I-cut to length line li iyithuluzi elikhethekile lokukhiqiza i-transformer core, isizukulwane sethu sakamuva se-cross shear line. Lo mugqa wokukhiqiza usetshenziselwa ukugunda, i-O punching kanye ne-V notch ye-transformer core sheet.

Iphuzu elikhethekile lalo mugqa ukuthi i-punch eyodwa ye-O kanye notch eyodwa ye-V; Ingakwazi ukukhiqiza izingcezu ze-transformer core ezinezinyathelo ezingu-3, 5, 7 isiqondiso esiqondile kanye nezinyathelo ezingu-3, 5, 7 endaweni evundlile.

Ngemuva kokuthi ikhoyili yeshidi lensimbi ye-silicon igxotshiwe futhi isikwe esimweni esithile nosayizi yilo mugqa wokukhiqiza, umsebenzi wokuhlukanisa nomsebenzi wokuqeda uqedwa ekupheleni komugqa wokukhiqiza, futhi unamathiselwe ngokuzenzakalelayo kumakholomu angu-2 futhi usetshenziselwe umgogodla. umhlangano.

Lo mugqa wokukhiqiza wamukela uhlelo lokulawula oluthuthukisiwe ukuze kuqinisekiswe ukusebenza okunembile nokuzinzile komugqa wokukhiqiza. Itheminali yokusebenza eshumekiwe ingaqedela ukulungiselelwa kwepharamitha ngokushesha nakalula.

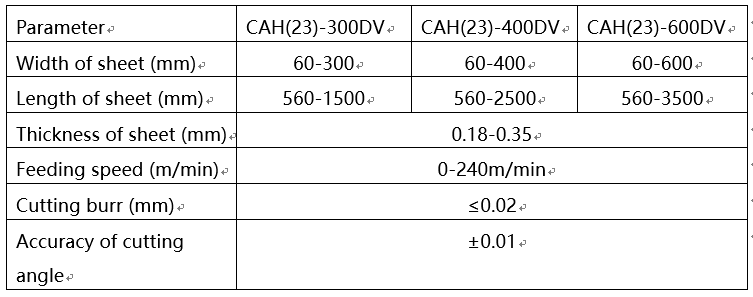

| Ipharamitha | I-CAH(23)-300DV | I-CAH(23)-400DV | I-CAH(23)-600DV |

| Ububanzi beshidi (mm) | 60-300 | 60-400 | 60-600 |

| Ubude beshidi (mm) | 560-1500 | 560-2500 | 560-3500 |

| Ubukhulu beshidi (mm) | 0.18-0.35 | ||

| Isivinini sokudla (m/min) | 0-240m/min | ||

| I-burr yokusika (mm) | ≤0.02 | ||

| Ukunemba kwe-engeli yokusika | ±0.01 | ||

Ulwazi Lomkhiqizo

Umugqa wokusika ube ngobude uklanyelwe ukukhiqizwa kwensimbi yeshidi ngokulinganisa nokusika ikhoyili kamama ibe izingxenye eziphambanayo, kwakhiwe amafomethi ayisicaba anamathiselwe kahle. Inqubo eyisisekelo yemigqa yokusikwa iye kobude ihlanganisa ukuhlehlisa, ukubeka izinga, ukusika, ukupakisha nokupakisha.

Imigqa yokusikwa kwensimbi ibe ngobude isetshenziselwa ukucubungula izinsimbi zibe izingcezu zobude obunembile ukuze kuqhutshekwe nokucubungula noma ngezinjongo zokuthengisa kabusha. Ulayini ojwayelekile wokusika uye kubude uhlanganisa inombolo yemishini ukuze unikeze izinsizakalo ezingeziwe ngenkathi ucubungula ikhoyili ibe yisiqephu.

Izinzuzo zomugqa wokusika ube nobude:

Umugqa wokusika uye kubude ungenza ukondla futhi usebenzise idrayivu ye-AC servo.

Ulayini osikiwe uye kubude unendawo eqinile ene-chrome plated futhi iqinile futhi imelana nemihuzuko.

Umugqa wokusika uye kubude unohlelo lokulawula ubude bedijithali ngokugcwele oluqinisekisa ukuma okusheshayo ngephutha elincane.

Njengabahlinzeki bezinto zikagesi abanolwazi lweminyaka eminingi, sinikezela ngezinsizakalo zokuvuselela ezichwepheshile nokufaka ngokugxila kwangempela ekwanelisekeni kwamakhasimende. Sinemiphumela eqinisekisiwe yokubeka izindinganiso ezihlukile ekulawuleni izindleko, ukuhlela, ukuhlela nokuphepha kwephrojekthi. Sinokuhlangenwe nakho okusinika ithuba lokuncintisana ngaphezu kwabanye abasensimini yethu.

Ukucaciswa kobuchwepheshe

Ukusebenza

1.Ukuqaqa amakhanda amabili

Ububanzi bangaphakathi bekhoyili: 495-510mm

Ikhoyili ephezulu ububanzi bangaphandle: 1200mm

Umthwalo omkhulu ngekhanda ngalinye: 2tons

Isivinini sokuqaqa: lungisa ngokuhambisana nokudla

I-uncoiler isebenzisa ukulawulwa kwesivinini esingenasinyathelo esivumelanayo ukulandela ukuphuma, ukungezwani kwe-hydraulic, i-disc brake kanye nokujikeleza kukagesi.

2. Isiphakeli sangaphambili nangemuva

Isiphakeli sangaphambili nangemuva sakhiwe ngerola ephakelayo ephezulu naphansi kanye nerola yokulinganisa, idrayivu yokondla isebenzisa uhlelo lokulawula ukunyakaza lwe-German Siemens Simotion. Lo mshini wamukela umklamo osezingeni eliphezulu kakhulu wokumisa isikhungo se-servo push and pull material mechanism; i-roller yokudla yenziwe ngezinto ze-polyurethane, ubude bokulinganisa i-encoder kanye nokulawula i-servo i-loop evaliwe, isivinini sokudla esivamile singu-0-180 m/min, isivinini sokuphakela esiphezulu singu-240 m/min. I-feeder yangaphambili iqhuba indima yezinto eziphushayo, futhi i-feed yangemuva iqhuba indima yezinto ezidonsayo. Okuphakelayo okubili kungasebenza ngokuvumelana ukuze kugcinwe okubalulekile esiteshini kuqondile.

3. O Punch Futhi Two V-Notch

Lo mshini unamasethi amabili we-O-Punch ne-V-Punch, isethi eyodwa ye-O-Punch, iqhutshwa yi-servo motor ingakwazi ukubona isinyathelo sokunyakaza kwe-lateral, amasethi amabili we-V Notch ubuso nobuso afakwe ezinhlangothini zombili ze-O Punch, eqhutshwa yi-servo motor angakwazi ukubona ukunyakaza kwesinyathelo sobude;

Idizayini ingasika ijoka kanye nomphetho ngokwehlukana, okonga izinto zamakhasimende.

4. Ingxenye yokugunda

Amasethi amabili ezingxenye ze-shear afakwe epuleti elilungisiwe kuma-degree angu-45 kanye nama-degree angu-135, Ipuleti elilungisiwe lifakwe ku-sliding block of the movable parallel guide rail, futhi ipuleti elingaguquki lingakwazi ukuhamba ngokuvundlile ngokusebenzisa i-servo motor drive;

Isigaba sokugunda sihlanganisa: +45° amashekeli namashekeli angu-135°, ithebula lama-slide eliphambanayo kanye ne-roller yokukhipha. Isakhiwo samaqembu amabili emishini yokugunda senziwe ngokusakazwa. Ukugunda kushayelwa yi-Siemens servo motor esebenza kahle kakhulu nomsindo ophansi.

Ithuluzi (die) lamukela ithuluzi eliqinile lokusika i-alloy, isikhathi sokugaya ngasinye sisebenzisa izikhathi ezingaphezu kwesigidi esingu-1. Ngomshini wokulungisa ukujula, ukuze ithuluzi likwazi ukulungiswa ngemva kokugqoka.

5. Idivayisi yokulungisa ububanzi obumaphakathi:

Wonke umugqa wokusika uye kubude usebenzisa ukuma okumaphakathi kanye nokulungiswa kobubanzi obumaphakathi ukuze uvumelane nobubanzi obuhlukene bokudluliswa kwempahla yeshidi.

Impendulo yendawo yesifaki khodi nesibonisi sendawo yesikhombi. Indlela yokulungisa ububanzi isebenzisa i-ball screw drive ukuze kuzuzwe ukuxhumana okulungisa ububanzi obumaphakathi kwawo wonke umugqa. Idivayisi yokulungisa ububanzi nayo ifakwe i-alamu evimbelayo ukuze ibone ukumiswa kwawo wonke umshini lapho impahla i-arched.

6. Indlela yokukhipha kanye nokunqwabelanisa

Ishayelwa ibhande le-Siemens servo motor magnetic conveyor, idivayisi idlulisa ishidi eligundiwe lisuka kusikekelo liye kumshini wokuhlela wezingqimba ezimbili.

Imishini ihlukaniswe yaba izingqimba ezimbili zezinto ezibonakalayo, ungqimba ngalunye luqhutshwa yi-Siemens servo motor magnetic conveyor belt ukuma okunembile ngemva kokuwela kuphini lokubeka elimisiwe, ukuwa okuzenzakalelayo ku-trolley, kunganqwabelanisa amakholomu angu-2-4.

CONTACT E-US

.

.

SHIYA UMLAYEZO

Sicela ugcwalise futhi uthumele ifomu elingezansi, sizokuthinta emahoreni angama-48, ngiyabonga!

REKUNCONYWA

Wonke akhiqizwa ngokuvumelana nezindinganiso zamazwe ngamazwe eziqinile. Imikhiqizo yethu ithole umusa kuzo zombili izimakethe zasekhaya nezangaphandle.