1. Classification and models of power transformers

2. 1. Classification by use

3. (1) Step-up transformer: used by the power plant to transmit electricity to the outside.

4. (2) Step-down transformer: The substation of the power supply bureau is used for voltage conversion.

5. (3) Distribution transformer: used to supply power to users.

6. (4) Plant transformer: Provides internal electricity for the power plant.

7. (5) Transformer for station: Provide internal electricity for the substation.

8. (6) Converter transformer: for DC power transmission, one side is connected to AC power, and one side is connected to the converter valve.

9. (7) Rectifier transformer: used in thermal power plants to supply power to electrostatic precipitators.

1. 2. Classification by winding

2. (1) Double-winding transformer: used for step-up transformer, step-down transformer, factory transformer, etc.

3. (2) Three-winding transformer: used for step-down transformer, tie transformer, etc.

4. (3) Self-coupling transformer: used for step-down transformer, liaison transformer, etc.

5. (4) Split transformer: There are two types of axial split and radial split, which are used for factory transformers and start-up transformers.

7. 3. Classification by structure

8. (1) Single-phase transformer: used for 330~1000kV transformers.

9. (2) Three-phase transformer: used for 10~500 kV transformer.

10. (3) Combined transformer: The transformer is divided into several parts, and the transformer is combined after arriving at the site, which is used in areas with inconvenient traffic.

12. 4. Classification by cooling method

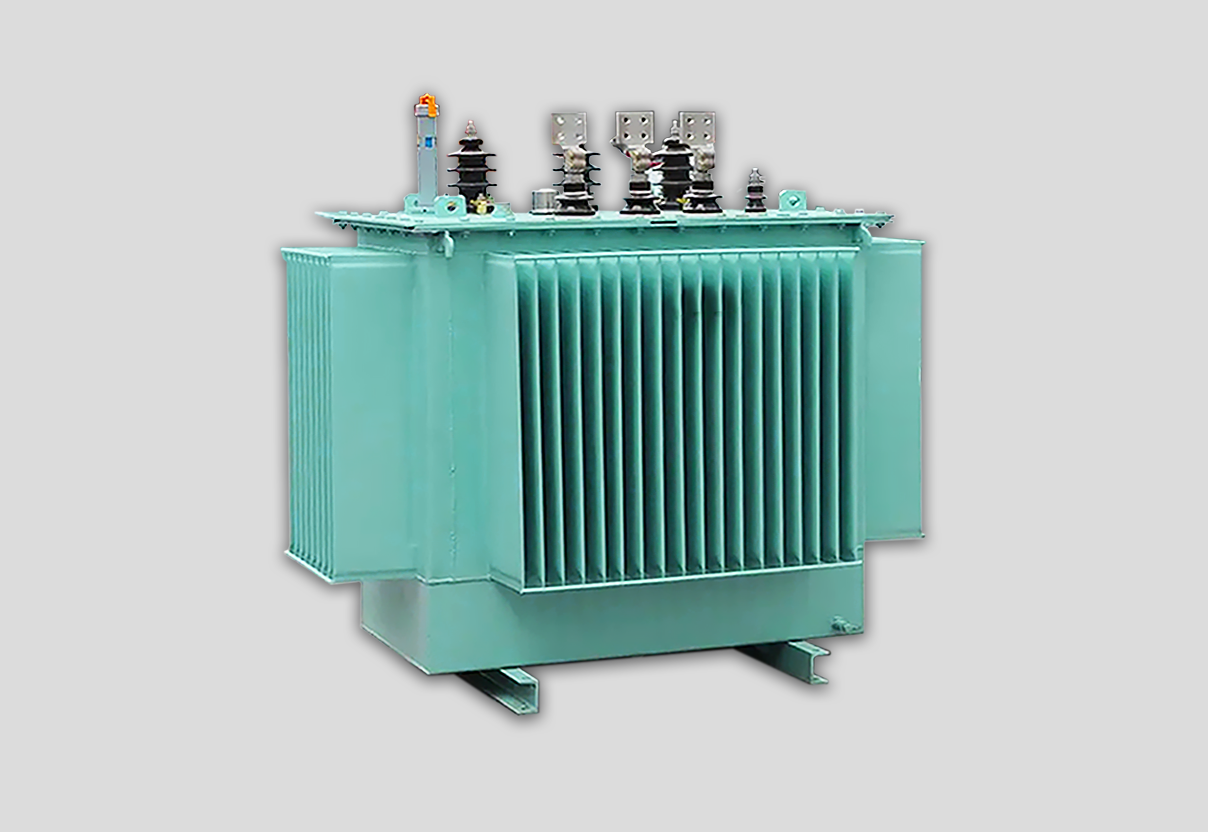

13. (1) Oil-immersed transformer: used for 10~1000kV transformers.

14. (2) Dry-type transformer: used for 10~110 kV transformers.

15. (3) SF6 transformer: currently used for 110 kV transformers.

17. 5. Model of power transformer

19. (1) The meaning of the letters in the model

21. D—Single phase F—Oil immersion air cooling

22. O—self P—forced oil circulation

23. S—Three-phase or three-coil J—Oil-immersed self-cooling

24. Z—On-load voltage regulator L—Aluminum coil

26. * Copper coils and double coils do not need to add symbols

28. (2) Example

30. SFPSL—120000/110: 110kV, 120MVA three-phase three-coil forced oil circulation air-cooled aluminum coil transformer

32. OSFPSZ—240000/330: 330 kV, 240MVA three-phase three-coil on-load voltage regulation forced oil circulation air-cooled self-coupling transformer

Second, the coil of the power transformer

The coil is the most important and complex part in the power transformer. It is made of copper (or aluminum) wire and is composed of special insulating parts.

1. Spiral coil

The main feature of the spiral coil is that the number of parallel wires is large, the wire cake is wound into a spiral, and one wire cake is a coil of one turn. The spiral coil has good mechanical stability, good heat dissipation and good craftsmanship, and is widely used in low-voltage and high-current coils of transformers.

The helical coil can be wound into three structures of single helix, double helix and quadruple helix according to the size of the current.

2. Continuous coil

When the coil is composed of several wire segments distributed along the axial direction and do not need to be welded to each other, it is called a continuous coil.

The end support surface of the continuous coil is large, the axial force is large, the short-circuit resistance is strong, and each line segment has a large heat dissipation capacity. This kind of coil has a wide range of applications regardless of voltage level or capacity range.

3. Tangled coil

A tangled coil consists of several tangled line segments (pies). Coils with all tangled line segments (cakes) are called fully tangled coils, and are widely used in transformers with voltages of 220kV and above. A coil composed of a part of the tangled line segment (cake) and a part of the continuous line segment is called a tangled continuous coil, which is applied to transformers with voltages of 66 kV and above.

Since it inserts non-adjacent turns between adjacent turns of the coil, staggered tangled line segments are formed and a tangled coil is formed, thereby increasing the longitudinal capacitance of the coil and making the impulse voltage along the axial height of the coil. The distribution characteristics are improved, so it is widely used in various high-voltage coils.

4. Inner shielded coil

The inner shield continuous coil is to improve the impulse voltage distribution by increasing the series capacitance between the line segments. Its structural feature is that the additional capacitor turns are directly wound inside the continuous line segment. The ends of the capacitor turns are wrapped in insulation and then suspended in the line segment. The capacitor turns do not carry current and only work under impulse voltage.

Internally shielded continuous coils are structurally available in the form of two-section jumper, four-section jumper, eight-section jumper and segmental connection.

Third, the iron core of the power transformer

The iron core is also an important component of the power transformer. It is formed by stacking high-permeability silicon steel sheets and then clamping them with steel clips or tying them with glass ribbons.

1. Silicon steel sheet

The silicon steel sheets used in power transformers are cold gadolinium silicon steel sheets with a thickness of 0.3~0.5mm. At present, only Wuhan Iron and Steel Plant and Shanghai Baosteel can produce such cold gadolinium silicon steel sheets. However, silicon steel sheets for large transformers have to be imported from Japan.

2. The structure of the iron core

(1) Single-phase two-column iron core, used for various single-phase transformers.

(2) Single-phase section column side yoke core, used for high-voltage large-capacity single-phase transformers.

(3) Single-phase two-column side yoke core is used for high-voltage and ultra-high-voltage large-capacity single-phase transformers.

(4) The three-phase three-column is the iron core, which is used for various three-phase transformers.

(5) Five-column iron core for large-capacity three-phase transformers.

Fourth, the oil tank of the oil-immersed transformer

1. The barrel type oil tank is mainly used for various small oil-immersed transformers and extra-large oil-immersed transformers.

2. Bell jar type oil tank, widely used in 110~500kV oil-immersed transformer.

3. The fully sealed oil tank is about to be welded to death. It has only been used in oil-immersed transformers of 110kV and above in recent years.

5. Oil conservator of oil-immersed transformer

The oil conservator of the transformer has two functions, one is to provide space for thermal expansion and contraction of the transformer oil in the oil tank; the other is to isolate the transformer oil from the external atmosphere to prevent the transformer oil from aging.

1. Capsule-type oil conservator, which uses rubber capsules to separate the transformer oil from the external atmosphere, and provides space for thermal expansion and contraction of the transformer oil.

2. Diaphragm oil conservator uses rubber diaphragm to separate transformer oil from the outside atmosphere, and provides space for transformer oil to expand and contract.

3. The corrugated oil conservator uses a metal expander composed of metal corrugated sheets to separate the transformer oil from the outside atmosphere, and provide the transformer oil with space for thermal expansion and contraction. The corrugated oil conservator is divided into two types: inner oil type and outer oil type. The inner oil type has better performance but larger volume.

6. Cooling method of oil-immersed transformer

1. Symbols representing cooling methods

The first letter: O—mineral oil, K—synthetic insulating fluid, L—insulating gas.

The second letter: N - natural convection circulation, F - forced oil circulation, D - forced guide circulation.

The third letter: A - air, W - water.

Fourth letter: N - natural convection, F - forced circulation (fan, pump).

2. Examples

ONAN—Free Cooling

ONAF - air cooling

OFAF—Forced Oil Circulation Air Cooling

ODAF—Forced Oil Circulation Guided Cooling

Seven, transformer bushing

1. Pure porcelain insulating bushing of 40kV and below

This kind of casing has two structures of guide rod type and cable type. The guide rod type is used for low-voltage bushings of transformers; the cable-through type is used for 10~20kV high-voltage outgoing lines.

2. High current bushing of 40kV and below

This kind of bushing has two kinds of structures: guide rod type and capacitive type. The guide rod type pure ceramic bushing is used for the low-voltage winding outlet of medium-capacity generator transformers; the capacitive bushing is used for the low-voltage winding outlet of large generator transformers.

3. Oil-paper capacitive bushing of 66kV and above

The inner insulation of this sleeve is a capacitor core made of insulating paper and aluminum foil alternately wound. The capacitor core and the porcelain sleeve are filled with insulating oil. The connection between the sleeve and the winding has two types of guide rod type and cable type. kind of structure. The oil-paper capacitor core is alternately wound on the conductive tube by 0.08~0.12mm thick cable paper and 0.01mm thick aluminum foil.

4. Tape-paper capacitive bushings of 66 kV and above

The inner insulation of this sleeve is a capacitor core formed by alternately winding adhesive paper and aluminum foil. The capacitor core and the porcelain sleeve are filled with insulating oil, and the lower part of the sleeve does not need a porcelain sleeve. However, the tanδ of this kind of casing is large, and the adhesive paper is easy to crack and generate partial discharge, and production has been stopped at present.

5. Resin cast capacitor bushing

The main insulation of this sleeve is also a capacitor core formed by alternately winding insulating paper and aluminum foil, and epoxy resin is poured on the outside to become a solid insulating sleeve. This kind of bushing can be used as oil-gas bushing, the upper part is set in the pipeline of GIS, and SF6 gas is filled in between; the lower part is immersed in transformer oil.

8. Voltage regulation method of power transformer

1. Voltage regulation method

There are two types of voltage regulation methods for transformers: non-excitation voltage regulation and on-load voltage regulation. Non-excitation voltage regulation, also known as no-load voltage regulation, is to regulate the voltage when the transformer is stopped and without load; The non-excitation voltage regulating device is called a no-load tap-changer; the on-load voltage regulating device is called an on-load tap-changer.

2. On-load voltage regulation position

There are three types of transformer on-load voltage regulation positions: neutral point voltage regulation, medium voltage line end voltage regulation and high voltage coil line end voltage regulation. Among them, the structure and process of neutral point voltage regulation are relatively simple, and there are many applications.

3. On-load voltage regulating switch

The pressure regulating switch is also a tap changer. At present, the quality of domestically produced on-load tap-changers is not good enough, and most of the on-load tap-changers rely on imports, of which more are imported from German MR and Swedish ABB.

Nine, transformer oil

1. The composition of transformer oil

Transformer oil is mineral oil, which is a mixture of many hydrocarbon molecules of different molecular weights, which are mainly hydrocarbon compounds such as alkanes, naphthenes and a small amount of aromatic hydrocarbons.

2. The function and grade of transformer oil

Transformer oil for insulating oil of oil-immersed transformers. Transformer oil not only has the function of insulation, but also has the function of heat dissipation.

Transformer oil is divided into No. 25 oil and No. 45 oil according to its freezing point. The freezing point of No. 25 oil is minus 25°C; the freezing point of No. 45 oil is minus 45°C.

No. 25 transformer oil is paraffin-based oil, and No. 45 transformer oil is naphthenic oil. In the past, No. 45 transformer oil had to be imported from abroad, and now Xinjiang Karamay Refinery can also produce it.

10. Manufacturing process of power transformer

The power transformer consists of two parts: the body and the accessories. The body is composed of coil, insulating parts, iron core, tap changer, transformer oil and oil tank. The accessories of the transformer include oil conservator, cooler, bushing, gas relay, pressure releaser and thermometer. Among them, coolers, insulating oil, bushings, tap changers, gas relays, pressure releasers and thermometers are all purchased from outside. The following only briefly introduces the manufacturing processes of several main components.

1. Coil winding: installation of winding skeleton - winding coil - wire welding - insulation package - coil shaping - coil test.

2. Iron core assembly: cutting silicon steel sheet - deburring - stacking iron core - installing pull plate and shielding - binding iron core - iron core test - installing iron core clips.

3. Insulation parts processing: insulation parts cutting - deburring - chamfered corners - moisture-proof treatment.

4. Processing of fuel tanks and oil storage tanks: steel plate cutting - welding of fuel tanks and oil storage tanks - rust removal - sandblasting - primer painting - painting - mechanical strength test.

5. General assembly: install the iron core - install the fuel tank pipeline - set the coil - stack the iron yoke - install the tap changer - welding lead wire - wrap the lead wire insulation - semi-finished product test - body drying - finishing body - fuel tank assembly - accessory assembly - Oil filling - sealing test - hot oil circulation - static placement.

11. Factory test of power transformer

The factory test of power transformer is divided into three types: routine (factory) test, type test and special test. Routine test is a test item that must be carried out for each transformer when it leaves the factory, and is usually called a factory test; type test is a test item carried out by sampling 1~2 transformers in a type of product; special test is proposed by the user. , and the test items agreed with the manufacturer.

1. Basic requirements and regulations for high voltage insulation test

The transformer windings are tested according to the highest operating voltage Um and the corresponding insulation level. The following table is the insulation test items stipulated in the national standard GB1094.3-2003 "Power Transformer Part III: Insulation Level, Insulation Test and External Insulation Air Gap" .

2. Routine (factory) test items

(1) Winding DC resistance measurement: measurement on all tap terminals.

(2) Ratio measurement: measure at all tap positions.

(3) Wiring group detection: test at the rated tap position.

(4) Measurement of insulation resistance, absorption ratio and polarization index: Only transformers of 220kV and above can measure the polarization index.

(5) Winding tanδ and capacitance test: 35kV and above transformers should be tested for tanδ. .

(6) Bushing tanδ and capacitance test: 66kV and above capacitive bushings must be tested for tanδ and capacitance

(7) Transformer oil test: oil analysis, dielectric strength, tanδ, chromatographic analysis and other items, 750kV and above transformers should also be tested for particle size in oil. Moreover, oil chemical analysis and oil chromatographic analysis were repeated throughout the test process.

(8) No-load loss and no-load current measurement: Carry out the test under the rated voltage wiring.

(9) Measurement of load loss and short-circuit impedance: test under rated voltage wiring.

(10) Partial discharge test: The discharge amount is not used as an assessment, but only as a reference for whether a high-voltage test can be performed.

(11) Lightning full-wave impulse test: 220kV and above, 120MVA and above transformers.

(12) Operational impact test: transformers of 330 kV and above.

(13) Inductive withstand voltage test with partial discharge measurement: transformers of 110 kV and above.

(14) External construction frequency withstand voltage test of low-voltage winding and neutral point.

(15) Partial discharge test: This test is an assessment test for the factory test value.

(16) Electricity measurement of oil flow: transformers with oil pumps of 330 kV and above.

(17) Partial discharge test of rotating oil pump: transformers with oil pump of 330 kV and above.

2. Type test items

(1) Temperature rise test.

(2) The lightning clipping wave has been tested.

(3) Lightning full-wave impact test at neutral point.

(4) Radio interference test

3. Special test items

(1) Sound level measurement.

(2) Zero-sequence impedance measurement of three-phase transformers.

(3) Harmonic measurement of no-load current.

(4) Measurement of the power absorbed by the fan motor and the oil pump motor.

(5) Measurement of transient voltage transfer characteristics.

(6) Withstand short-circuit capability test.

CONTACT US

Take advantage of our unrivaled knowledge and experience, we offer you the best customization service.

LEAVE A MESSAGE

Please fill out and submit the form below, we will contact you in 48 hours, thank you!

RECOMMENDED

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.