Izinto eziyinhloko zomzimba we-transformer zihlanganisa izinto zokujikeleza kazibuthe, izinto zokujikeleza, izinto zokuvikela, izinto zokwakha, njll.

Izinto eziyinhloko zomzimba we-transformer zihlanganisa izinto zokujikeleza kazibuthe, izinto zokujikeleza, izinto zokuvikela, izinto zokwakha, njll. Ukusetshenziswa kwempahla ethile kanye nezigaba yilezi:

1. I-Silicon steel sheet

Ku-transformer, izidingo zokusebenza kwensimbi ye-silicon ikakhulukazi:

①Ukulahleka kwensimbi ephansi, okuyinkomba ebaluleke kakhulu yekhwalithi yamashidi ensimbi ye-silicon. Wonke amazwe ahlukanisa amabanga ngokwenani lokulahlekelwa kwensimbi. Lapho ukulahleka kwensimbi kuphansi, izinga eliphezulu liyakhuphuka.

②Amandla kazibuthe wokungeniswa (i-magnetic induction) aphakeme ngaphansi kwenkundla kazibuthe eqinile, enciphisa umthamo nesisindo sengqikithi yensimbi yemoto kanye ne-transformer, futhi ilondoloza amashidi ensimbi ye-silicon, izintambo zethusi nezinto zokuvikela.

③Ingaphezulu libushelelezi, liyisicaba futhi lifana ngokuqina, okungathuthukisa isici sokugcwalisa somgogodla wensimbi.

④Inokubhoboza okuhle futhi kulula ukuyicubungula.

⑤Ukunamathela kanye nokushisela kwefilimu evikela ingaphezulu kuhle, okungavimbela ukugqwala futhi kuthuthukise impahla yokubhoboza.

⑥ Ngokuyisisekelo akukho ukuguga kazibuthe.

Ukwahlukaniswa kanye nencazelo yebanga le-silicon steel sheet

Ama-transformer ngokuvamile asebenzisa amashidi ensimbi ye-silicon egoqelwe okusanhlamvu ukuze aqinisekise amazinga awo okusebenza kahle kwamandla angalayishi. Ishidi lensimbi le-silicon eligoqelwe okusanhlamvu lingahlukaniswa libe ishidi le-silicon yensimbi evamile egoqelwe okusanhlamvu, ishidi lensimbi le-silicon elinamandla kazibuthe (noma ishidi lensimbi elinozibuthe elingenisayo), kanye neshidi lensimbi le-silicon elifaka amaphuzu ngokuya ngezakhiwo. kanye nezindlela zokucubungula. Imvamisa, ngaphansi kwendawo kazibuthe eshintshanayo (inani eliphakeme) elingu-50Hz no-800A, ishidi lensimbi ye-silicon ene-polarization encane kazibuthe B800A=1.78T~1.85T etholwe umgogodla wensimbi libizwa ngokuthi ishidi lensimbi le-silicon elijwayelekile, elichazwa ngokuthi "CGO", kanye ne-B800A=1.85T noma ngaphezulu Umehluko omkhulu phakathi kwensimbi ye-Hi-B nensimbi ye-silicon evamile yilokhu: i-Gaussian orientation texture ye-Hi-B steel Izinga le-silicon steel liphezulu kakhulu, okungukuthi, ukuqondanisa kwezinhlamvu ze-silicon steel isiqondiso samagnetization esilula siphezulu kakhulu. Embonini, inqubo ye-recrystallization yesibili isetshenziselwa ukwakha amashidi ensimbi ye-silicon enokuqukethwe kwe-silicon engu-3%. Ukuma okusanhlamvu kwensimbi ye-Hi-B kuphezulu kakhulu. Ukuchezuka okumaphakathi ukusuka lapho kuginqika khona kungu-3°, kuyilapho okweshidi lensimbi le-silicon elivamile kungu-7°, ukuze insimbi ye-Hi-B ibe nokufinyeleleka okuphakeme kazibuthe, ngokuvamile i-B800A yayo ingafinyelela ngaphezu kuka-1.88T, okuthuthukisa ukuthungwa kokuma kwe-Gaussian kanye Ukungena kwe-magnetic kunciphisa ukulahlekelwa kwensimbi. Esinye isici sensimbi ye-Hi-B ukuthi ukunwebeka okunwebekayo kwefilimu yengilazi kanye nokufakwa kwe-insulating okunamathiselwe ngaphezulu kweshidi lensimbi kungu-3~5N/mm2, okungcono kune-1 ~ 2 N/mm2 yensimbi ejwayelekile ye-silicon. ishidi. Isendlalelo se-tension ephezulu sinciphisa ububanzi besizinda kazibuthe futhi sinciphisa ukulahlekelwa okungavamile kwamanje kwe-eddy. Ngakho-ke, insimbi ye-Hi-B inenani eliphansi lokulahlekelwa kwensimbi kuneshidi lensimbi le-silicon eligxile okusanhlamvu.

Ishidi lensimbi elimakwe nge-laser lisekelwe ensimbi ye-Hi-B, ngobuchwepheshe be-laser beam irradiation, indawo engaphezulu iyacindezelwa kancane, i-axis kazibuthe iyacwengwa futhi, futhi ukulahleka kwensimbi okuphansi kufinyelelwa. Amashidi ensimbi e-silicon ephawulwe nge-laser awakwazi ukukhishwa, ngoba umphumela wokwelashwa kwe-laser uzonyamalala uma izinga lokushisa likhuphuka.

Ngokuvamile kuzungeze i-1.56T, okucishe kube ngu-20% ehluke ku-saturation flux density yeshidi lensimbi ye-silicon evamile engu-1.9T, ngakho-ke ukuminyana kwe-design flux ye-transformer nakho kudinga ukuncishiswa ngo-20%. Ukuminyana kwe-design flux yama-amorphous alloy oil transformers ngokuvamile kuba ngaphansi kuka-1.35T. Ukuminyana kazibuthe kwedizayini yecrystalline alloy dry change ngokuvamile kuba ngaphansi kuka-1.2T.

2) Imichilo ye-amorphous aggregate core iyazwela ekucindezelekeni. Ngemuva kokuthi ama-core strips egcizelelwe, ukusebenza okungenamthwalo kulula ukuwohloka. Ngakho-ke, ukunakwa okukhethekile kufanele kukhokhwe esakhiweni. I-core kufanele imiswe kuhlaka lokusekela kanye nekhoyili. Ithwala amandla ayo adonsela phansi, futhi ngesikhathi esifanayo, ukunakwa okukhethekile kufanele kukhokhwe ngesikhathi senqubo yomhlangano, umgogodla wensimbi awukwazi ukucindezelwa, futhi ukushaya nezinye izindlela kufanele kuncishiswe.

3) I-Magnetostriction icishe ibe ngu-10% enkulu kunaleyo yamashidi ensimbi ye-silicon evamile, ngakho-ke kunzima ukulawula umsindo wayo, okubuye kube esinye sezizathu eziyinhloko zokunciphisa ukukhuthazwa okusabalele kwama-amorphous alloy transformers. Umsindo we-transformer ubeka phambili izidingo eziphakeme, ezihlukaniswe zibe izindawo ezibucayi nezindawo ezingazweli, futhi izidingo zezinga lomsindo zibekwe phambili ngendlela ehlosiwe, edinga ukuncishiswa okuqhubekayo kokuminyana kazibuthe komklamo oyinhloko.

I-4) I-amorphous alloy strip mncane, inobukhulu obuyi-0.03mm kuphela, ngakho-ke ayikwazi ukwenziwa ibe yifomu le-lamination njengeshidi lensimbi ye-silicon evamile, kodwa ingenziwa kuphela ibe yinsimbi ehlanganisiwe. Ngakho-ke, isakhiwo esiyinhloko sensimbi sabakhiqizi be-transformer abavamile asikwazi ukucutshungulwa ngokwabo. Ukukhishwa ngaphandle, okuhambisana nesigaba esingunxande se-coiled iron core strip, ikhoyili ye-amorphous alloy transformer ngokuvamile nayo yenziwe ibe isakhiwo esingunxande;

5) Izinga lendawo alanele. Njengamanje, ithengwa kakhulu kwamanye amazwe imichilo ye-amorphous alloy evela ku-Hitachi Metals, futhi ukwenziwa kwasendaweni kancane kancane kuyabonakala. E-China, i-Antai Technology ne-Qingdao Yunlu ine-amorphous alloy broadband (213mm, 170mm kanye ne-142mm). , futhi kusekhona igebe elithile phakathi kokusebenza kwayo nokuzinza kwemigqa engenisiwe.

6) Ubude be-strip obukhulu bukhawulelwe. Ubude obukhulu be-peripheral strip yangaphandle yomugqa wengxubevange ye-amorphous esigabeni sokuqala nawo bulinganiselwe kakhulu ngenxa yokukhawulelwa kosayizi wesithando somlilo. Kodwa-ke, isixazululiwe njengamanje, futhi ama-alloys amorphous anobude obuyi-peripheral strip obungu-10m angakhiqizwa. I-iron core frame ingasetshenziswa ukwenza i-3150kVA nangaphansi kwe-amorphous alloy dry change kanye no-10000kVA nangaphansi kokushintshwa kukawoyela we-amorphous alloy.

Ngokusekelwe kumphumela omuhle kakhulu wokonga amandla wama-amorphous alloy transformers, okuhambisana nokukhuthazwa ukongiwa kwamandla kazwelonke kanye nokunciphisa ukungcola kanye nochungechunge lwezinqubomgomo, isabelo semakethe sama-amorphous alloy transformers siyakhula, futhi kucatshangelwa umugqa we-amorphous alloy (okwamanje u-26.5 yuan ) /kg) Intengo icishe iphindwe kabili kunaleyo yamashidi ensimbi ye-silicon evamile (30Q120 noma 30Q130), futhi igebe elinethusi lincane kakhulu. Uma kucatshangelwa ikhwalithi yemikhiqizo yegridi yamandla kanye nezidingo zokubhida, ama-amorphous alloy transformers ngokuvamile asebenzisa abaqhubi bethusi. Uma kuqhathaniswa namashidi ensimbi ye-silicon evamile, izikhala eziyinhloko zezindleko zama-amorphous alloy transformers zimi kanje:

1) Ngenxa yesakhiwo somgogodla wesilonda, isakhiwo sekholomu emihlanu yesigaba sesithathu kufanele samukelwe uhlobo lwe-transformer core, olunganciphisa isisindo sohlaka olulodwa lohlaka futhi lunciphise ubunzima bokuhlanganisa. Isakhiwo sekholomu emihlanu yezigaba ezintathu kanye nesigaba sesithathu sekholomu isakhiwo sinezinzuzo kanye nokungalungi kwazo ngokwezindleko. , Njengamanje, abakhiqizi abaningi basebenzisa isakhiwo sekholomu emihlanu yesigaba sesithathu. Okuthengiwe okuthengiwe kwensimbi yohlaka olulodwa kuboniswa kuMfanekiso 2:

2) Njengoba ingxenye yesiphambano sesiqu singunxande, ukuze kugcinwe ibanga le-insulation lilingana, amakhoyili kagesi aphezulu naphansi nawo enziwa abe isakhiwo esihambisanayo esingunxande.

1) Njengoba i-core design density kazibuthe ingaphansi ngo-25% kunaleyo ye-silicon steel sheet transformers evamile, futhi i-lamination coefficient yomgogodla wayo icishe ibe ngu-0.87, ephansi kakhulu kunaleyo ye-silicon steel sheet transformer evamile engu-0.97, umklamo wayo unqamule- indawo yesigaba idinga ukuba nkulu kunaleyo yama-silicon steel sheet transformers evamile. Uma inkulu kuno-25%, i-perimeter ehambisanayo yamakhoyili kagesi aphezulu naphansi nayo izokwenyuka ngokufanele. Ngesikhathi esifanayo, kuyadingeka futhi ukucabangela ukwanda kobude bekhoyili ye-voltage ephezulu nephansi. Ukuqinisekisa ukuthi ukulahlekelwa komthwalo wekhoyili akuguquki, indawo ye-cross-sectional yocingo idinga ukuba Ngokuhambisanayo, okuqukethwe kwethusi kwama-amorphous alloy transformers cishe ku-20% ephakeme kunaleyo ye-transformers evamile.

3. Izinsiza Zesekethe

Uhlolojikelele

Umjikelezo wangaphakathi we-transformer ikakhulukazi wakhiwe ngama-windings (owaziwa nangokuthi amakhoyili). Ixhunywe ngokuqondile kugridi yamandla yangaphandle futhi iyingxenye eyinhloko ye-transformer. Isifunda sangaphakathi se-transformer ngokuvamile senziwe ngama-wire windings. Izintambo zethusi kanye nezintambo ze-aluminium zihlukaniswe zibe izintambo eziyindilinga, izintambo eziyisicaba (ezingase ziphinde zihlukaniswe zibe izintambo ezilodwa, izintambo ezihlangene kanye nezintambo eziguqulwayo), ama-conductor we-foil, njll ngokusho kokuma kwe-cross-sectional yezintambo. izingqimba, futhi ekugcineni bakhe ikhoyili iyonke. Ngakho-ke, izinto eziyinhloko zomqhubi wesifunda se-transformer ziyithusi ne-aluminium.

3.1 Ukuqhathaniswa kwezimpawu zethusi ne-aluminium

Kokubili ithusi ne-aluminium yizinto zensimbi ezine-conductivity kagesi enhle futhi zivame ukusetshenziselwa ukwenza amakhoyili e-transformer. Umehluko wezakhiwo ezibonakalayo uboniswa kulelithebula elilandelayo:

3.2 Ukuqhathaniswa kokusebenza kwezintambo ze-copper-aluminium kuma-windings e-transformer

Umehluko we-copper-aluminium transformer nawo unqunywa umehluko wezinto ezibonakalayo, ohlanganiswe kulezi zici ezilandelayo:

1) I-resistivity yama-conductor yethusi cishe i-60% yalawo abaqhubi be-aluminium. Ukuze kuzuzwe ukulahlekelwa okufanayo kanye nezidingo zokukhuphuka kwezinga lokushisa, indawo ye-cross-sectional ye-aluminium conductors okufanele isetshenziswe ingaphezu kuka-60% enkulu kunaleyo yabaqhubi bethusi, ngakho-ke umthamo ofanayo kanye nemingcele efanayo iyadingeka. Umthamo we-aluminium conductor transformer uvame ukuba mkhulu kune-copper conductor transformer, kodwa indawo yokushisa ukushisa kwe-transformer nayo yanda ngalesi sikhathi, ngakho-ke ukuphakama kwamafutha kuphansi;

2) Ubuningi be-aluminium cishe bungama-30% kuphela wethusi, ngakho-ke ama-transformer okusabalalisa ama-aluminium alula kune-copper conductor distribution transformers;

3) Iphuzu lokuncibilika lekhondatha ye-aluminium liphansi kakhulu kunelekhondatha yethusi, ngakho-ke umkhawulo wokuphakama kwezinga lokushisa we-short-circuit current ngu-250 ℃, ongaphansi kuka-350 ℃ we-copper conductor. Inkulu, ngakho-ke ivolumu nayo inkulu kune-conductor transformer yethusi;

I-4) Ukuqina komqhubi we-aluminium kuphansi, ngakho-ke i-surface burr kulula ukuyiqeda, ngakho-ke ngemva kokwenziwa kwe-transformer, amathuba okuba i-inter-turn noma i-inter-layer short circuit ebangelwa i-burr iyancipha;

5) Ngenxa yokuqina okuphansi namandla acindezelayo amakhondatha e-aluminium namandla angenamandla emishini, ama-aluminium conductor transformer awakwazi ukujikeleza njenge-copper conductor transformer. Umkhawulo wokucindezeleka we-conductor ngu-1600kg / cm2, futhi umthamo wokuthwala uthuthukiswa kakhulu;

I-6) Inqubo ye-welding phakathi komqhubi we-aluminium kanye nomqhubi wethusi impofu, futhi ikhwalithi ye-welding ye-joint akulula ukuqinisekiswa, okuthinta ukuthembeka komqhubi we-aluminium ngezinga elithile.

7) Ukushisa okukhethekile kwekhondatha ye-aluminium kungu-239% walokho komqhubi wethusi, kodwa uma kucatshangelwa umehluko wokuminyana nokuklama ukuminyana kagesi phakathi kwakho kokubili, umehluko wangempela wesikhathi esishisayo phakathi kwakho kokubili awumkhulu njengokushisa okuqondile. umehluko. Umthamo wesikhashana wokulayisha ngokweqile wama-transformer ohlobo olomile unomphumela omncane.

4. Insulation impahla

Uhlolojikelele

Ukuthembeka kanye nempilo yesevisi ye-transformer, noma kunjalo, kuncike kakhulu ekusetshenzisweni kwe-insulating. Izinto zokuvikela, ezaziwa nangokuthi ama-dielectrics, ziyizinto ezine-resistive ephezulu kanye ne-conductivity ephansi. Izinto zokufaka i-insulating zingasetshenziswa ukuhlukanisa amakhondaktha ashajiwe noma anamandla ahlukene, okuvumela okwamanje ukuthi agezele ohlangothini oluthile. Emikhiqizweni ye-transformer, izinto zokuvikela i-insulating nazo zidlala indima yokukhipha ukushisa, ukupholisa, ukusekela, ukulungiswa, ukucisha i-arc, ukuthuthukiswa okungenzeka kwe-gradient, ukumelana nomswakama, ukumelana nesikhutha nokuvikela umqhubi. Ngaphansi kwesenzo se-voltage ye-DC, i-current encane kakhulu kuphela egeleza ku-insulating material. Ukumelana kwayo (kubhekiselwa ku-resistivity yevolumu emoyeni) iphakeme ngokuqhathaniswa, ngokuvamile i-108~1020Ω·cm (i-resistivity ka-conductor ingu-10-6~10-3Ω·cm, futhi ukumelana kwe-semiconductor kungu-10-3~ 108Ω cm).

I-insulating material inokumelana okukhulu kakhulu ne-DC yamanje. Ngenxa yokumelana kwayo okuphezulu, ngaphansi kwesenzo se-voltage ye-DC, ayihambisani neze ngaphandle kwendawo encane kakhulu evuzayo yamanje; ngenkathi inamandla ku-AC yamanje. Amandla kagesi nawo ngokuvamile abhekwa njengongaconductive. Ukuphakama kwe-resistivity ye-insulating material, ngcono izakhiwo zayo zokuvikela.

Izinto zokuvikela i-insulating zisetshenziswa kuma-transformer ukuze zihlukanise izingxenye ezihambisayo ukusuka komunye nomunye ukuya phansi (amandla we-zero). Lapho zisetshenziswa ekusekeleni okuhlukahlukene, kufanele futhi zibe nezakhiwo ezinhle zemishini. Ngaphezu kwalokho, izinto zokuvikela i-insulating nazo zidlala ezinye izindima, njengokupholisa, ukulungisa, ukugcinwa kwamandla, ukucisha i-arc, ukuthuthukisa i-gradient engaba khona, umswakama-ubufakazi, i-mildew-proof nokuvikela ama-conductor.

Ngokuvamile, izinto zokuvikela ziwela ezigabeni ezintathu:

I-1) Izinto zokuvikela igesi: Ngaphansi kokushisa okujwayelekile nokucindezela, amagesi omile ajwayelekile anezindawo ezinhle zokuvikela, njengomoya, i-nitrogen, i-hydrogen, i-carbon dioxide, i-sulfur hexafluoride, njll. Phakathi kwazo, i-air and sulfur hexafluoride isetshenziswa kuma-transformers. kabanzi;

2) Izinto zokuvikela uketshezi: Izinto zokuvikela uketshezi ngokuvamile ziba khona ngendlela yamafutha, eyaziwa nangokuthi uwoyela ovikelayo. Njengamafutha amaminerali, amafutha emifino, ama-synthetic esters, njll;

3) Izinto zokuvikela eziqinile: njengopende wokuvikela, insulating glue, insulating paper, insulating cardboard, amakhadibhodi kathayela, amapulasitiki kagesi namafilimu, amalaminate kagesi (izinduku, amashubhu), i-epoxy resin ebunjiwe, i-porcelain kagesi, irabha, imikhiqizo ye-mica, njll.

4.1 Amafutha okuvikela ukushisa

Amafutha e-insulating abonakala ngamandla kagesi aphezulu, umbani ophezulu, indawo ephansi yokuqandisa, izinga lokushisa lokusebenza ngaphansi kwesenzo se-oxygen, izinga lokushisa eliphezulu kanye nensimu kagesi enamandla, engeyona enobuthi, engagqwali, i-viscosity ephansi, i-fluidity enhle nokunye. Isetshenziswa kabanzi emikhiqizweni kagesi efana nama-transformers, ama-switch switch kawoyela, ama-capacitor nezintambo, futhi idlala indima yokufakwa kwe-insulation, ukupholisa, ukufakwa kanye nokugcwalisa. Ngaphezu kwalokho, iphinde idlale indima yokucima i-arc ekushintsheni kwamafutha kanye nokugcinwa kwamandla kuma-capacitor.

Amafutha afaka i-insulating adlala indima emibili yokufakelwa kanye nokupholisa ku-transformer ngesikhathi esifanayo;

Amafutha e-insulating okwamanje ngokuvamile ahlukaniswe ngezigaba ezilandelayo:

1) Amafutha amaminerali: njengamafutha e-transformer, uwoyela wokushintsha, uwoyela we-capacitor, uwoyela wekhebula;

2) Amafutha okwenziwa: njenge-dodecylbenzene, uwoyela we-silicone, i-synthetic ester, njll.;

3) Amafutha emifino;

4.2 I-Epoxy resin

I-Epoxy resin iyinhlanganisela ye-polymer. I-resin ibonakala ngento ephilayo eqinile, ecishe iqine noma eqinile enesisindo esinganqunyelwe semolekyuli (imvamisa iphakeme), ukuthambekela kokugeleza lapho ingaphansi kwengcindezi, imvamisa ukuthambisa noma ukuncibilika kobubanzi, kanye nesigaba esiqinile esivame ukuncibilika. iveza umumo ofana negobolondo. Inezici ezilandelayo eziyisisekelo:

1) Iketango lamangqamuzana lide kakhulu, iketango ngalinye liqukethe amakhulukhulu noma amashumi ezinkulungwane zama-athomu, axhumene ngokuhlanganyela;

2) Iketango elide lamangqamuzana lakhiwe iyunithi encane ephindaphindayo, okungukuthi, i-chain link, futhi inani lezixhumanisi zamaketanga ku-molecule libizwa ngokuthi i-degree of polymerization;

3) Ingqikithi yamandla e-intermolecular yama-macromolecules ngokuvamile idlula amandla esibopho samakhemikhali phakathi kwama-athomu ku-molecule, ukuze izinhlanganisela ze-polymer zibe nochungechunge lwezimpawu: isibonelo, ayikho i-polymer yegesi, inqubo yokuchithwa kwe-polymer ihamba kancane, njll. kukhona ukuxhumanisa phakathi kwama-molecule, Lesi sici sihluke nakakhulu.

I-epoxy resin ibhekisela kuma-oligomers aqukethe amaqembu asebenzayo e-epoxy. Ama-epoxy resins aqala ukuvela ngo-1891. Ngemva kuka-1947, izinkampani eziningi e-United States naseSwitzerland zenza ngempumelelo i-bisphenol A epoxy resins ezimbonini. izwe lami laqala ukukhiqiza ngo-1956.

Izakhiwo zokufakwa kukagesi zezinto ze-epoxy zivelele kakhulu. Uma singafakwanga isigcwalisi, i-EB yomkhiqizo olashiwe ingaphezulu kuka-16MV/m, i-pV ingaphezulu kuka-1011Ω·m, i-εr ingu-3 ukuya ku-4, futhi i-tanδ icishe ibe ngu-0.002 ngaphansi kwefrikhwensi yamandla. Ngakho-ke, indandatho engu-20% yezinhlayiya ze-oksijeni zisetshenziselwa ukufakwa kukagesi kanye ne-elekthronikhi, njengopende we-epoxy impregnating njengopende we-B-class insulating, ufaka ama-motor stator windings amancane naphakathi; upende we-epoxy-solvent-free usetshenziselwa ukufakwa kwe-vacuum yama-motor stator windings amakhulu; ama-laminates (amapuleti, amashubhu, izinduku) asetshenziswa njengama-slot wedges kanye nama-spacers ama-motor, izinduku zokusebenza zokushintshwa kwe-high-voltage; ama-adhesives asetshenziselwa ukubopha ama-high-voltage electric porcelain bushings; ama-castable asetshenziselwa ukuhlukaniswa kwe-disc ku-sulphur hexafluoride ehlanganiswe ngokugcwele nezinto zikagesi ezihlanganisiwe (GIS). Izingxenye ezinjengama-insulators, ama-transformer kanye nama-capacitor e-ceramic aphezulu-voltage. Njengamanje, amagama emikhiqizo yama-epoxy resins noma ama-epoxy resins akhiqizwa e-China awakabi umfaniswano okwamanje. Amagama abakhiqizi abahlukene be-epoxy resin emhlabeni wonke nawo ahlukile futhi adinga ukukhonjwa ngophawu lokuthengisa.

Ama-epoxy resins angama-oligomers futhi angasetshenziswa kuphela ngemuva kokwelashwa. I-ejenti elaphayo ingasabela nge-epoxy resin ukuze ixhumanise ama-molecule e-resin asuka esakhiweni esiwumugqa aye esakhiweni esiyinqwaba. Amaphromotha/ama-catalyst anganciphisa amandla okwenza kusebenze okusabela futhi angakhuthaza/alungise inqubo yokusabela kwejeli ye-castable. I-ejenti elaphayo isebenzisa i-hydrogen esebenzayo equkethwe kuyo ukwenza ukusabela kokwengeza okuvula indandatho neqembu elisebenzayo le-epoxy kunhlaka ukuze bathole ukwelashwa. I-hydrogen esebenzayo ithi -NH2, -NH-, -COOH, -OH kanye -SH kusisebenzeli esilaphayo noma i-accelerator. ku-hydrogen. Ama-ejenti okwelapha asetshenziswa kakhulu ama-amine nama-acid anhydride. Amanye ama-ejenti okwelapha adinga ama-accelerator/ama-catalyst, amanye adinga izimo zokushisa eziphakeme, kanti amanye angasabela ngobudlova emazingeni okushisa aphansi. Ama-ejenti ahlukene okwelapha nawo azoholela ekuhlukeni okukhulu kwezakhiwo zemikhiqizo eselashiwe, enomthelela obalulekile ezindaweni zokugcina zomkhiqizo. Ngakho-ke, kubaluleke kakhulu ukuklama nokukhetha i-ejenti yokwelapha ohlelweni lokwakhiwa kwe-epoxy resin.

I-epoxy insulation isetshenziswa kuma-ome-type transformer futhi iyintuthuko entsha eminyakeni engama-40 edlule. Impilo yokuklama ikhoyili ye-transformer iyadingeka ukuze ifinyelele eminyakeni engama-30, futhi izinga lokumelana nokushisa kufanele lifinyelele ebangeni lika-F. Kunzima ngezinto ezijwayelekile ukuhlangabezana nezidingo.

Kulokhu, kuyadingeka ukuklama, ukugcwalisa, ukuhlola nokuqinisekisa izinto ezisetshenziswayo kanye nezinhlelo zazo zokuzikha nezinqubo ukuze kutholwe umphumela oyifunayo. Ku-transformer ye-resin-insulated dry-type, isistimu ye-epoxy resin yenziwa ngokuphonsa noma ukucwiliswa, bese iphulukiswa ngokushisa ukuze yenze ukufakwa kwamakhoyili (okungukuthi, ukufakwa kwe-longitudinal). Phakathi nakho konke ukusebenza kwe-transformer yohlobo olomile, i-epoxy resin insulation kumele iphinde iqinisekise ukufakwa kukagesi kwekhoyili namandla omshini, futhi ikhiphe ukushisa ngaphakathi kwekhoyili ngokusebenzisa i-thermal conduction.

Ubuthakathaka bayo obukhulu ukungalungiseki kanye nokungalungiseki kokulimala nokulimala kokufakwa kwe-resin (ngokuvamile amaphutha enqubweni yokukhiqiza kanye nomonakalo ohlelweni lokusebenza). Ngakho-ke, ukugwema ukuqhekeka kwe-insulation eqinile, ukugwema ukonakala, nokugwema ukukhipha ingxenye (okungukuthi, ukukhipha ingxenye) kubaluleke kakhulu, futhi kuba ukhiye wobuchwepheshe bokukhiqiza ukufakwa kwezinto eziqinile, futhi kuyingqikithi yokuncintisana phakathi kwabakhiqizi.

Ngenxa yokukhuphuka kwezinga lokushisa okubangelwa ukulahleka ngesikhathi sokusebenza kwe-transformer, ukufakwa kwe-resin kusebenza ekushiseni okuphezulu isikhathi eside (njenge-F-class transformer, izinga lokushisa eliphezulu eliklanyelwe ukusebenza ngokuvamile liba ngu-140 ℃), futhi i-transformer ingase ibe sezingeni lokushisa eliphezulu ngaphambi kokuthunywa nangesikhathi sokulungiswa. Izinga lokushisa eliphansi (elifana -30 ℃), kanye ne-transformer izoba ngaphansi kokushaqeka okukhulu kukagesi kokushaqeka kombani we-voltage ephezulu noma isifunda esifushane nganoma yisiphi isikhathi. Amakhoyili afakwe i-resin-insulated kufanele akwazi ukuzivumelanisa nalezi zinguquko, futhi akwazi ukumelana noma ukumelana nama-short-circuit electrodynamic shock emazingeni okushisa aphezulu kakhulu naphansi. Ngakho-ke, izidingo eziqine ngokwedlulele zibekwe endaweni eshisayo, yemishini kanye nekagesi yezinhlelo ze-epoxy insulation.

Njengamanje kunezinhlobo ezimbili zezinhlelo ze-insulating material for resin cast transformers, eyodwa "i-resin ehlanzekile + yokugcwalisa ingilazi ye-fiber reinforcement ephezulu", kanti enye "i-resin quartz powder casting + prepreg glass mesh reinforcement yendawo".

I-insulation system (okungukuthi, i-insulation structure) ihlanganisa insimu ebanzi kunohlelo lwe-insulation material. Kubhekiselwa ekwakhiweni kwemishini kagesi (noma izingxenye zayo ezizimele) iyonke, okubandakanya hhayi kuphela izinto zokufakelwa kanye nezinhlanganisela zazo, kodwa futhi nokufaka ama-conductor. Noma ubudlelwano phakathi kozibuthe, ubudlelwano nenkundla kagesi, ubudlelwano phakathi kokwahlukanisa nendawo ezungezile (igesi noma uketshezi nezimo zalo, ukungcoliswa kwendawo, izimo zokukhipha ukushisa, amandla emishini noma imisebe, njll.), kanye ukuzivumelanisa nezimo kumapharamitha okusebenza wesistimu yamandla Kuyinto yokufakelwa. Ukugeleza komoya kanye nokukhishwa kokushisa ku-transformer yohlobo olomile, ingcindezi yokufakwa kwe-insulation, njll., konke kungaphakathi kobubanzi besistimu yokufaka ezocatshangelwa.

4.3 Iphepha le-insulation

Iphepha le-fiber yezitshalo lihlukaniswe nge-wood fiber, i-cotton fiber kanye ne-hemp fiber, okuvame ukusetshenziswa kakhulu yiphepha le-sulfate wood pulp fiber paper. I-Fir ne-Korean pine nezinye izinkuni ngokuyinhloko zakhiwe nge-cellulose, okuyinhlanganisela yemvelo ye-polymer. Indlela yokukhiqiza ye-insulating paper ithatha indlela yamakhemikhali, njengendlela ye-sulfate. Ngale ndlela, ingxenye eyinhloko yoketshezi lokupheka i-sodium sulfide (Na2S). I-sodium sulfide i-hydrolyzed ukuze ikhiqize i-sodium hydrogen sulfide ne-sodium hydroxide. I-cellulose iyasabela futhi iyincibilikise ku-lye. I-liquid yokupheka imnene, ngakho-ke isisindo samangqamuzana se-cellulose siyancipha kakhulu. Amaphepha avame ukusetshenziswa esitshalweni se-cellulose insulating kuma-transformer yilawa: iphepha lekhebula lamandla, iphepha lekhebula elinamandla kagesi kanye nephepha le-transformer inter-turn insulating.

1) Iphepha lekhebula: Iphepha lekhebula lenziwe nge-kraft pulp, amamaki angu-DL08, DL12, DL17, ubukhulu bungu-0.08mm, 0.12mm no-0.17mm, ngokulandelana, futhi ahlinzekwa ngama-roll. Ngemuva kokuthi iphepha lekhebula lifakwe ngamafutha e-transformer, amandla ayo omshini kanye namandla kagesi azothuthukiswa kakhulu. Isibonelo, amandla kagesi wephepha lekhebula lamandla emoyeni yi-6 ~ 9 × 103kV / m, futhi ngemva kokumisa nokucwilisa uwoyela we-transformer, amandla kagesi afinyelela ku-70 ~ 90 × 103kV / m. Inokuqina okwanele kwe-thermal futhi ivamise ukusetshenziswa njenge-insulation yama-winding kanye ne-interlayer insulation. Iphepha lekhebula lihlanganisa nephepha lekhebula lamandla kagesi aphezulu, iphepha lekhebula elingamandla kagesi aphansi, iphepha lekhebula elinomthamo omkhulu kanye nephepha le-crepe elivikelayo. Iphepha lekhebula le-high-voltage lifanele ama-transformers angu-110-330kV nama-transformers, ane-tangent yokulahlekelwa kwe-dielectric ephansi; iphepha lekhebula elinamandla aphansi lisetshenziselwa ukwahlukanisa izintambo zikagesi nama-transformer noma eminye imikhiqizo kagesi engu-35kV nangaphansi; i-insulating crepe paper yenziwe ngephepha lokuvikela likagesi. Yenziwe ngokucubungula imibimbi, futhi kukhona imibimbi eduze nendawo yayo enqamulayo, edonswa ihlukaniseke lapho yeluliwe. Ivamise ukusetshenziselwa ukugoqa ukwahlukanisa kwama-transformer acwiliswe ngamafutha, njengokugoqwa kwe-insulation of coil outlets, lead and electrostatic shielding devices; Iphepha lekhebula le-high-density liphinde lifake insulating Uhlobo lwephepha le-crepe, amandla kagesi aphakeme ngo-100% kuya ku-150% ngaphezu kwephepha elijwayelekile le-crepe, amandla emishini aphakeme ngo-50%, amandla kagesi aphezulu, ukumelana nowoyela kuhle, ukunwebeka kuhle, futhi kulula ukwelula. Ingasetshenziswa njengomthofu esikhundleni se-tape ene-varnish. kanye nokwahlukanisa kwezintambo nokugoba.

2) Iphepha locingo: Iphepha locingo nalo lenziwe nge-sulfate pulp, evame ukusetshenziswa ezintanjeni zocingo. Inamandla amancane emishini futhi ngokuvamile isetshenziswa njenge-insulation ephendukayo, i-layer insulation noma i-cover insulation yama-conductor.

I-3) Iphepha le-Capacitor: Iphepha le-Capacitor lihlukaniswe i-Class A kanye ne-Class B ngokuya ngezidingo zokusetshenziswa. Iphepha le-Capacitor le-Class A lisetshenziselwa i-metallized paper dielectric capacitor embonini ye-elekthronikhi. I-Class B isetshenziswa kakhulu njenge-interpole dielectric yama-capacitor amandla. Iphepha le-Capacitor libonakala ngokuqina okuphezulu nokuqina okuncane. Ngokuvamile, ama-transformer amanje avame ukusebenzisa iphepha le-capacitor, futhi ama-transformer awavamile ukusetshenziswa.

4) Iphepha eliboshiwe le-insulating: Iphepha eliboshiwe le-insulating lisetshenziswa njengephepha elisekelayo lephepha lokulinganisa, futhi iphepha lokulinganisa lisetshenziselwa ukuvunguza isilinda (ishubhu) kanye nomkhono we-capacitive, obonakala ngokuthi ukuphakama kokumuncwa kwamanzi kuphezulu. kunephepha lekhebula futhi liphansi kunePhepha lokufakela. Iphepha elinamathiselwe lihlukaniswe libe yi-single-side noma kabili-sided glued (phenolic noma epoxy resin), ephulukiswa ekushiseni okuphansi. Lapho iphepha elinamathiselwe lisetshenziselwa ukwenza ithubhu lephepha noma ucindezela i-laminate, iglue ekugcineni ilapheka lapho ishisa futhi icindezelwa. , I-roll ngokuvamile iyiteyipu yohlangothi olulodwa, futhi itheyiphu ecindezelwe iyiteyipu enamacala amabili. Ngaphezu kwalokho, kukhona nephepha elinamathiselwe ngedayimane (iphepha elinamathiselwe nge-mesh), elisetshenziselwa ukufakwa kwe-interlayer kwamakhoyili asongayo we-foil acwiliswe ngamafutha. Ngemuva kokuphulukisa, iqinisekisa ukunamathela phakathi kokufakwa ngaphakathi naphakathi kokufakwa kwe-insulation kanye ne-foil, ithuthukisa Amandla kanye nokungena kahle kwamafutha.

Iphepha elivamile le-transformer insulating lisetshenziswa kakhulu ephepheni lekhebula, i-crepe paper kanye ne-rhombus dispensing paper, elisetshenziswa kuma-transformer njenge-inter-turn insulation, i-inter-layer insulation, isibopho somthofu, njll. Imvamisa, amanani ezinhlobo ezahlukene zephepha lokuvikela imvelo akuhlukile. Izoba nkulu kakhulu, cishe ama-yuan angama-20/kg.

4.4 Izinto ezihlanganisiwe zikagesi

Amafilimu amancanyana kagesi nezinto eziyinhlanganisela kagesi zinezakhiwo ezinhle kakhulu ze-dielectric futhi zingezamathuluzi okuvikela amashidi amancane. Amafilimu kagesi ahlanganisa ifilimu ye-polyester kanye nefilimu ye-polyimide, engasetshenziswa futhi njenge-insulation yezintambo kanye nokufakwa kwe-interlayer kuma-transformer. Impahla ehlanganisiwe kagesi ingumkhiqizo oyinhlanganisela owenziwe ohlangothini olulodwa noma izinhlangothi ezimbili zefiber ehlanganisiwe yefilimu, engasetshenziswa njenge-interlayer insulation in transformers, ikakhulukazi kumakhoyili we-foil esilonda esomile, futhi amakhoyili ane-voltage ephansi ngokuvamile enziwa izinto ezihlanganisiwe. Ngemuva kokufakwa kwe-resin, isetshenziswa njenge-interlayer insulation. Izinto ezisetshenziswayo ezisetshenziswa kakhulu yi-DMD, GHG nokunye.

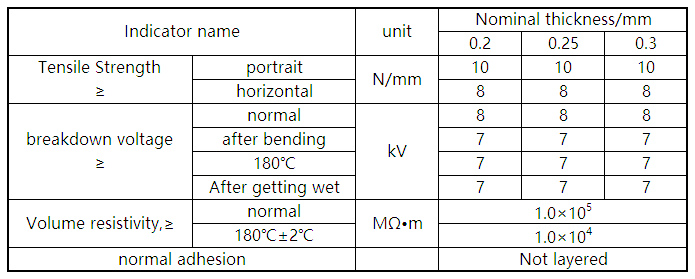

Igama eligcwele le-DMD i-polyester film polyester fiber non-woven soft composite material, ehlukaniswa nge-DMD ye-resin efakwe ngaphambili kanye ne-DMD engafakwanga ngaphambili. D) Inhlanganisela ethambile yezendlalelo ezintathu eyakhiwe. I-DMD ine-insulation kagesi enhle kakhulu, ukumelana nokushisa namandla emishini kanye nezakhiwo ezinhle kakhulu zokungena. I-DMD engakabi prepreg ingasetshenziswa njenge-interlayer insulation yama-transformer acwiliswe uwoyela, futhi i-prepreg DMD ingasetshenziswa njenge-interlayer insulation coil yamakhoyili amanxeba e-foil ane-voltage ephansi ku-Class F yohlobo loguquguqukayo olomile. Izinkomba zayo zokusebenza ezithize zikhonjiswe kuthebula elilandelayo:

Igama eligcwele le-GHG ifilimu ye-polyimide efakwe ngaphambili kwe-H-grade resin glass fiber soft composite material. Yizinto eziyinhlanganisela ezithambile ezinezendlalelo ezintathu ezenziwe ngendwangu yengilazi yefibre (G) enamathiselwe nhlangothi zombili zefilimu ye-polyimide (H). . Uma iqhathaniswa ne-DMD, inokumelana nokushisa okungcono futhi ingasetshenziselwa ukwahlukanisa phakathi kwamakhoyili enxeba le-foil ene-voltage ephansi ye-H-class insulation dry-type transformers.

Igama eligcwele le-NHN yi-polyimide film polyaramid fiber paper soft composite material. I-NHN njengamanje iyisivikelo sezinga eliphakeme kakhulu sengqimba emincane, enokumelana nokushisa okuhle kakhulu, izakhiwo ezinhle ze-dielectric, ukumuncwa kwamanzi amancane kanye nokumelana nomswakama okuhle kakhulu. Iyingxenye ye-insulating yekilasi H futhi ingasetshenziselwa ukufakwa kwe-interlayer kwama-transformer ohlobo olomile lwekilasi H. Imingcele yokusebenza kwayo ethile iboniswa kuthebula elilandelayo:

4.5 Amakhadibhodi afaka i-insulating

I-insulating paperboard yenziwe nge-kraft wood pulp papermaking ehlanzekile futhi ingasetshenziselwa izikhala zegebe likawoyela, ukuhlala kwegebe likawoyela, izihlukanisi, amashubhu ekhadibhodi, iphepha likathayela, ukufakwa kwejoka lensimbi, ukwahlukanisa isiqeshana kanye nokugcina amapuleti okucindezela okugoqa uphaya njll., ukujiya evamile 1.0mm, 1.5mm, 2mm, 3mm, 4mm, 6mm, amakhadibhodi insulating ihlukaniswe low-density amakhadibhodi, medium-density amakhadibhodi kanye high-density amakhadibhodi ngokusho kwabantu, low-density paper ngokuvamile ebizwa T3 soft cardboard. , ukuminyana kuphakathi kuka-0.75g/cm3 no-0.9g/cm3, amandla aphansi, futhi ngokuvamile asetshenziselwa ukugoba izingxenye noma ukwenza izingxenye ezinwebekayo ngemva kokumanzisa, njengokwenza ama-angle ama-angle, izingxenye ze-annular namashubhu ephepha athambile. Ikhadibhodi le-low density inezinga eliphezulu lokumunca uwoyela, ukwakheka okuhle, kodwa izici zemishini ezingezinhle; i-medium-density cardboard ngokuvamile ibizwa ngokuthi i-T1 cardboard, enobuningi obuphakathi kuka-0.95g/cm3 no-1.15g/cm3, esetshenziswa njengendawo yokuhlala, njll.; Ikhadibhodi elinomthamo omkhulu wekhadibhodi ngokuvamile libizwa ngekhadibhodi le-T4, elinesisindo esingu-1.15g/cm3 kuya ku-1.3g/cm3, futhi lisetshenziswa njengeshubhu lekhadibhodi elivikelayo, ipuleti lokucindezela elivikelayo kanye nendandatho yokugcina. Esakhiweni se-oil-board spacer esakhiwe ngamashubhu ephepha anezingqimba eziningi ezinama-voltage aphezulu, amakhadibhodi anothayela angasetshenziswa esikhundleni sama-cardboard struts ukwakha izikhala zikawoyela, ezingagcina izinto ezisetshenziswayo ngesisekelo sokuqinisekisa ukusebenza kokufakwa.

4.6 Ifilimu ye-polypropylene

Ifilimu ye-polypropylene yenziwe nge-polypropylene resin (PP) ekhishwe eshidini eliwugqinsi futhi yelulwe ngendlela. 0.92g/cm3. I-2) Inezindawo ezinhle zikagesi nokuzinza kwamakhemikhali, i-coefficient ye-dielectric ehlobene i-2 kuya ku-2.2, futhi ingcindezi yokuwohloka inkulu kune-150MV / m; 3) Inezici ezinhle zemishini, futhi amandla ayo aqinile makhulu kuno-100MPa; 4) Ingasetshenziswa isikhathi eside ku-125 ℃ futhi ingeye-E-class insulation; I-5) Ine-hydrophobicity kanye nekhono eliqinile lokulwa namanzi, futhi ingasetshenziselwa ukufakwa kwezintambo zama-transformer acwiliswe uwoyela.

4.7 Ezinye izinto zokuvikela ukushisa

Amafutha e-Transformer kanye nephepha le-insulating yizinto eziyinhloko zokuvikela amakhoyili e-transformer acwiliswe ngamafutha. I-resin, i-insulating paper, nezinto eziyinhlanganisela yizinto eziyinhloko zokuvikela amakhoyili ohlobo olomile. Ngaphezu kwalezi zinto, lezi zinto ezilandelayo zokuvikela zivame ukusetshenziswa kuma-transformers: (Ukhuni olunamanzi, i-laminate, upende ovikelayo, i-insulating glue, i-cotton tape, i-compression tape, ayikho i-weft tape, njll.

1) I-Laminate: I-laminate kagesi iyisivikelo esinezingqimba esenziwe ngephepha, indwangu kanye ne-veneer yokhuni njenge-substrate, ecwiliswe (noma eboshwe) ngezinamatheliso ezahlukene, futhi icindezelwe ngokushisa (noma igingqe). . Ngokwezidingo zokusetshenziswa, imikhiqizo e-laminated ingenziwa ibe yimikhiqizo enezinto ezinhle kakhulu zikagesi nezemishini, ukumelana nokushisa, ukumelana nowoyela, ukumelana nokukhunta, ukumelana ne-arc kanye nokumelana ne-corona. Imikhiqizo ye-laminate ikakhulukazi ihlanganisa ama-laminates, ukhuni olulayiniwe, amashubhu ahlotshisiwe, izinduku, ama-sleeve cores we-capacitor namanye amaphrofayili akhethekile. Izakhiwo zama-laminates zincike esimweni se-substrate ne-adhesive kanye nenqubo akhiwa ngayo. Ngokwezinto zokusetshenziswa ezihlukene kanye nezinamatheliso, ama-laminates ahlukaniswe abe ama-laminates avikelayo (i-paperboard, esetshenziselwa ukushintsha uwoyela), i-phenolic laminated paperboard (eyaziwa ngokuthi i-bakelite, i-paperboard efakwe nge-phenolic resin, esetshenziselwa ukushintsha uwoyela), ibhodi lendwangu ye-phenolic laminated (ukotini. Indwangu efakwe nge-phenolic resin, evame ukusetshenziselwa ukushintsha uwoyela), ibhodi lendwangu yengilazi epoxy (indwangu yengilazi yefiber ene-epoxy resin njenge-adhesive, ingasetshenziselwa ukuguqulwa okomile kwe-F grade noma ukuguqulwa kwamafutha), ibhodi lendwangu yengilazi ye-diphenyl ether eguquliwe (Indwangu ye-Glass fiber isebenzisa i-diphenyl ether resin eguquliwe njenge-adhesive, engasetshenziswa ekushintsheni okomile kwezinga le-H), ibhodi lendwangu yengilazi ye-bismaleimide (indwangu ye-glass fibre isebenzisa i-bismaleimide resin njenge-adhesive, Ingasetshenziselwa ukuguqulwa okomile kwezinga le-H). Ama-laminates ngokuvamile anamandla amahle okusebenza kanye nezakhiwo zokuhlukanisa, futhi avame ukusetshenziswa njenge-core clip insulation, izisekelo zangaphandle, njll. kuma-transformer.

2) I-insulation cylinder (ithubhu): Isilinda sokufakelwa ku-transformer sisetshenziswa ikakhulukazi phakathi kwamakhoyili angaphakathi nangaphandle, phakathi kwekhoyili nensimbi, ukuze ikhoyili efake uhlaka lwamathambo, futhi ucingo lulimale ngokuqondile kusilinda sokufakelwa. Ngesikhathi esifanayo, isilinda sokufakelwa singasetshenziselwa i-Insulation eyinhloko, ukwandisa inani lezikhala zamafutha ku-insulation main, futhi uqinise ukufakwa. Ngokwezinto ezahlukahlukene, ishubhu lokuvikela livame ukuhlukaniswa libe yishubhu lephepha le-phenolic (elivame ukusetshenziselwa ukushintsha uwoyela), ishubhu yendwangu yengilazi ye-epoxy (evame ukusetshenziselwa ukuguqulwa kwamafutha noma ukuguqulwa okomile kwebanga F), ishubhu yendwangu yengilazi ye-diphenyl ether eguquliwe (evame ukusetshenziswa ukushintsha uwoyela) Ukushintsha okomile kwezinga le-H), isilinda sepulasitiki esiqiniswe ngefayibha yengilazi (evame ukusetshenziswa ekushintsheni okomile kwezinga le-H), isilinda sendwangu yengilazi ye-bismaleimide (evame ukusetshenziswa ekushintsheni okomile kwezinga le-H), njll.

3) Ukhuni olufakwe elayiniwe: Ukhuni olune-laminated kagesi lwenziwa ngezingodo eziqinile zekhwalithi ephezulu, njenge-birch, beech, njll. Ngemva kokuphekwa kabili ku-70 ° C kuya ku-80 ° C, i-lignin acid namafutha ezinkuni ngokwawo ayasuswa, bese usika zibe izingcezu ngazinye 1 kuya 3 mm. Ngemuva kokoma, imbozwe nge-resin adhesive. Ngemuva kokwelashwa kwangaphambili, ihlanganiswa ngokuphindaphindiwe futhi ihlanganiswe. Inamandla amahle okuvikela amandla kanye namandla omshini. Ingasetshenziswa njenge-spacer, indandatho ye-engeli, njll ekushintsheni kwamafutha. .

1) Amateyipu abophayo: Amateyipu abopha i-transformer ahlanganisa amateyipu kakotini, amateyipu okucindezela, amateyipu angewona ama-mesh asemi-dry, amateyipu ezingilazi, amateyipu e-polyester, njll., asetshenziselwa ukubopha nokuqinisa insimbi namakhoyili.

5. Isakhiwo sezinto ezibonakalayo nezesekeli

Ku-transformer, kukhona nezinto zokwakha nezinsiza. Izinto zokwakha zidlala ikakhulukazi imisebenzi yokwesekwa kwe-transformer, isekethe kazibuthe, ukuqinisa isekethe, i-transformer insulating liquid packaging, njll., okuhlanganisa iziqeshana, amathangi kawoyela, ama-radiator, okonga uwoyela, njll. Izinto eziyinhloko ezensimbi ye-Q235, insimbi engeyona i-magnetic. kuvame ukusetshenziselwa ukuqhuma kwe-outlet yekhava yethangi likaphethiloli ukunciphisa imisinga ye-eddy. Ngaphezu kwalokho, insimbi engeyona i-magnetic noma insimbi yezinga eliphezulu ngezinye izikhathi isetshenziswa ngaphakathi komzimba we-transformer.

Izesekeli ze-Transformer ikakhulukazi zinemisebenzi yokuqapha nokusebenza kokuvikela. Iziguquli ezomile zihlanganisa ama-thermostat, amafeni, ama-transformer, njll., futhi iziguquli zikawoyela zihlanganisa ama-relay egesi, ama-thermostats, ama-valve okusiza ukucindezela, amaswishi kampompi, njll. Ezinye izisetshenziswa zidingeka amakhasimende. phakamisa.

Umthombo: I-Transformer Circle