciphisa uxinzelelo, i-tap switches, njl. Ezinye izincedisi zifunwa ngabathengi. cebisa.

Umthombo: Isangqa seTransformer