Abakhiqizi Benziwe Ngokwezifiso Irobhothi Le-AI Elihlakaniphile Lifinyelele Ubude Abakhiqizi Abasuka kubakhiqizi baseChina-CANWIN

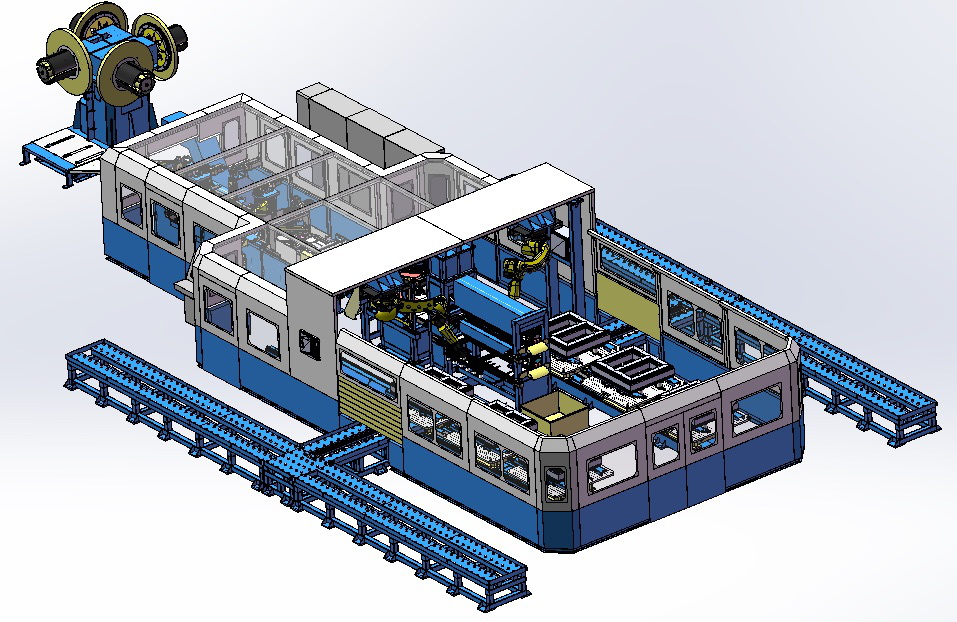

Isikhungo sokucutshungulwa kwensimbi ye-CANWIN sakhiwe ngohlelo lokulawula ukunyakaza lwe-Siemens kanye ne-servo motor, umshini wokugcwalisa amarobhothi amabili amisiwe, isiteji sokushintshana se-servo eziteshini eziyisithupha, kanye nesiteshi sezinto ezimbili. Ihlanganiswe nomugqa wokusika we-Keying 1250 wohlobo lwe-spacer onesivinini esikhulu, isistimu ye-MES ehlakaniphile ye-warehouse ixhuma ngaphandle komthungo nesikhungo sokucubungula i-iron core. Ixazulule ngempumelelo izinkinga zokusika kuphela nokungapakishi imigqa yokusika evundlile esikhathini esidlule, edinga ukuphathwa okuphindaphindiwe ngezimoto ezidluliswayo, ukubekwa kwangaphambi kwezinkinga ze-truss mechanical laminations, ukusebenza kahle okuphansi, ukusebenza komhlaba okukhulu, kanye nesidingo sabasebenzi! Ifaneleka ngokukhethekile ukukhiqizwa okujwayelekile kwamabhizinisi amakhulu embonini yamandla yesikhathi esizayo (enomphumela omkhulu wonyaka ).

Ukusetshenziswa komshini wokupakisha we-transformer lamination

Njengomunye wabakhiqizi abachwephesha be-transformer lamination e-China, iCanwin igxile ekukhiqizeni i-transformer lamination iminyaka engaphezu kwengu-20. umshini wokupakisha we-transformer lamination ikhethekile ekwenzeni i-transformer lamination.

1. Izindleko eziphansi, zingasetshenzwa ngumuntu oyedwa.

2. Ihlangene, indawo engamamitha ayi-12 x 24 kuphela edingekayo.

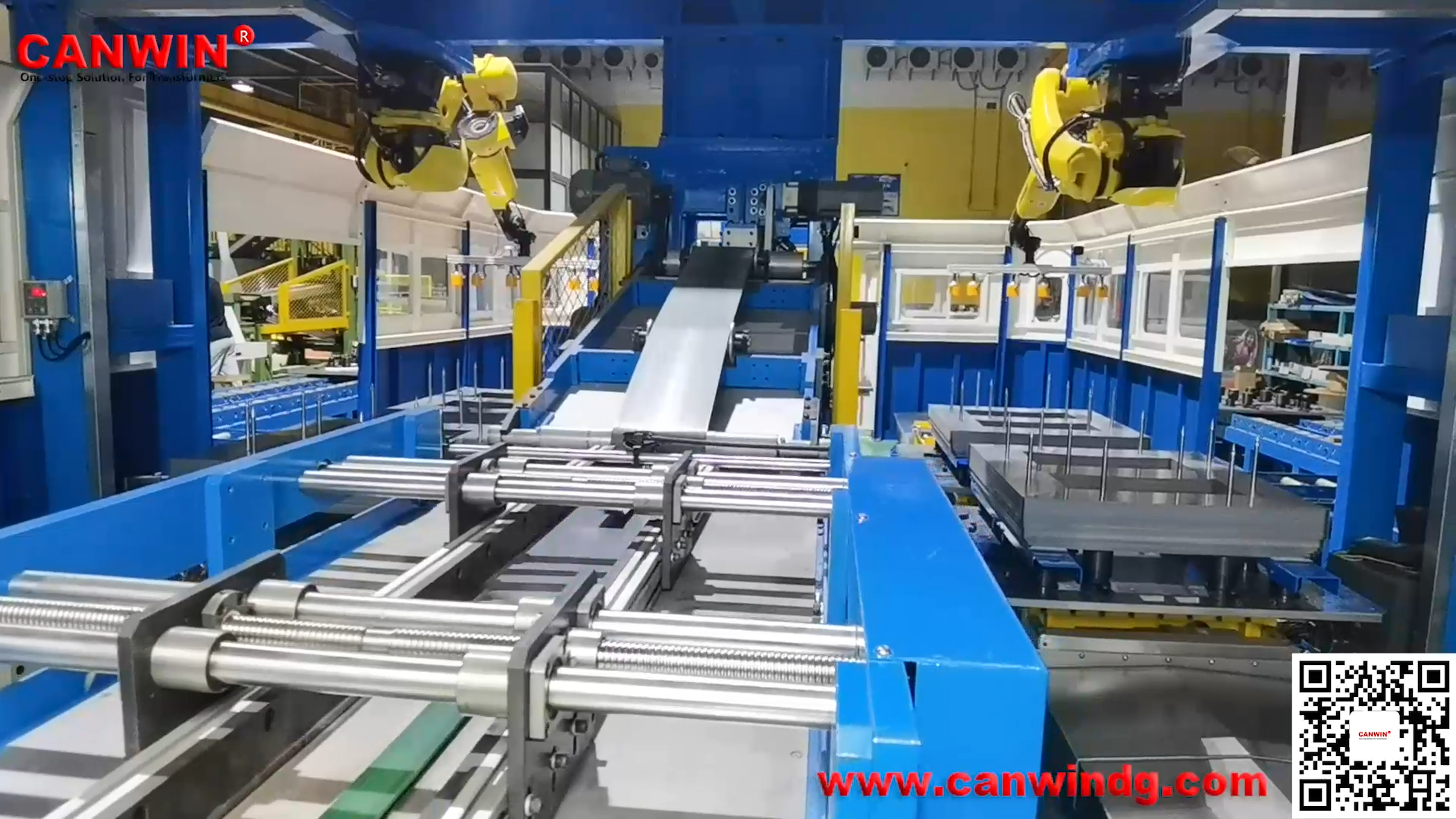

3. Ukusebenza kahle okuphezulu, ukubamba izingcezu eziyi-7 ngesikhathi esisodwa, amarobhothi amabili angakwazi ukubamba izingcezu eziyi-14 ngesikhathi esisodwa.

4. Ukulahleka kwempahla ephansi, asikho isidingo somsebenzi osindayo wokubamba ngesandla, kanye nomonakalo omncane kumashidi ensimbi ye-silicon.

5. Izinga eliphezulu lokusebenzisa impahla, akukho mfucuza eyeqile, kanye ne-automemboziwe ngemuva kokusika.

6. Ubuchwepheshe bokucubungula obusezingeni eliphezulu kanye nemishini yemboni engu-4.0 yangempela.

7.Umzimba womshini ushiselwe ngensimbi yekhwalithi ephezulu kanye ne-casting punching kanye nengxenye yokugunda. Indawo yokufaka yenziwe ngepuleti lensimbi elijiyile. Isakhiwo siqinile futhi siqinile, futhi inkathazo efihliwe ye-deformation iqedwa ukwelashwa kokushisa.

8. Umshini wokubhoboza nokugunda wenziwa ikakhulukazi ngezinga eliphezulu, okungasoze kwakhutshazwa, okusiza ekuqinisekiseni ukunemba kokugunda nokwenza ngcono impilo yesevisi yethuluzi; Ngesikhathi esifanayo qeda ngempumelelo ingxoxo ye-shear nomsindo.

9. Uhlelo lokuphakelayo oluthuthukisiwe, ukusebenza okuzinzile nokuthembekile, ukuqinisekisa ukuthi ishidi lensimbi ye-silicon lingalethwa ngesivinini esikhulu.

10. I-punch and shearing mechanism iqhutshwa injini ye-servo ephendulayo ephezulu, enembile futhi ephumelelayo.

11. I-punching ne-shear yenziwe nge-alloy eqinile yekhwalithi ephezulu, enempilo ende yesevisi kanye nokugqoka okuncane.

12. Isistimu yokulawula kagesi ye-Siemens yamukelwa ukuze ibone ukuzimisela okunembile kokugunda okude, ukulawulwa kwe-loop okuvaliwe okugcwele, ukutholwa kwe-inthanethi kanye nokulungiswa kwenhlawulo okuzenzakalelayo.

13. Indlela yokulungisa ububanzi iqhutshwa yi-servo motor futhi ilawulwa yikhompyutha ukuze ibone ukulungiswa kobubanzi okuzenzakalelayo.

Main nemingcele lobuchwepheshe of theumugqa wokukhiqiza wesika uye ubude:

1. Ibanga lokucubungula:

Ubukhulu: 0.18-0.35 mm

Ububanzi beshidi: 80-440mm (ishidi elijwayelekile)

80-400mm (isinyathelo sokugunda)

Ubude: 400-1500 mm

2. Izidingo zekhoyili ezisetshenziswe kulo mugqa wokukhiqiza wokusika ukuya kubude:

Ukubekezelela ububanzi :±0.1mm

Amabhula: 0.02 mm noma ngaphansi

Ukuchezuka kwe-S-degree: ≤0.2mm ohlangothini olulodwa phakathi kuka-2000mm

Ukuphaphazela kwempahla: ukuphakama kwegagasi lendawo ≤1mm

Okubalulekile akukwazi ukuba nendawo yokugqwala, ukuchezuka kogqinsi ≤0.02mm

3. Ukunemba kwalokhu kusikwa kwesivinini esikhulu ukuya kumugqa wokukhiqiza ubude:

Ukubekezelela ubude: ± 0.2mm;

Ukubekezelela i-engeli :±0.025°

Amabhula: 0.02 mm noma ngaphansi

4. Isivinini sokudla: isivinini sokudla esisebenzayo 150m/min

5. Impilo yamathuluzi: abasiki abavundlile izikhathi ezingekho ngaphansi kwesigidi esingu-1 (i-blade eyodwa igaya kanye);

Izinto ze-carbide ezinosimende

I-V Cutters izikhathi ezingekho ngaphansi kuka-800,000 (i-blade eyodwa igaya kanye);

Izinto ze-carbide ezinosimende

O Abasiki izikhathi ezingekho ngaphansi kuka-500,000 zamathuluzi okubhoboza(i-blade eyodwa igaya kanye).

Izinto ze-carbide ezinosimende

6. Isamba somthamo wokufaka: cishe 40Kw

7. Ingqikithi yokusetshenziswa komoya :0.2 m3 / min

8. Izimo zokusebenza:

(1) Izinga lokushisa alikho ngaphezu kuka-40°C;

(2) Ukushintshashintsha kwamandla kagesi 380V±10%;

(3) imvamisa 50 hz

9. Ngomsebenzi wokunyathela we-longitudinal

11. Isiqondiso sokusebenza: umugqa wesokudla (ubhekene nemishini ukusuka ohlangothini lwesiteshi esikhulu sokulawula, isiqondiso sokuphakela ukusuka kwesobunxele kuya kwesokudla).

12.Uhlobo lwengxenye yokugunda: igxathu lesi-5 longitudinal, isinyathelo esingu-7 ubude;

Igama lenombolo yomkhiqizo umkhiqizi wobuningi noma izwe

Isilawuli se-Ac servo 20 Siemens, Germany

Ikhoyili ububanzi bangaphakathi: 500mm

Ikhoyili ephezulu ububanzi bangaphandle: 1200mm

Umthwalo omkhulu ngekhanda ngalinye: amathani ama-2

Isivinini sokuqaqa: lungisa ngokuhambisana nokudla

I-uncoiler isebenzisa ukulawulwa kwesivinini esingenasinyathelo esivumelanayo ukulandela ukuphuma, ukungezwani kwe-hydraulic, i-disc brake kanye nokujikeleza kukagesi. Ngetafula lesilayidi elizenzakalelayo, ikhanda lokuphakela lingafakwa imiqulu eminingi yezinto; I-uncoiler ifakwe endaweni egudlukayo futhi imbobo yokuphakelayo ifakwe indawo yokukhanya okubomvu ukuze kuqinisekiswe ukuthi okokusebenza kumaphakathi nesiteshi sokuphakelayo.

Idivayisi ye-2.Guide buffer

Ayikho imodi yebhafa yomhlahlandlela womgodi (uhlobo lomgodi), enesistimu yokuqaqa, indawo ebomvu nezinye izingxenye.

Sisebenzisa ubuchwepheshe bemodeli yensiza enelungelo lobunikazi benkampani yethu,

Isigaba se-punch samukela i-Ductile casting in batch , futhi samukela isikhungo semishini ye-axis emihlanu ukuze sicutshungulwe kanye nokwenza ngemva kokuqeda ingcindezi. Isitimela somugqa wesikwele esingenisiwe; I-Servo motor drive ye-O punching nokugunda, ukusebenza kahle okuphezulu, umsindo ophansi. Ithuluzi (die) lamukela ithuluzi eliqinile lokusika i-alloy, isikhathi ngasinye sokugaya sisebenzisa izikhathi ezingekho ngaphansi kuka-500,000.

Isigaba se-V Notch: kusetshenziswa ubuchwepheshe belungelo lobunikazi bemodeli yenkampani yethu,

yamukela isikhungo semishini esinama-axis amahlanu ukuze sicutshungulwe kanye kanye nokwenza ngemva kokuqeda ingcindezi. Yamukela umugqa oyisikwele ongenisiwe

Umzila wesitimela; Ibanga lokubhoboza: ± 50mm phakathi nendawo yeshidi, i-V Notch isebenzisa i-servo motor drive, ukusebenza kahle okuphezulu, umsindo ophansi. Ithuluzi (die) lamukela ithuluzi eliqinile lokusika i-alloy, isikhathi ngasinye sokugaya sebenzisa izikhathi ezingekho ngaphansi kwesigidi esingu-1.

I-Longitudinal V-notch ihanjiswe yi-servo motor.

Sisebenzisa ubuchwepheshe bemodeli yensiza enelungelo lobunikazi benkampani yethu,

Ingxenye yokusika isebenzisa i-Ductile casting in batch, futhi yamukela isikhungo semishini esinezinhlangothi ezinhlanu ukuze sicutshungulwe kanye

kanye nokwenza ngemva kokuqeda ingcindezi. Ngaphezu kwalokho, sisebenzisa isitimela somugqa wesikwele Esingenisiwe.

Isigaba se-Cutter sihlanganisa: +45 ° shears, -45 ° shears, ithebula lama-slide eliphambene, i-discharge roller nokunye.

Abasiki bamukela i-servo motor drive, esebenza kahle kakhulu, umsindo ophansi.

Ithuluzi (die) lamukela ithuluzi eliqinile lokusika i-alloy, isikhathi ngasinye sokugaya singasebenzisa izikhathi ezingaphansi kwesigidi esingu-1.

Isigaba sokusika ngokuqina kwe-welding yeshubhu elingunxande, itafula lokusika ngo-50 mm ubukhulu bepuleti lokushisela, ngemuva kokuqeda ukucindezelwa kusetshenziswa isikhungo esikhulu somshini we-gantry ukwakheka kwe-clamping, ukubhola kwephaneli yangaphambili, Ukuthepha, i-chamfering, indiza, i-slotting, njll. isikhungo, ukuqinisekisa ukuthi isikhundla isihlobo ngasinye imbobo indawo futhi liqondise ukufakwa olunembile kakhulu! Lo mshini uklanywe ngokukhethekile ngolayini we-datum wocingo omaphakathi onokuzihlola , kulula ukuyifaka futhi ulungise futhi ulungise idatha yethrekhi yokuphakelayo.

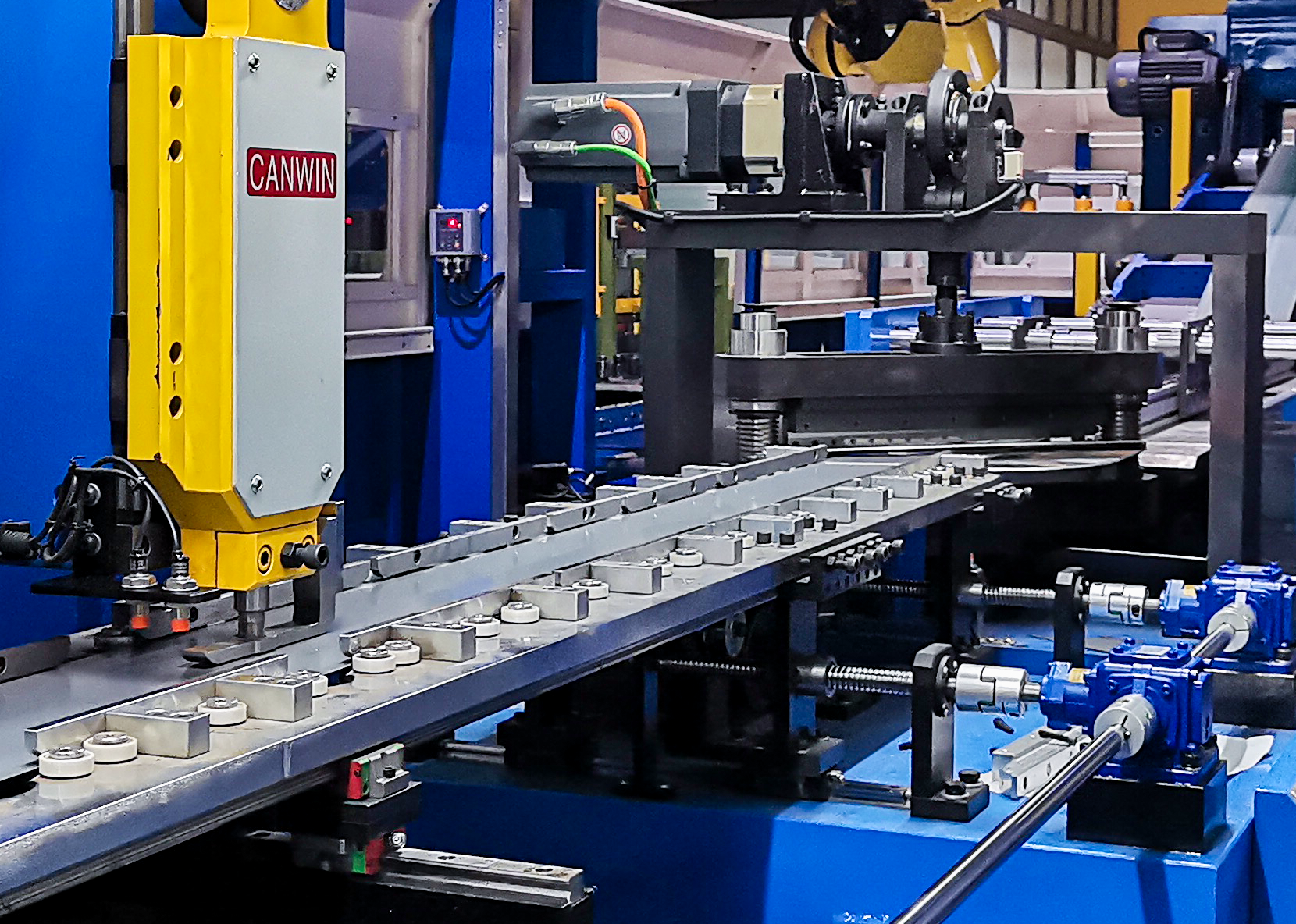

Ithrekhi ithatha umklamo ovulekile, owakhiwa ipuleti eliyisisekelo, ujantshi kanye ne-ceramic bearing, ujantshi oqondisayo ulungele ukuhlanza, ukushintshwa okuthwalayo kulula kakhulu;

Ingxenye yendawo engezansi nengaphezulu yesiteshi inikezwa idivayisi yomkhawulo, into esuka phakathi nendawo yendawo phakathi nendawo, ukuvimbela ukushaywa kwezinto;

I-servo motor yendlela yokulungisa ububanzi ishayelwa isikulufu sebhola ukuze kufinyelelwe ukuxhunyaniswa kokulungiswa kobubanzi obumaphakathi kwawo wonke umugqa wokukhiqiza osikiwe uye kubude.

Idivayisi yokulungisa ububanzi nayo ifakwe i-alamu evimbayo ukuze ibone ukumiswa kwayo yonke insimbi ye-silicon.i-transformer lamination umshini wokupakisha lapho impahla i-arched.

Isikhungo somshini samukela i-Guangdong Canwin invention patent [CN03990731A] ubuchwepheshe bokusunduza nokudonsa kanye nobuchwepheshe bokugunda umsila, ukuxazulula ngempumelelo ukuphakelwa kwempahla ngesivinini esingu-0.18mm kwenkinga yokuxhuma nokushear ngokunemba, kuyilapho kuthuthukisa kakhulu izinga lokusebenzisa impahla.

Umshini wokuphakela umsila kanye nesilawuli se-micro tension kufakwe kuma-parallel guide rails, angashintshwa ngokuzenzakalelayo ngezinhloso ezahlukene; Lapho umshini wokusonga usuqediwe, okokusebenza kuzoyeka ukusebenza ngokuzenzakalelayo, ngalesi sikhathi isondo lokucindezela le-micro-tension mechanism liyaphakanyiswa, futhi isondo lokuphakela umsila lishintshelwa ku-clamping impahla ephezulu nge-shift cylinder, bese uqhubeke ukusika impahla yomsila; Ubude be-shear yomsila bungasethwa, i-roller yokudla ephansi iyinduku yensimbi enembile ene-encoder.

8.Ipulatifomu yokukhipha

Ukuma phakathi nendawo, ingxubevange ehlanganisiwe yomhlahlandlela, impilo ende yesevisi, ukuguga- ukumelana& isikhathi eside! I-motor yokukhipha ilawulwa yi-Siemens servo motor.

Ingaphezulu nangaphansi kwe-servo motor ingaqedelwa ukuhlunga okunembile, ukupakisha izingcezu ezi-5 noma eziyi-7 ngesikhathi; Isiteji sokuphakela sithatha i-Siemens servo motor ukuze ibone ukushintshana okuzenzakalelayo, okungahlangabezana nezidingo zezingcezu ezingu-5/7 ezikhishwe irobhothi ngesikhathi.

Inaliti yokubeka ifakwe ku-platform ye-laminating ezenzakalelayo, futhi i-transformer core ifakwe endaweni yesikhulumi se-laminating ukuze ihlangabezane nezidingo ze-laminating; Isikhungo somshini sinezinkundla eziyisithupha zokupakisha, ezifakwe kuma-sliding rails alawulwa ama-servo motors agudlukayo futhi angashintshwa ngokuzenzakalelayo;

12. Ishaneli yokuphumayo eyinhloko

Ingqikithi estakiwe ingadluliselwa ngokushesha esiteshini ngalo mshini, bese kulandela ukucubungula komsebenzi; Isikhungo sokucubungula singaqhubeka nokusebenza, ngeke sibe nomthelela ekukhiqizeni okuvamile.

12. Ishaneli yokuphumayo eyinhloko

Ingqikithi estakiwe ingadluliselwa ngokushesha esiteshini ngalo mshini, bese kulandela ukucubungula komsebenzi; Isikhungo sokucubungula singaqhubeka nokusebenza, ngeke sibe nomthelela ekukhiqizeni okuvamile.

12. Ishaneli yokuphumayo eyinhloko

Ingqikithi estakiwe ingadluliselwa ngokushesha esiteshini ngalo mshini, bese kulandela ukucubungula komsebenzi; Isikhungo sokucubungula singaqhubeka nokusebenza, ngeke sibe nomthelela ekukhiqizeni okuvamile.

13. Uhlelo lokulawula ugesi

Wonke umugqa usebenzisa isilawuli sokunyakaza se-Siemens simotionD435, i-S110 series servo motor, BUS ukulawula. Nge-interface yesistimu yokuphatha ye-MES, elula kakhulu ukuqoqa idatha yokukhiqiza ohlelweni lokuphatha yesikhulumi sokukhiqiza, futhi uqaphele ukukhiqizwa nokuqapha okuhlakaniphile;

Izingxenye eziyisipele ezijwayelekile:

1. I-photoelectric switch kanye ne-proximity switch yawo wonke umshini ingu-1:1 njengezingxenye ezisele.

2. I-punching die kanye ne-V notch, izikele ezivundlile zifakwe ngokuka-1:1.

FAQ

1.Yini esingakwenzela yona?

Singakuhlinzeka ngezinto zokwakha zesiguquli samandla kanye nezinsizakalo zobuchwepheshe ukuze udale ifekthri eqinile encintisanayo yesiguquli. Singakunikeza ngezinsizakalo ezikhethekile ze-OEM/ODM ze-transformer. Ngisho noma ungenalo ikhono lokukhiqiza, ungaphinde uhambe uyolanda i-oda lakho. Singakunikeza zonke izinto zokusetshenziswa zekhwalithi ephezulu ozidingayo ukuze ukhiqize isitshalo sakho se-transformer. Yiqiniso, intengo kumele ibe ekhangayo kakhulu!

2.Iminyaka emingaki inkampani yakho yenza lolu hlobo lwemishini?

Sineminyaka engu-20 yesipiliyoni sokumaketha kanye nesikhungo sokukhiqiza sesimanje esingamamitha-skwele angama-200,000.

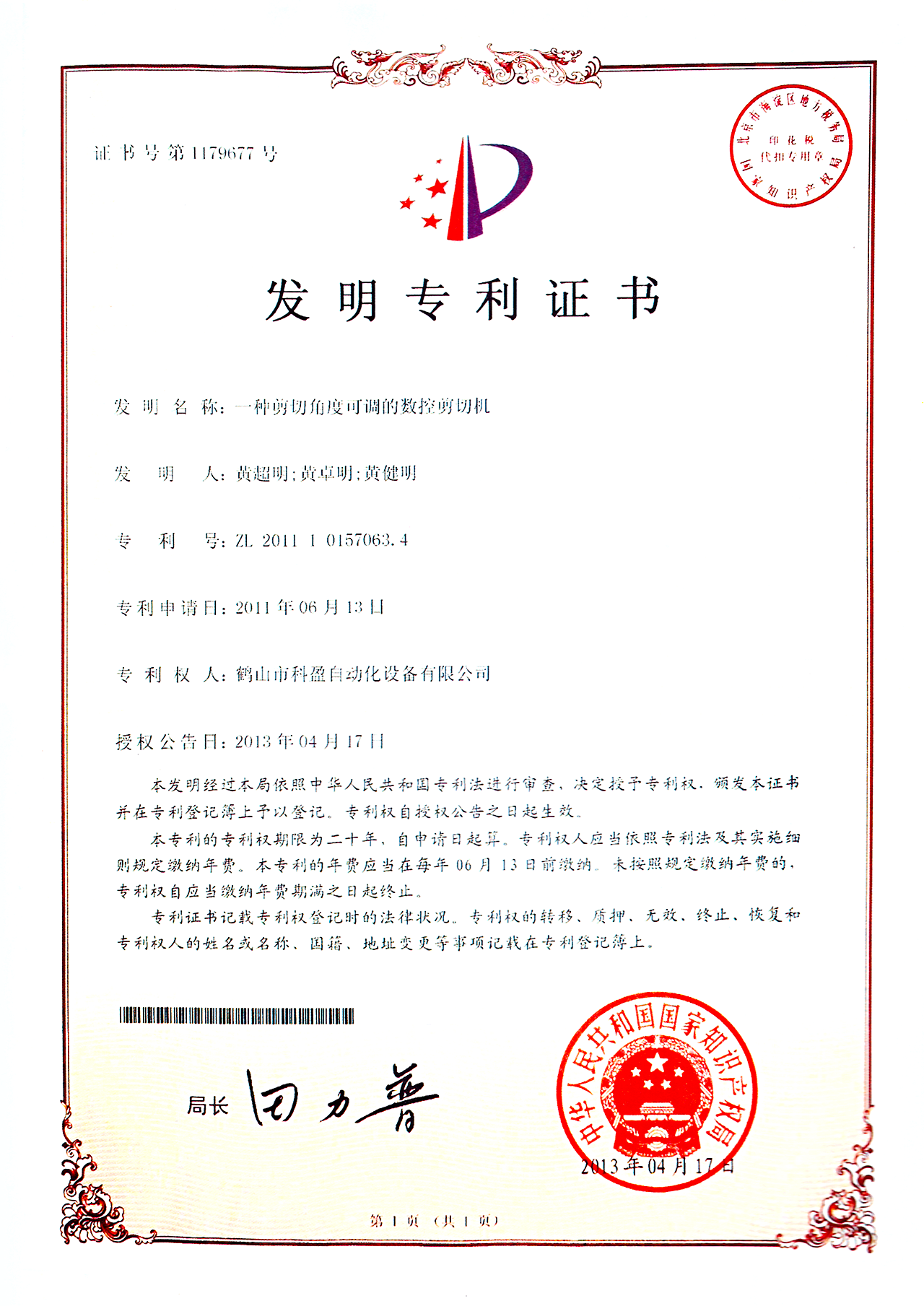

3.Isiphi isitifiketi onaso semishini yakho?

Sinamalungelo obunikazi angama-56 emikhakheni yokusungulwa kwamazwe ngamazwe. ISO9001 / SO14001/ STL / ASTA / KEMA

4.Ungathumela abasebenzi bakho ukuthi basifakele imishini?

Ngemuva - ukuthengisa kumahhala ukuhlinzeka ngonjiniyela ngokufaka endaweni kanye nokulungisa iphutha kanye nokuqeqeshwa kobuchwepheshe obuchwepheshile.Phendula imibuzo yakho yobuchwepheshe noma yobuchwepheshe ngocingo noma ngokubhala.

5.Ingabe unayo i-ejenti ezweni lakithi?

I-CANWIN iguqule futhi ithuthukise izimboni zendabuko njengethuba lokujulisa ukwakheka kwesu "ibhande elilodwa nomgwaqo owodwa", kujulise ukubambisana nezimakethe zangaphandle. ngendlela yokubambisana kanye nenzuzo efanayo, yamisa isikhungo sokukhiqiza i-transformer kanye nesisekelo sokucubungula okuyisisekelo eMpumalanga Ephakathi, eNdiya. I-Dubai. Vietnam. Thailand. njll.Esikhathini esizayo, i-CANWIN izoqhubekela phambili ekuqondisweni komholi wemishini ehlakaniphile, okwenza i-China ibe nedumela lomhlaba wonke!

CONTACT E-US

.

.

SHIYA UMLAYEZO

Sicela ugcwalise futhi uthumele ifomu elingezansi, sizokuthinta emahoreni angama-48, ngiyabonga!

REKUNCONYWA

Wonke akhiqizwa ngokuvumelana nezindinganiso zamazwe ngamazwe eziqinile. Imikhiqizo yethu ithole umusa kuzo zombili izimakethe zasekhaya nezangaphandle.